Combined coil inspection tool

A combined, coil technology, used in measuring devices, instruments, mechanical devices, etc., can solve the problems of long measurement time, short measurement time, low measurement efficiency, etc., to reduce the difficulty of production and processing, reduce errors, and reduce no operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

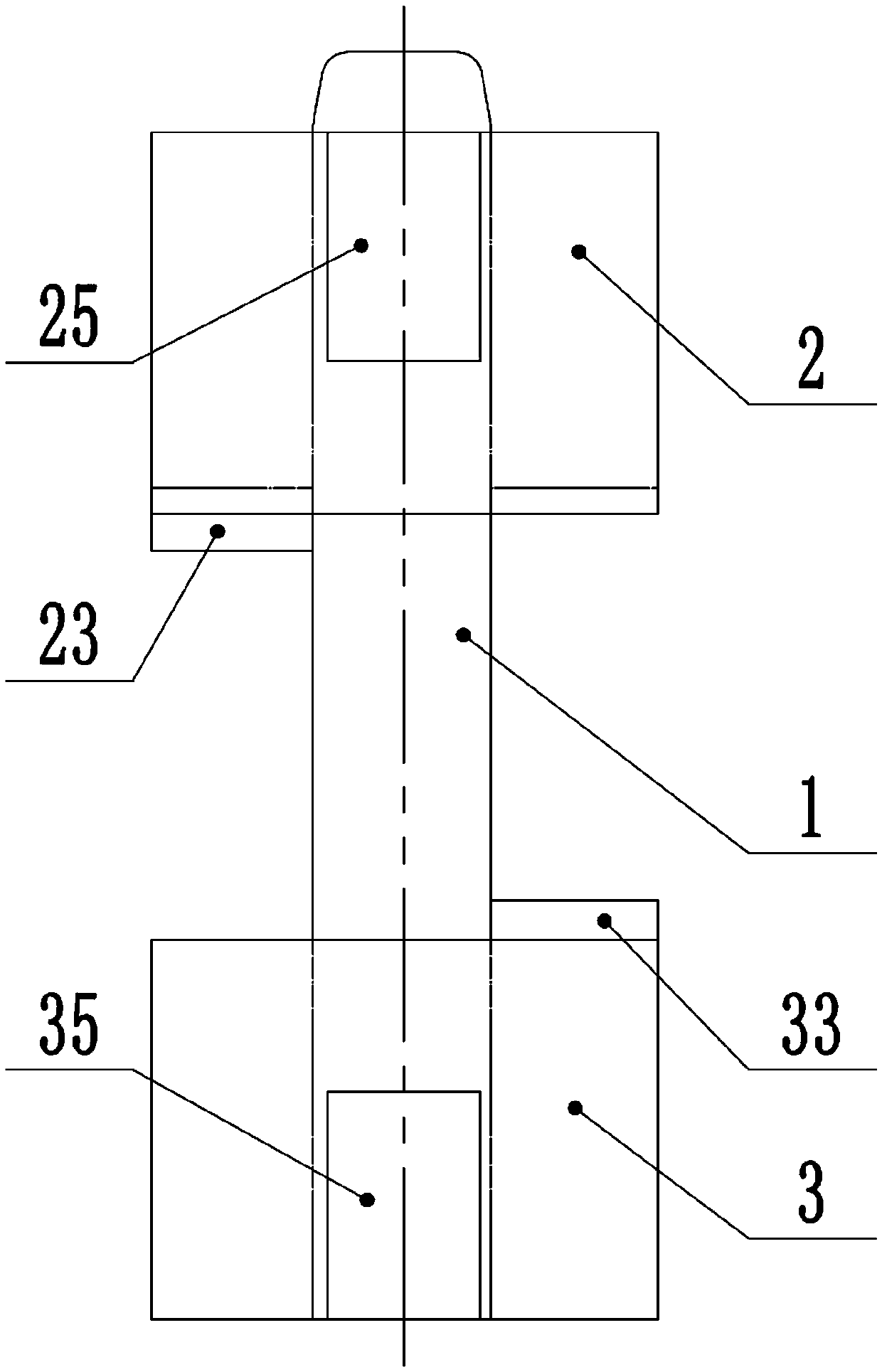

[0017] Such as Figure 1-Figure 4 As shown, the combined coil inspection tool includes a positioning shaft 1, an upper block 2 and a base 3, and the maximum outer diameter of the positioning shaft 1 is the standard size of the inner diameter of the coil.

