Novel assembled type fan coupler

An assembled and coupling technology, applied in the direction of couplings, rigid shaft couplings, clutches, etc., can solve the problems of high noise, low production efficiency, easy failure, etc., and achieve the effect of avoiding damage and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

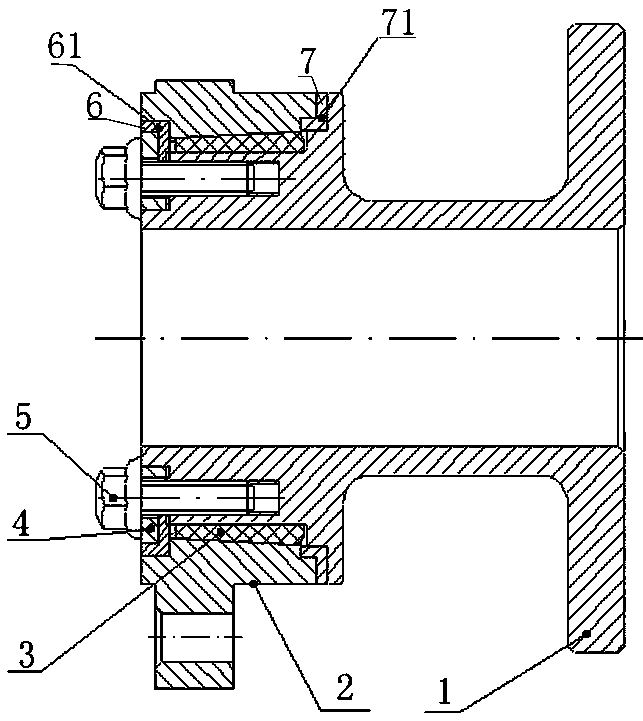

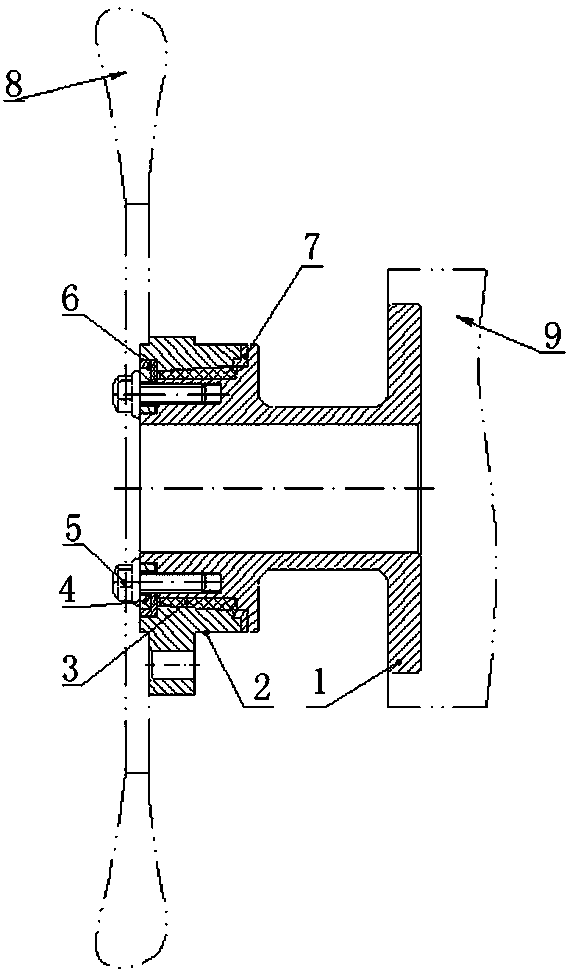

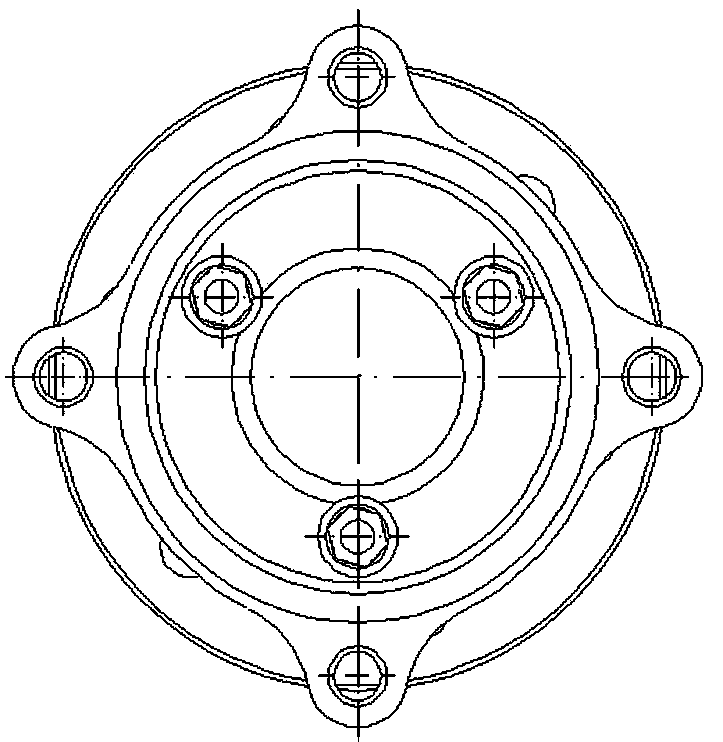

[0022] The present invention as figure 1 , figure 2 , image 3 shown.

[0023] A new type of assembled fan coupling, including an outer flange 1, an inner flange 2, the outer flange 1 is connected to the engine 9, the inner flange 2 is connected to the fan 8, the outer flange 1 and the inner flange 2 Both are equipped with an upper stop 6 and a lower stop 7, the outer flange 1 and the inner flange 2 are set together and form a cavity through the upper stop 6 and the lower stop 7, and a rubber shock absorber is installed inside the cavity 3. The outer flange 1 and the inner flange 2 are connected together through the bolt 5 and the end cover 4, and the rubber damping block 3 is press-fitted.

[0024] The cavity formed by the outer flange 1 and the inner flange 2 is a conical cavity, wherein the taper of the conical cavity faces the direction of the end cover 4, and the corresponding rubber shock absorber 3 is also taper in the same direction; the rubber shock absorber 3 he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com