Aluminum formwork vertical profile corrugated joints and aluminum formwork system

A technology for connecting nodes and aluminum formwork, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc. Improved, easy and fast construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

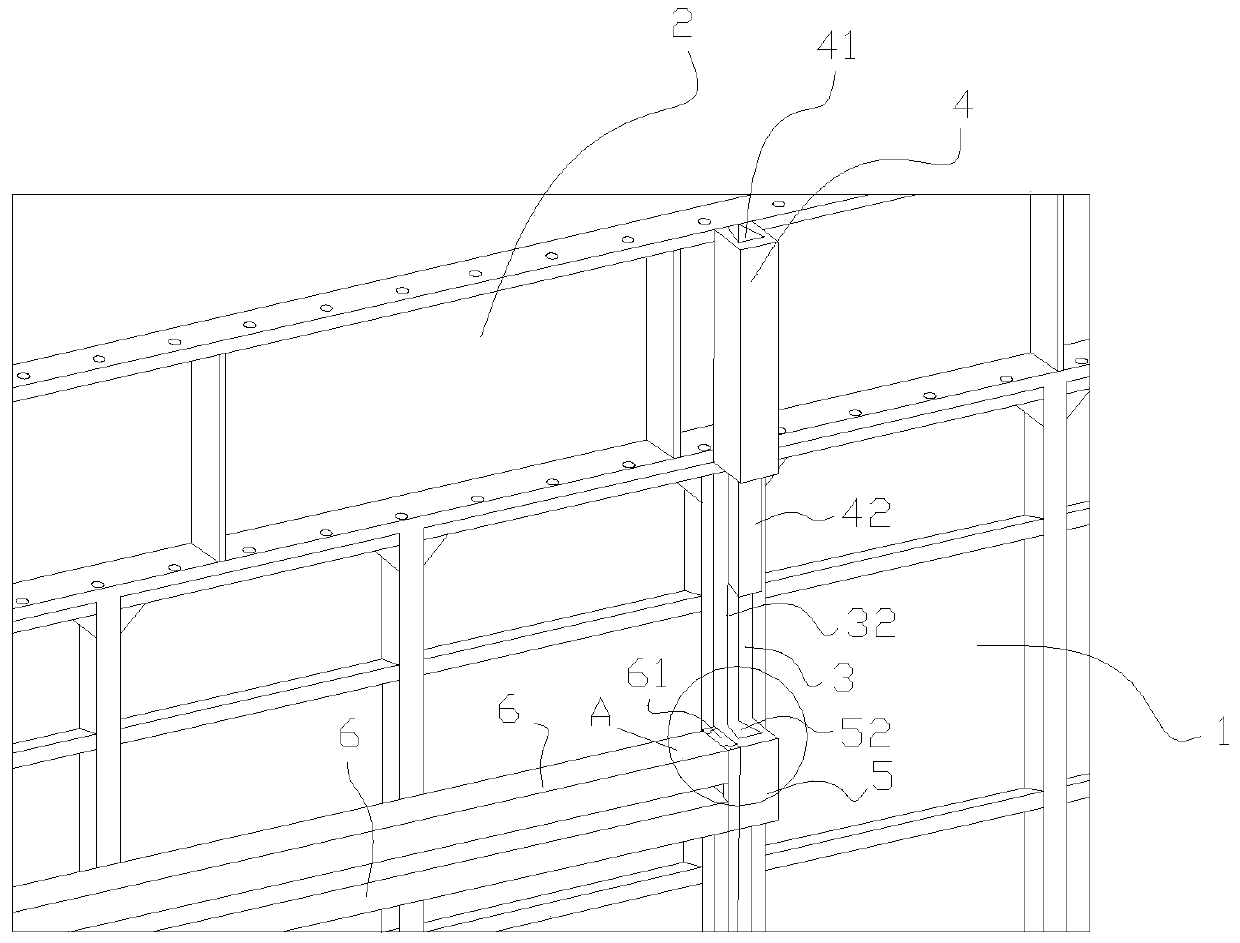

[0019] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

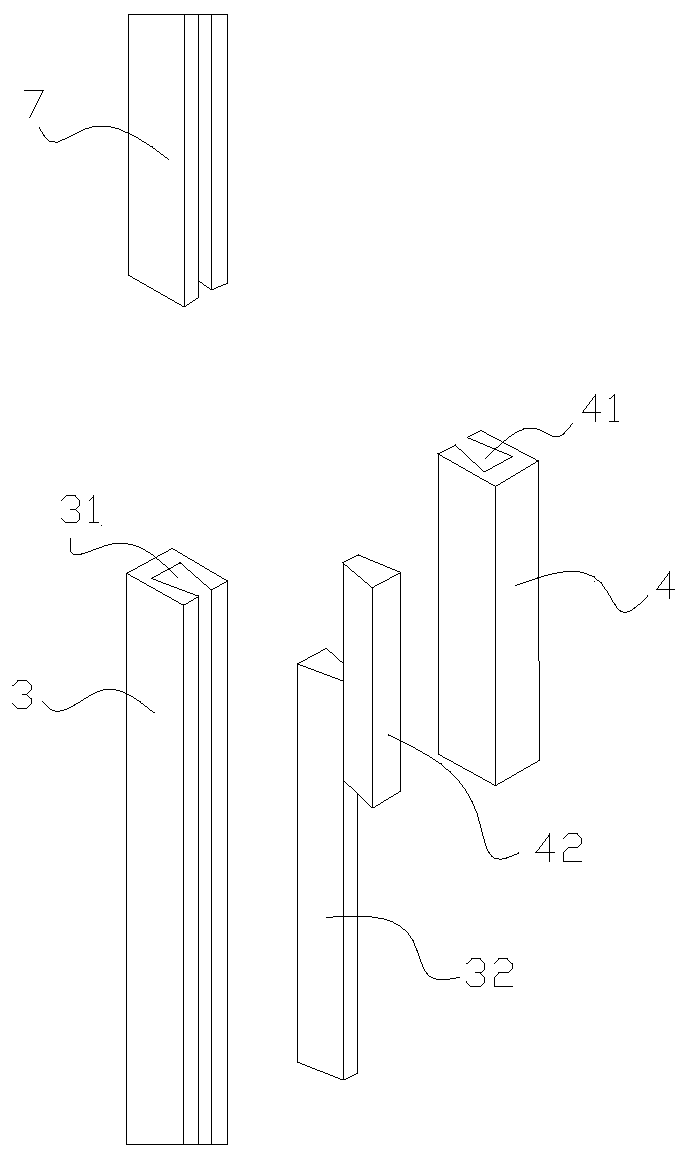

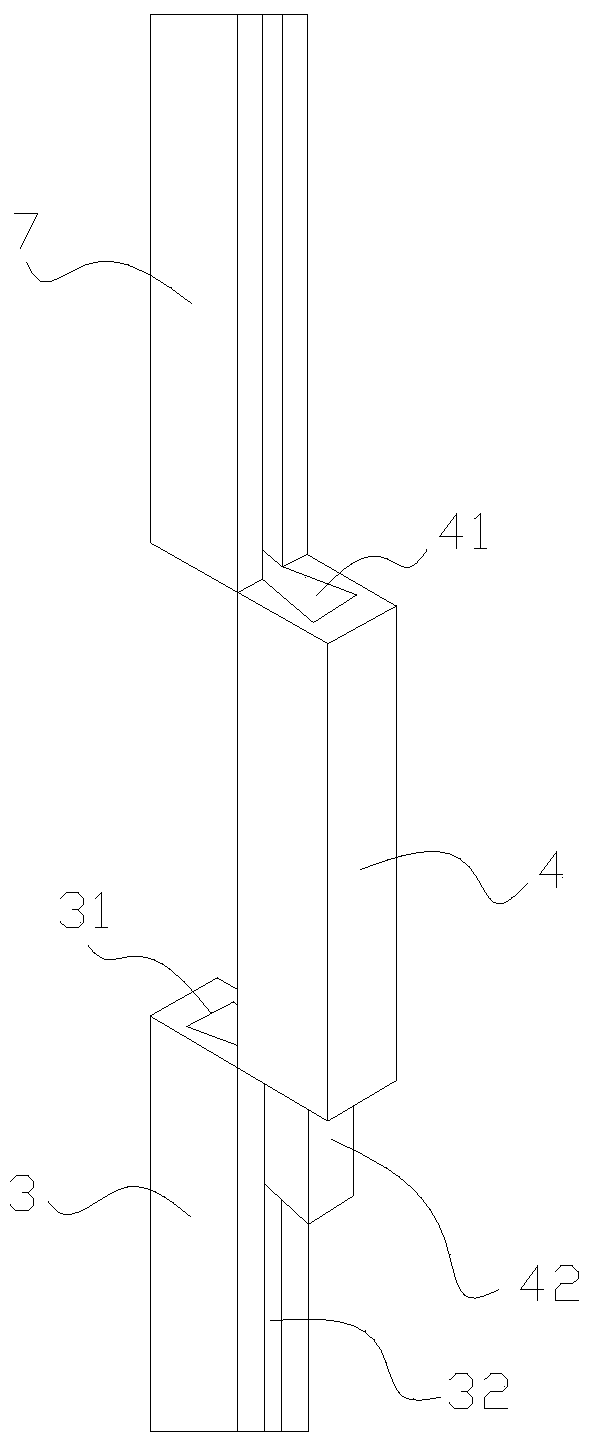

[0020] refer to Figure 1 to Figure 3 , the embodiment of the present invention provides an aluminum formwork vertical profile corrugation connection node, including a main formwork 1 and a transfer formwork 2 located above the main formwork 1, and a first vertical profile corrugation 3 is vertically arranged along the surface of the main formwork 1 , a first card slot 31 is longitudinally provided in the first vertical profile corrugated 3, the cross section of the first card slot 31 is trapezoidal, and the first card slot 31 is inlaid with a first insert that fits the first card slot 31. Solid slider 32;

[0021] A second vertical profile corrugated 4 is vertically arranged on the transfer formwork 2, and a second clamping groove 41 is longitudinally arranged inside the second vertical profile corrugated 4. The cross section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com