Oil seal underwater propeller

A thruster and oil seal technology, applied in the field of underwater thrusters, can solve the problems of reducing thruster efficiency, large output torque loss, wear of magnetic coupling mechanism, etc., and achieves the effects of novel structure, high reliability and reduced thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

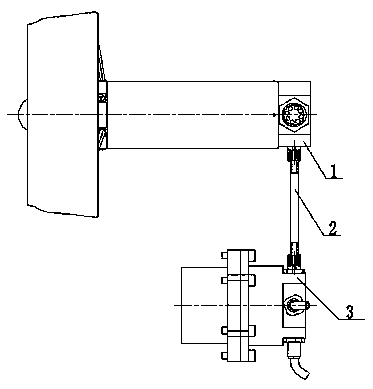

[0019] The invention provides an oil-sealed underwater propeller, which can improve the propeller wear problem, improve the reliability of the sealing structure, reduce the thickness of the propeller shell, solve the heat dissipation problem of the motor at the same time, and avoid the loss of torque transmission, thereby improving the performance of the entire propeller. performance.

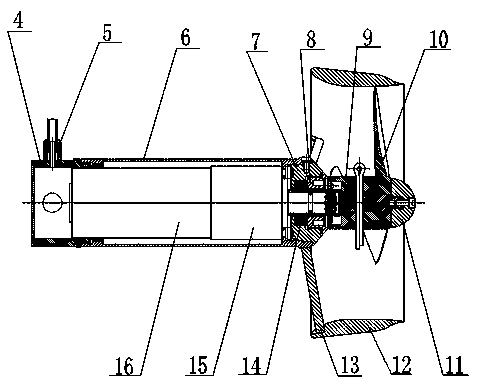

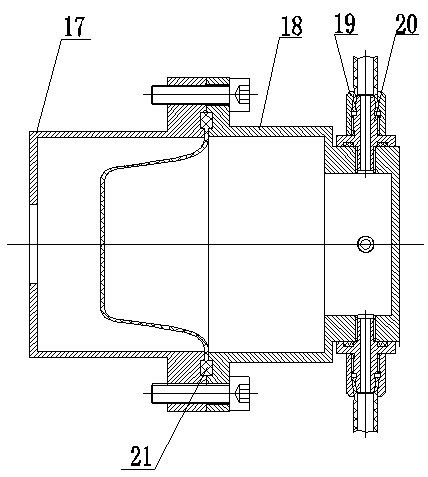

[0020] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0021] Such as Figure 1-Figure 3 As shown, an oil-sealed underwater thruster includes a propeller 1, a compensator 3, and also includes an oil pipe 2, a head cover 4, a propeller oil pipe fixing sleeve 5, a casing 6, an oil seal gland 7, and an oil seal outer retaining ring 8 , output shaft 9, propeller 10, sacrificial anode 11, shroud 12, shroud support rod 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com