Assembly line for automobile rope wheel lifer pulley assembly and method thereof

A pulley assembly and lifter technology, which is applied to the assembly line field of the pulley assembly of the sheave lifter of an automobile, can solve the problems of inability to realize intelligent control, low control precision, low work efficiency, etc., and achieves good theoretical research value and application significance. , The effect of improving production efficiency and product qualification rate, reducing labor time and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

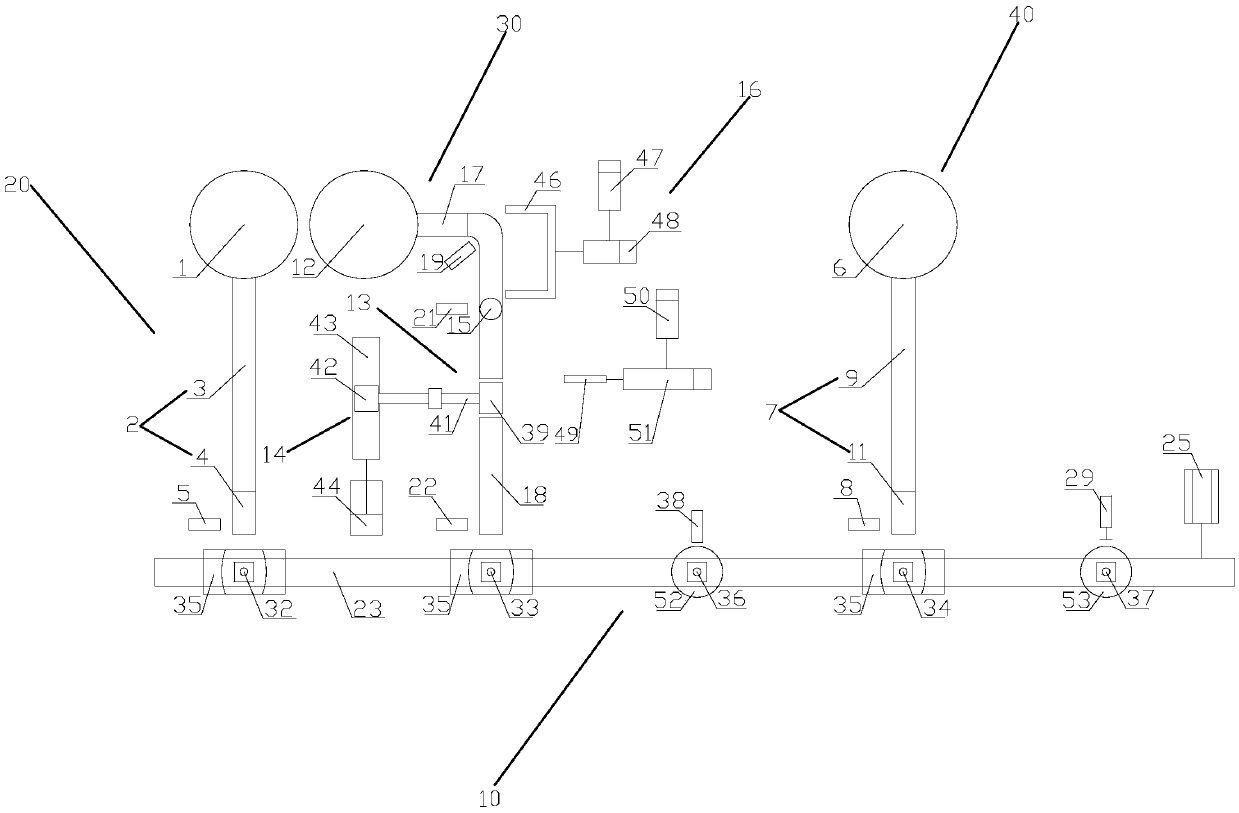

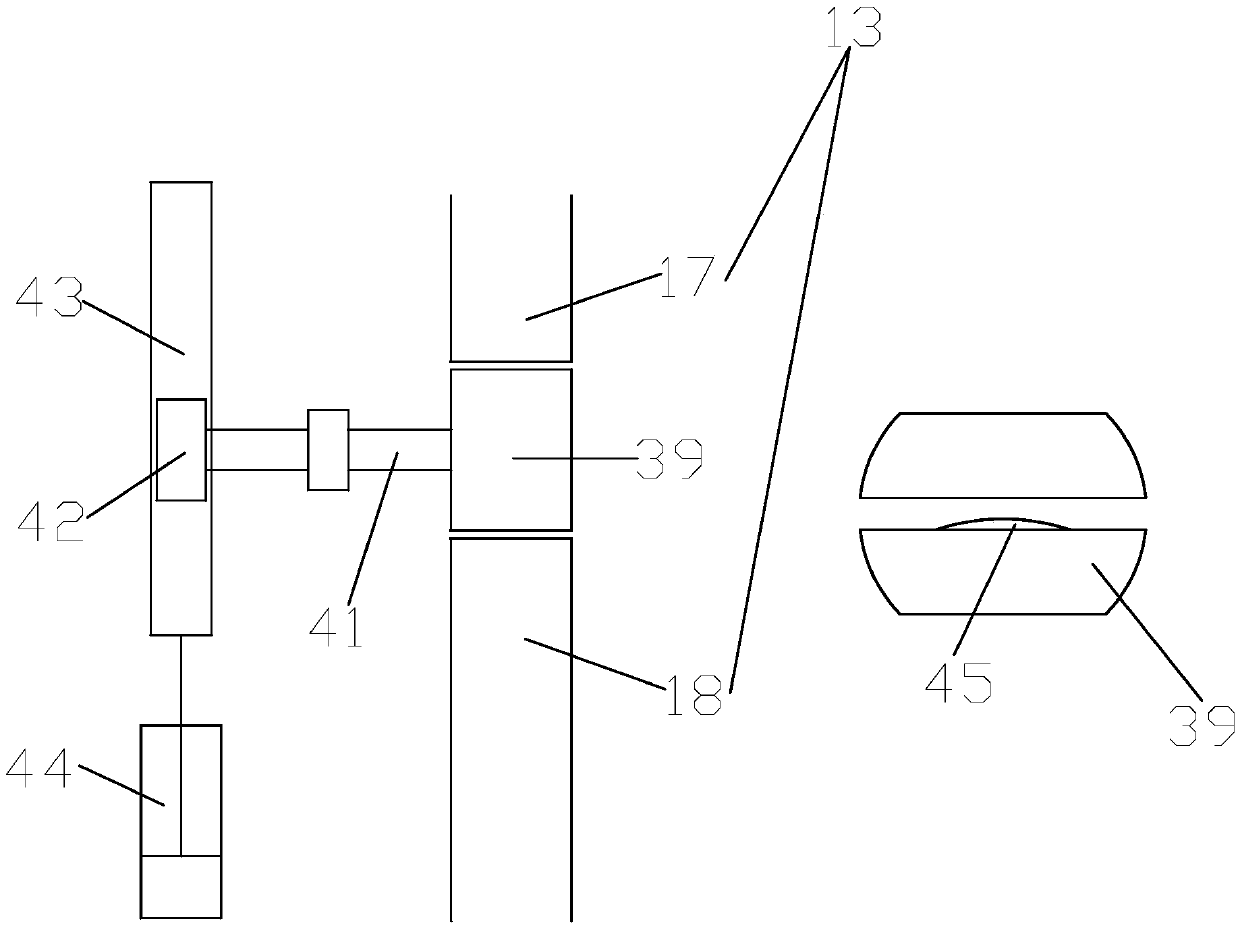

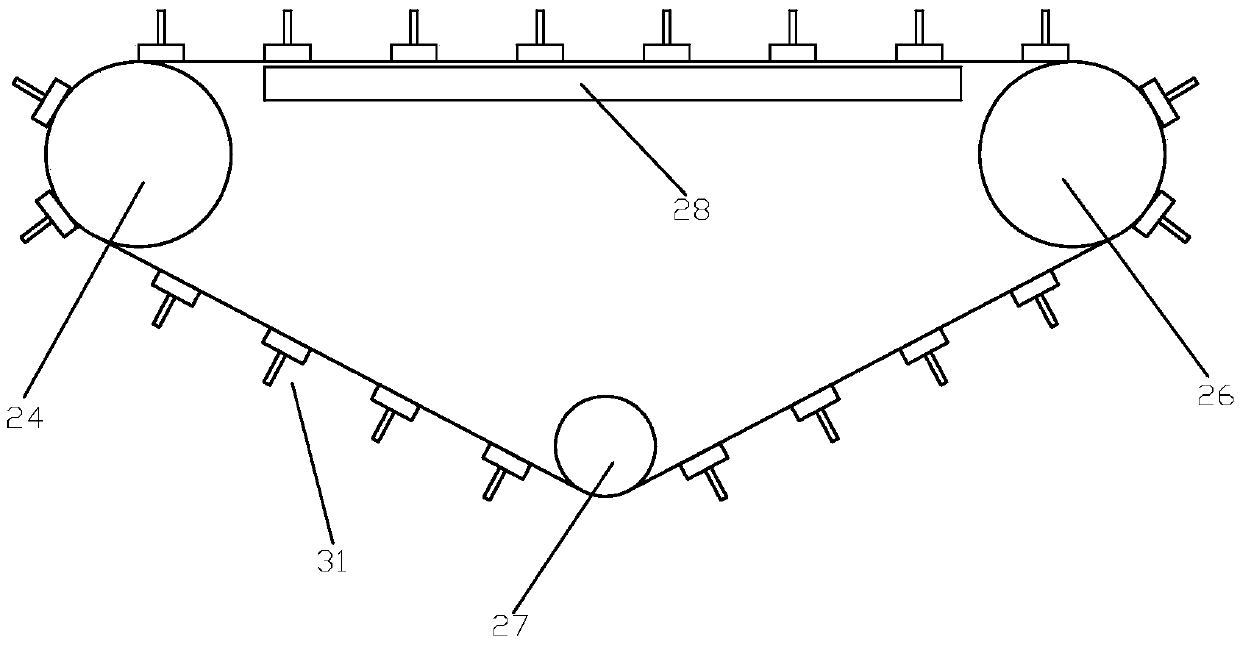

[0030] Such as Figure 1-5As shown, the present invention discloses an assembly line for a pulley assembly of an automobile rope wheel lifter, the assembly line is used to assemble a pulley assembly composed of rivets, pulleys and pulley seats, including a sprocket for switching between stations Mechanism 10, the rivet feeding mechanism 20, the pulley feeding mechanism 30 and the pulley base feeding mechanism 40 that are arranged on one side of the sprocket mechanism and connected with the sprocket mechanism 10 in turn; the sprocket mechanism 10 is provided with several stations 31, The several stations 31 can be displaced synchronously with the rotation of the sprocket mechanism 10 .

[0031] to combine figure 1 As shown, the rivet feeding mechanism 20 includes a rivet vibrating screen 1, a rivet track 2 connected to the rivet vibrating screen 1, and a first photoelectric sensor 5 located at the outlet of the rivet track 2; wherein, the rivet track 2 includes a rivet incline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com