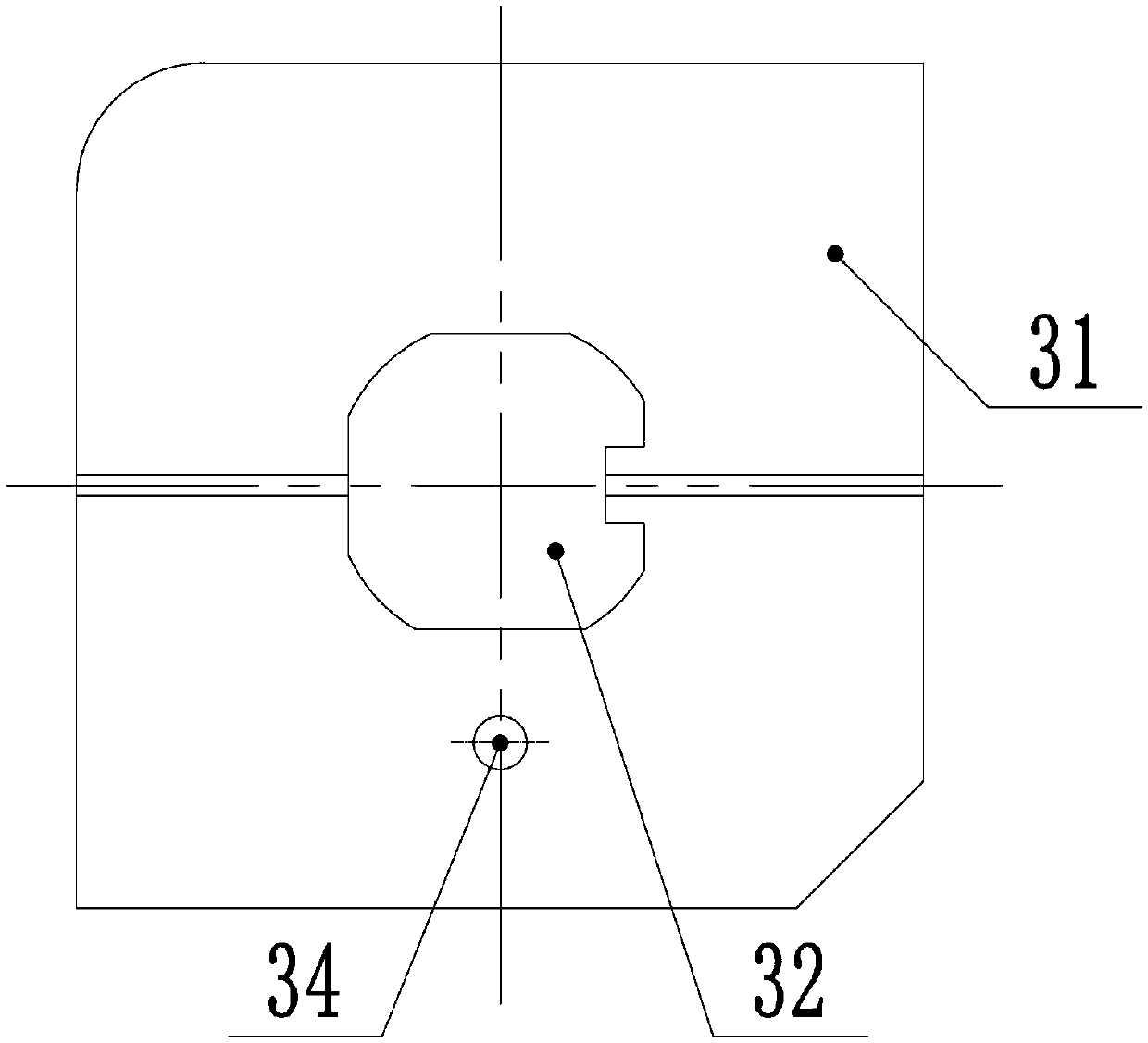

[0018] Described base 3 comprises base base body 31, and the center of base base body 31 is provided with the base slide hole 32 that is compatible with positioning shaft 1, and the upper surface of base base body 31 is provided with lower central positioning piece 33, and the base slide hole 32 side The base base body 31 is provided with a base reference size hole 34 , and the lower center height measuring groove 35 is preset on the base base body 31 at the lower part of the base reference size hole 34 .

