Vacuum fixator used fixedly and repeatedly

A fixer and vacuum technology, applied in the direction of connecting components, suction cups, mechanical equipment, etc., can solve the problems of shape deformation of the suction cup edge, lack of good recovery ability, unable to provide bonding force, etc., and achieve the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in combination with specific embodiments and accompanying drawings, and the advantages and characteristics of the present invention will become clearer along with the description.

[0045] In order to achieve the above object, the present invention specifically cites preferred embodiments, and cooperates with the accompanying drawings, which are described in detail as follows:

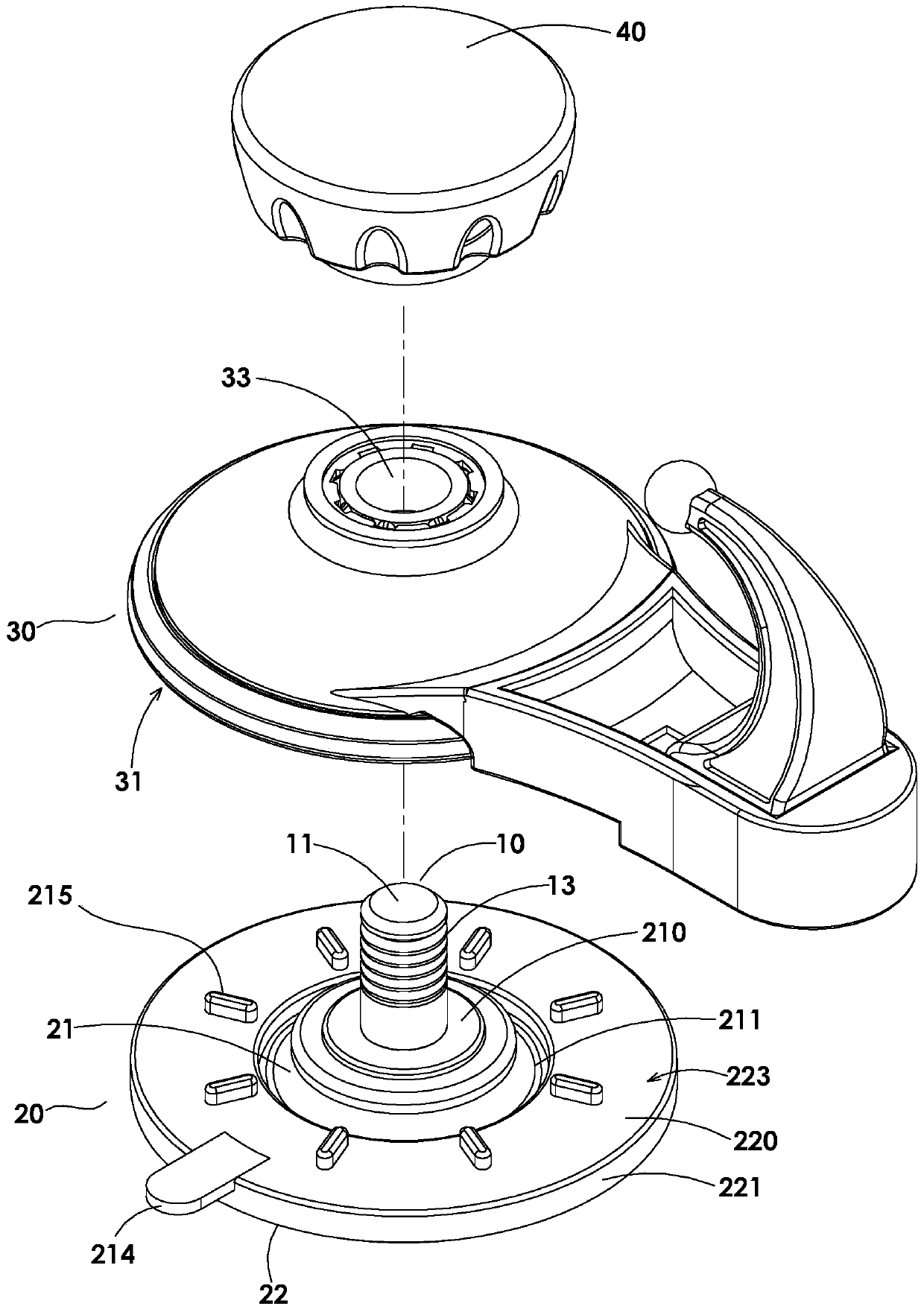

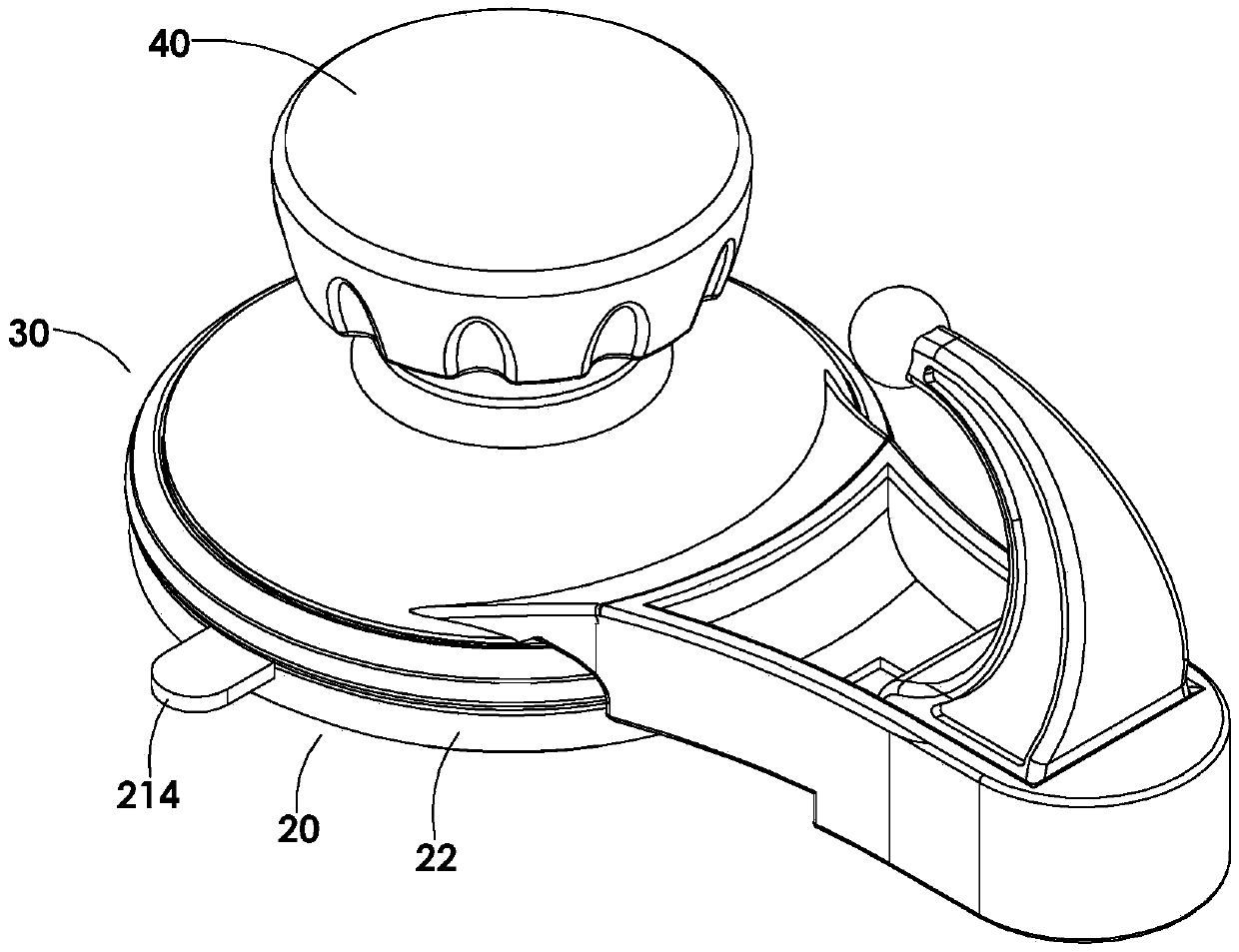

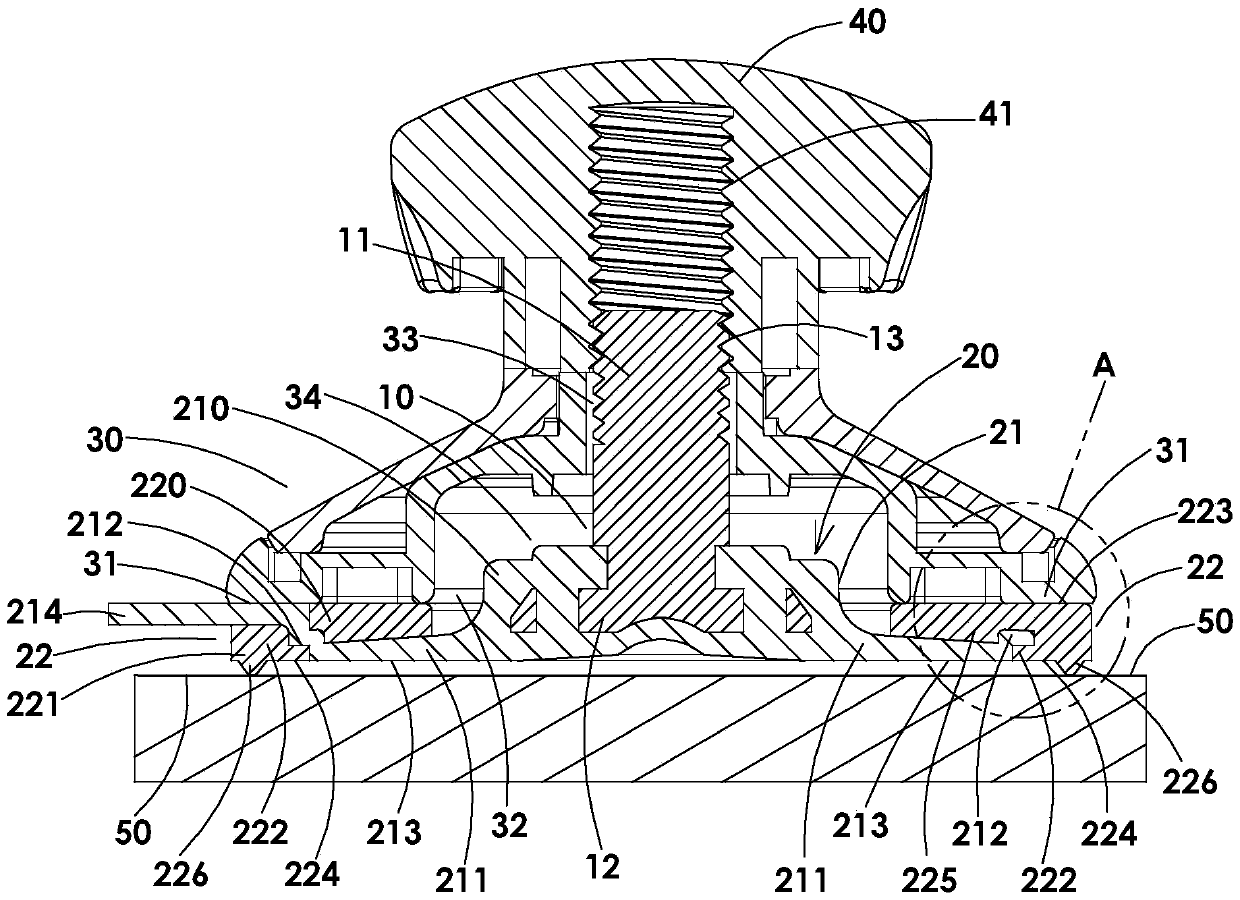

[0046] A vacuum holder for repeated fixation use, such as figure 1 , 2 , 3, 4, including:

[0047] A pulling member 10 is made of polyoxymethylene (POM) hard and rigid plastic material, and has a pull rod 11, and one end of the pull rod 11 is formed with a pull plate body 12;

[0048] A suction cup part 20 includes a suction cup body 21 and a sealing frame ring body 22; the suction cup body 21 is that the pulling part 10 is placed in a plastic mold (not shown), and is made of a flexible elastic polymer (plastic) material The flexible disk-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com