Waste plastic and molten salt cracking tower

A waste plastic and molten salt technology, which is applied in plastic recycling, pyrolysis reaction, preparation of liquid hydrocarbon mixture, etc., can solve problems such as uneven heat transfer, difficult mixing of molten salt and waste plastic, etc., to achieve sufficient cracking process, Improve heat transfer effect and increase heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

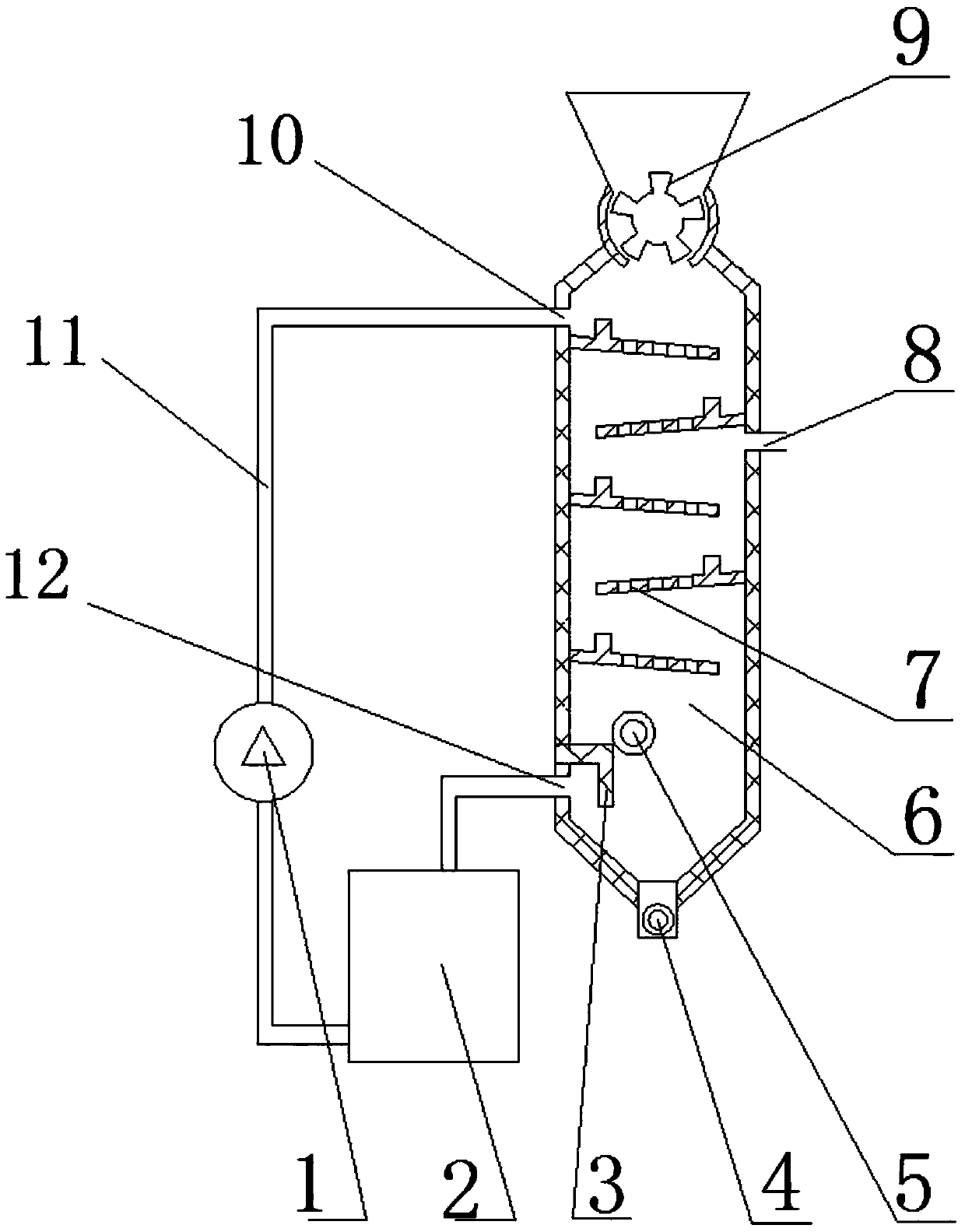

[0014] The structure of the waste plastics molten salt pyrolysis tower of the present invention, as figure 1 Shown, comprise molten salt furnace 2 and the cracking tower tower body 6 that is connected with molten salt furnace 2 by salt delivery pipe 11, cracking tower tower body 6 is made of refractory material and heat insulating material, and the top of cracking tower tower body 6 is provided with There is a rotor feeder 9, and the rotor feeder 9 has a sealing function and an air removal function, and can evenly send waste plastics with a particle size of less than 30mm into the pyrolysis tower body 6; The salt inlet 10 is provided with a molten salt outlet 12 at the bottom, and several trays 7 are sequentially arranged in the cracking tower body 6 from the molten salt inlet 10 to the molten salt outlet 12, and the cracking tower body 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com