A preparation method of high toughness and low water absorption carbon-oxygen cross-linked polyvinyl acetal insulating material

A technology of polyvinyl acetal and low water absorption, which is applied in the field of polymer materials to achieve the effects of shortening condensation time, stable quality and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] A continuous preparation method of a carbon-oxygen cross-linked polyvinyl acetal insulating material with high toughness and low water absorption, the steps are as follows:

[0036] Step 1: Preparation of polyvinyl alcohol-acetaldehyde water emulsion

[0037] Add 650 parts by mass of water into the dissolution tank, add 52 parts by mass of polyvinyl alcohol under stirring, keep warm at 25°C for 1.5h, raise the temperature to 95°C and keep warm for 1.5h, and when the temperature is lowered to 65°C, filter to obtain polyvinyl alcohol Vinyl alcohol aqueous solution, and then 10 parts by mass of acetaldehyde aqueous solution was added to the solution at a temperature of 35°C, and stirred for 60 minutes to obtain a polyvinyl alcohol-acetaldehyde aqueous emulsion

[0038] Step 2: Preparation of polyvinyl alcohol-acetaldehyde-hydrochloric acid aqueous emulsion

[0039] Cool the uniformly stirred polyvinyl alcohol-acetaldehyde water emulsion to 13°C, and add a hydrochloric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

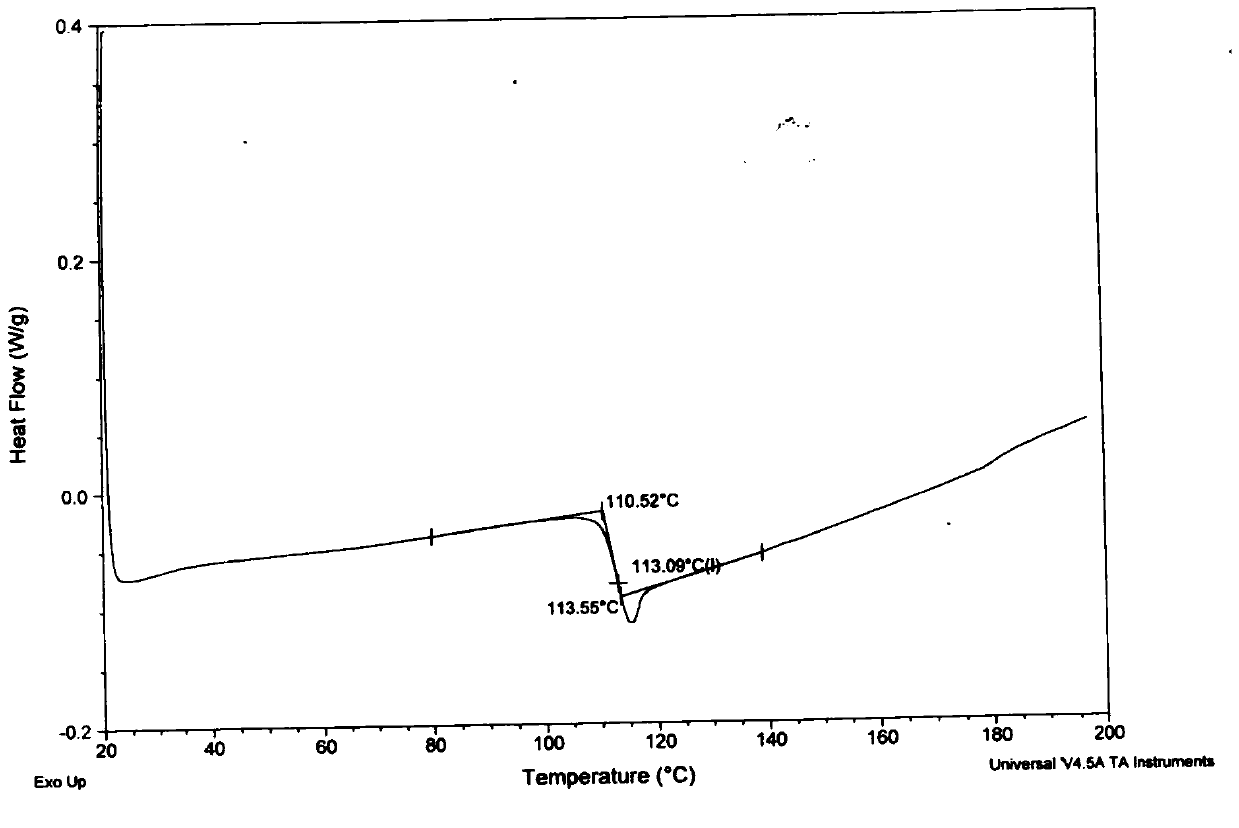

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com