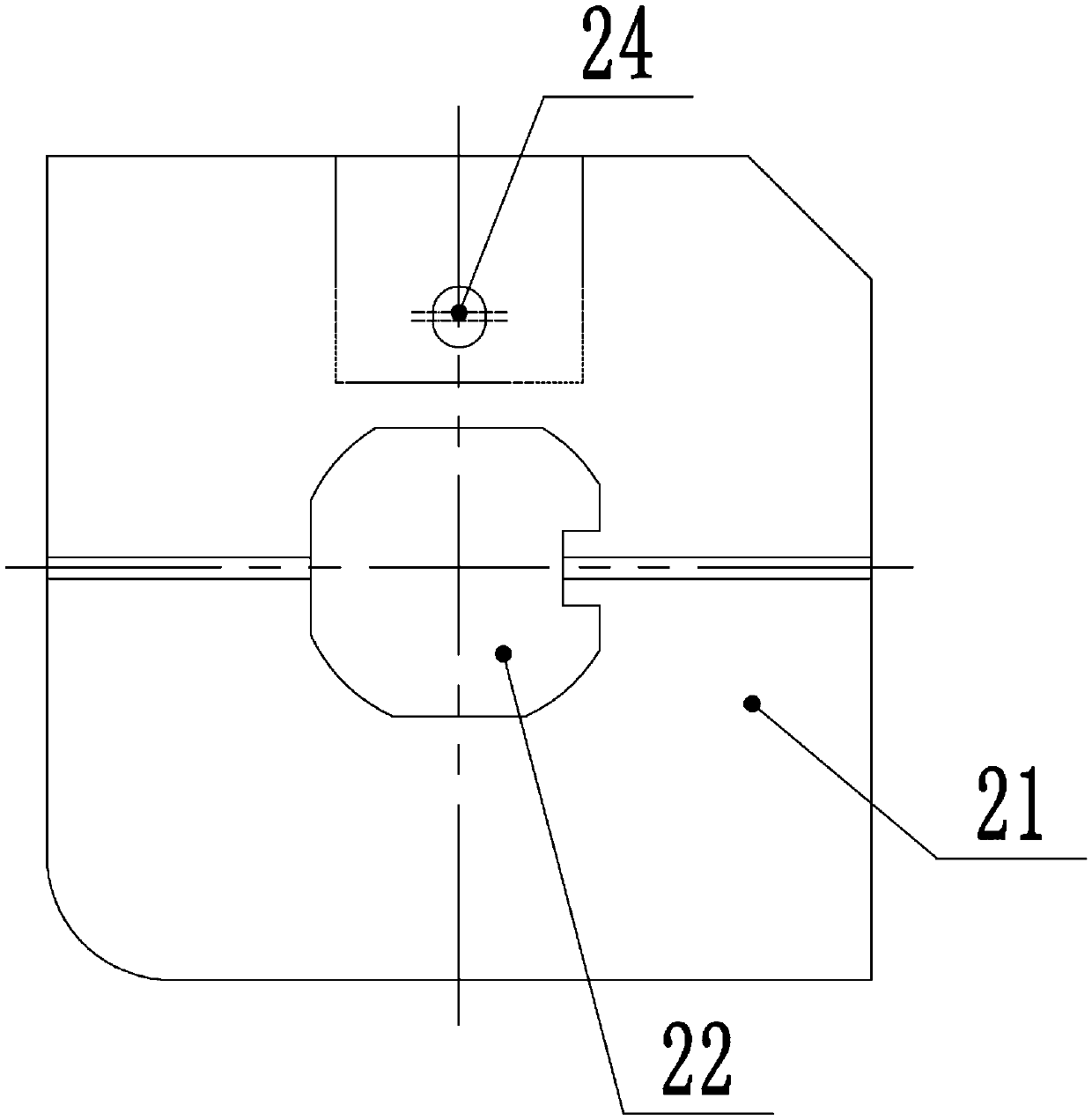

[0019] The upper block 2 includes an upper block base body 21, the center of the upper block base body 21 is provided with an upper block sliding hole 22 adapted to the positioning shaft 1, and the lower surface of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com