High-performance irregular toothed spiral finned tube

A fin tube and high-performance technology, which is applied in the fields of industrial waste heat utilization, energy saving and emission reduction, can solve the problems of high proportion of high energy consumption industries and low level of energy utilization in industrial sectors, and achieve high processing efficiency, less processing technology changes, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings.

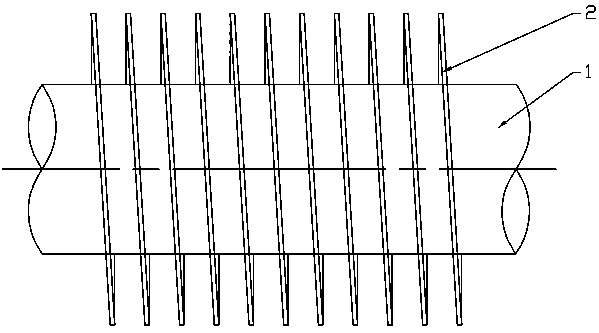

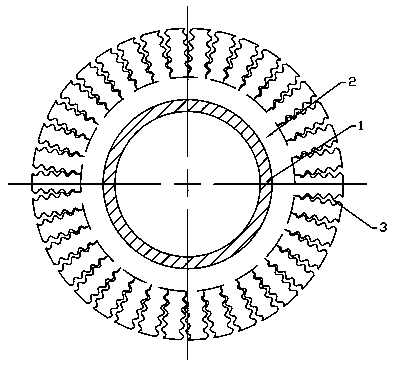

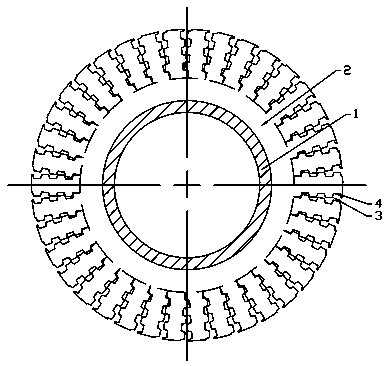

[0017] Such as figure 1 As shown, the high-performance special-shaped toothed spiral fin tube provided in this embodiment includes a base tube 1 and fins 2 arranged on the outer surface of the base tube 1, and the fins 2 are provided with several notches 3 , the edge of the notch 3 is provided with grooves, and the fins 2 are spiral fins.

[0018] Such as figure 2 As shown, the shape of the groove is wavy.

[0019] A plurality of notches 4 are provided on the groove, and the notches are one of semicircle, triangle, rectangle and trapezoid. Such as image 3 As shown, the shape of the notch is trapezoidal.

[0020] The high-performance special-shaped toothed spiral fin tube provided in this embodiment uses a special tool to process the flat steel strip with a certain thickness into teeth of different shapes and angles, and then uses a high-frequency welding process t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com