Static railway track assembly overall dimension and damage optical detection system

A technology of optical detection and railway track, which is applied in the direction of track, track maintenance, track superstructure, etc., and can solve the problems of low detection efficiency and low detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

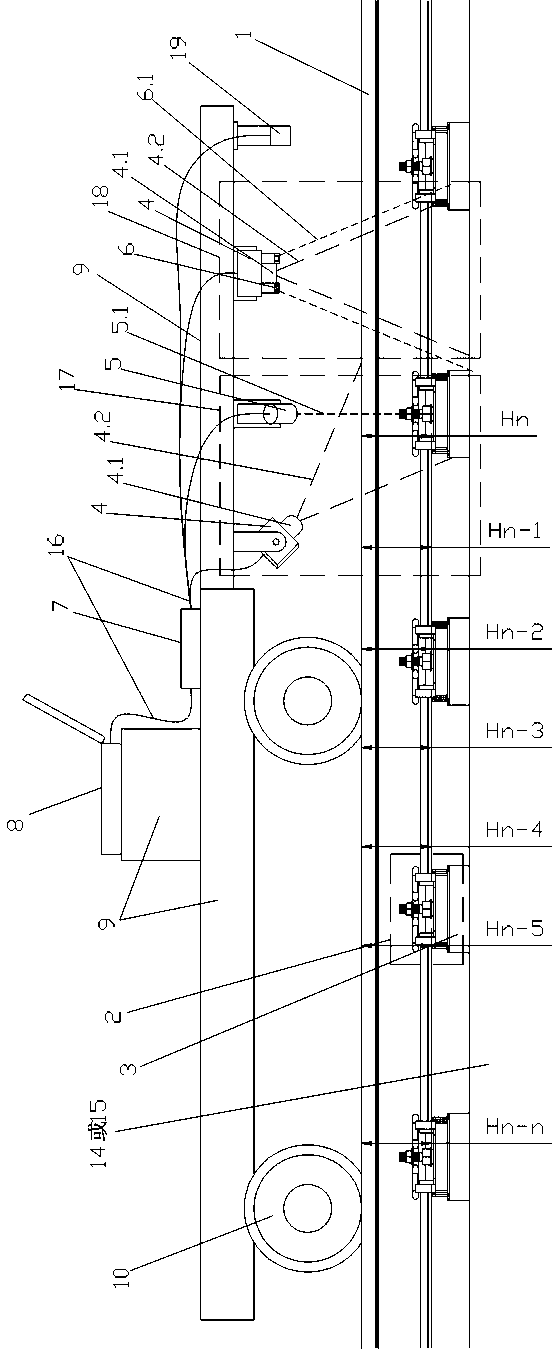

[0065] see figure 1 , a static railway track component outline dimension and optical detection system for disease, this system is used for the detection of static railway track component and track disease, the system includes rail and rail fastener combined contour section size optical detection sub-system 17, track disease Optical detection sub-system 18, image processing card 8, computer (or notebook computer or palmtop computer) 9, data, power supply cable 16 and walking type mechanical frame 9, mileage sensor 10, distance sensor 19 composition, also can rail and rail The optical detection sub-system 17 of the profile and section size of the fastener assembly or the optical detection sub-system 18 of the track defect is separately installed on the walking mechanical frame 9 and the image processing card 8, computer (or notebook computer or palmtop computer) 9, data and power cables 16. The distance sensors 19 are connected to realize corresponding detection functions.

