Modular wide hot stamping machine

A hot stamping machine, modular technology, applied in printing presses, rotary printing machines, printing and other directions, can solve the problems of shorter product update cycle, no longer adapt to hot stamping process, not adapt to diversification, high-speed hot stamping, etc., to achieve the update cycle Short, improve the quality of bronzing, prolong the effect of contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in conjunction with the drawings and descriptions of the specification.

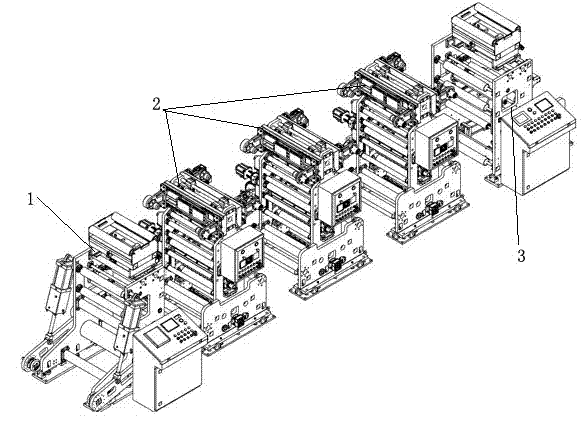

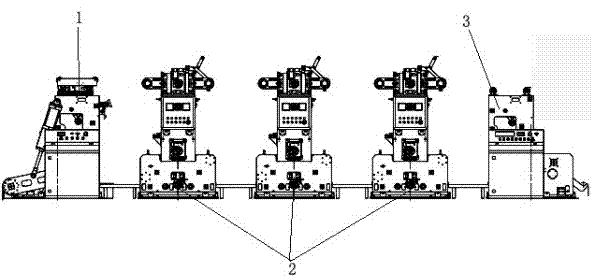

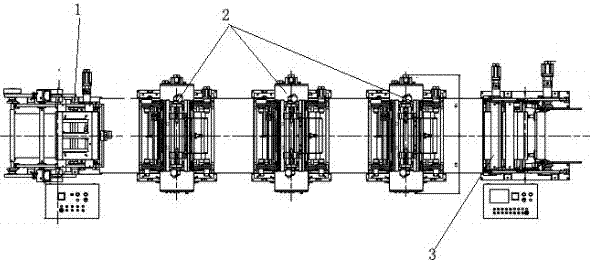

[0040] like Figure 1-12 As shown, this embodiment takes the three-color hot stamping of tipping paper as an example. The hot stamping machine includes a tipping paper unwinding unit, a paper deviation correction and guiding unit, a front traction unit for tipping paper, a hot stamping unit, and a film winding unit. Ten parts, film unwinding unit and film traction unit, automatic registration unit, post-tipping paper traction unit, and tipping paper rewinding unit, among which the tipping paper unwinding unit and tipping paper traction unit are integrated into an unwinding module 1; the film rewinding unit, film unwinding unit, film traction unit, automatic registration unit, and bronzing unit are integrated into the bronzing module 2; the tipping paper rewinding unit is the rewinding module 3, and the hot stamping machine in this embodiment is becau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com