Large special resin polymerization kettle for polyvinyl chloride

A technology of polyvinyl chloride and polymerization kettle, applied in the field of chemical machinery, can solve problems such as large heat of polymerization, and achieve the effect of good cooling effect, ensuring stability and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

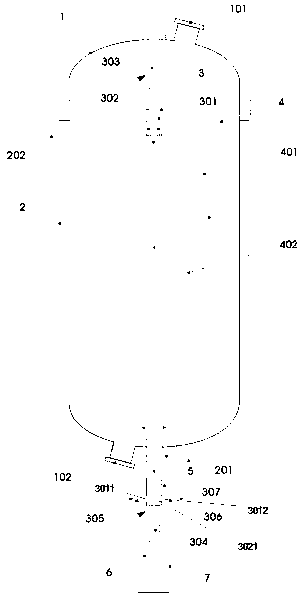

[0025] Its specific implementation method is as follows: when the polymerization kettle is working, the material is input into the inside of the polymerization kettle body 1 from the feed port 101 through a certain pressure, and after a certain amount of material is input, the transmission device 6 is opened and drives the stirring shaft 3 and the stirring paddle 4 Stir, at this time, the material in the polymerization kettle body 1 starts to polymerize under the set pressure and temperature, and the material after the reaction is output from the discharge port 102; the heat generated by the polymerization reaction is cooled by the internal stirring system and the external jacket The cooling operation mode of the stirring system is that the cooling water flows in from the cooling water inlet 305 through a certain power, and enters the interlayer formed by the outer stirring shaft tube 301 and the central shaft tube 302 through the sleeve 307 and the cooling water inlet 3011 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com