Embodiment 2

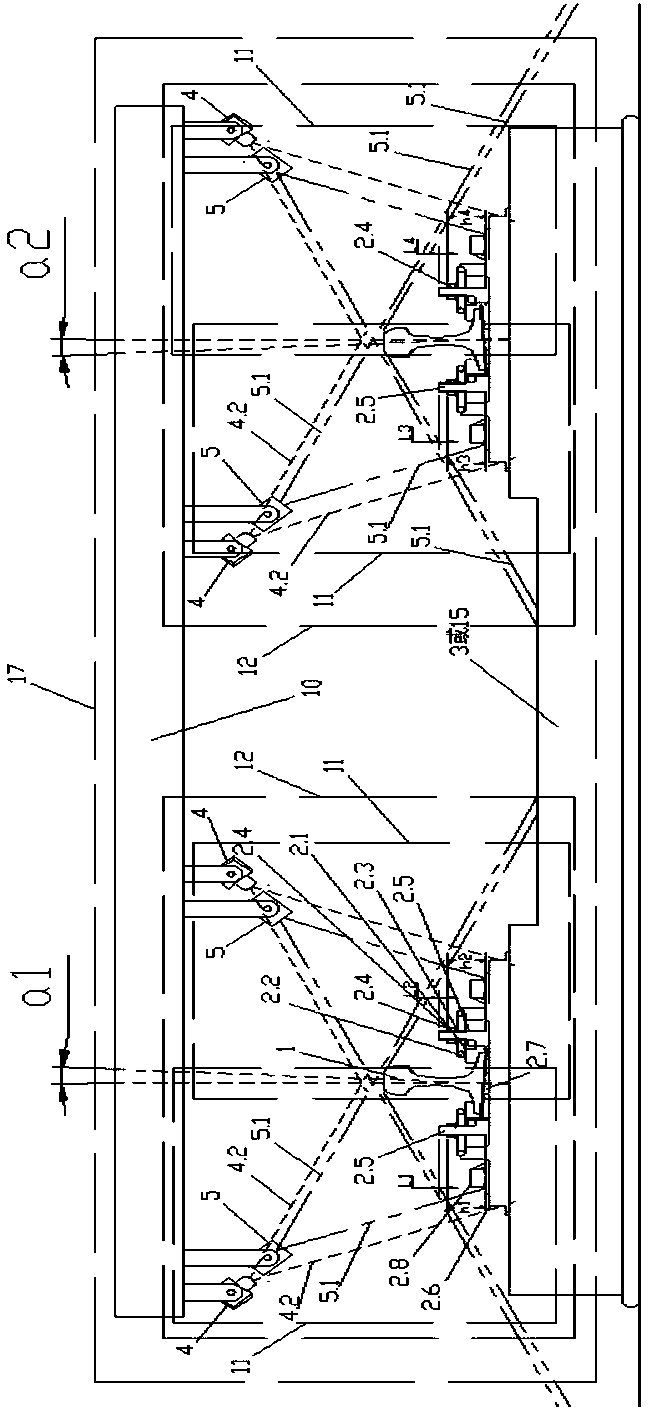

[0067] see figure 2 An optical detection sub-system 17 for the outline size and defect optical detection system of a static railway track component outline size and rail fastener combined outline section size 17, including a high-speed camera 4, an inline strong light source 5, an image processing card 8, and a computer ( Or notebook computer or palmtop computer) 9, data, power supply cable 16, walking type mechanical frame 9, mileage sensor 10, distance sensor 19, described inline glare light source 5 and high-speed camera 4 are arranged on rail side, so A high-speed camera 4 for optical detection and an in-line strong light source 5 constitute a set of optical detection group 11 for the combined contour section size of rails and rail fasteners. 11 is set at a position higher than the rail surface on the side of the rail 1, and the two sets of rails and rail fasteners on both sides of the same rail 1 are respectively located on the two sides of the same rail 1. The optical d...

Embodiment 3

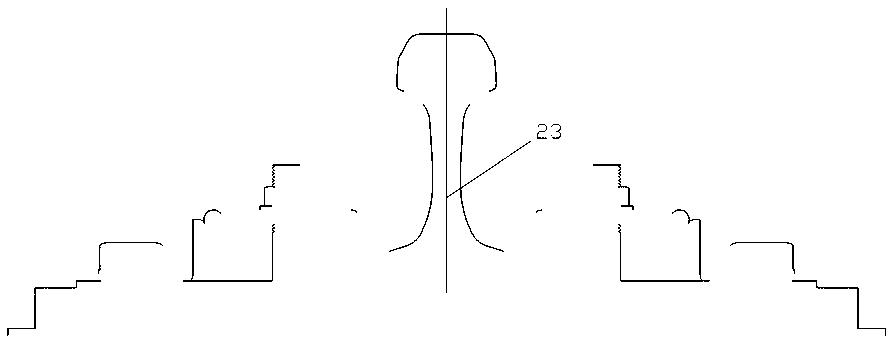

[0078] The high-speed camera 4 for optical detection and a group of ring-shaped strong light sources 6 constitute a set of track defect optical detection unit 13, and the track defect optical detection unit 13 is arranged above the top surface of the rail 1, and the optical detection uses high-speed Camera 4 is connected with image processing card 8 and computer (or notebook computer or palmtop computer) 9 via data and power cables 16 . Said, the image collected by the high-speed camera 4 is transmitted to the image processing card 8 through the data and the power cable 16, and then transmitted to the computer (or notebook computer or palmtop computer) 9 after the sharpening of the image boundary and the calculation of the optical center of gravity, After the image information is processed by the computer (or notebook computer or palmtop computer) 9, the information and images of the local wear on the top surface of the rail, the falling block 1.7 and the rail crack 3.4 are obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com