A method of determining a surface subsidence coefficient for coal mining under a loess gully region

A technology for determining a loess gully area and a method is applied in the field of determining the subsidence coefficient of coal seam mining in the loess gully area. Use, use effect is good, achieve convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

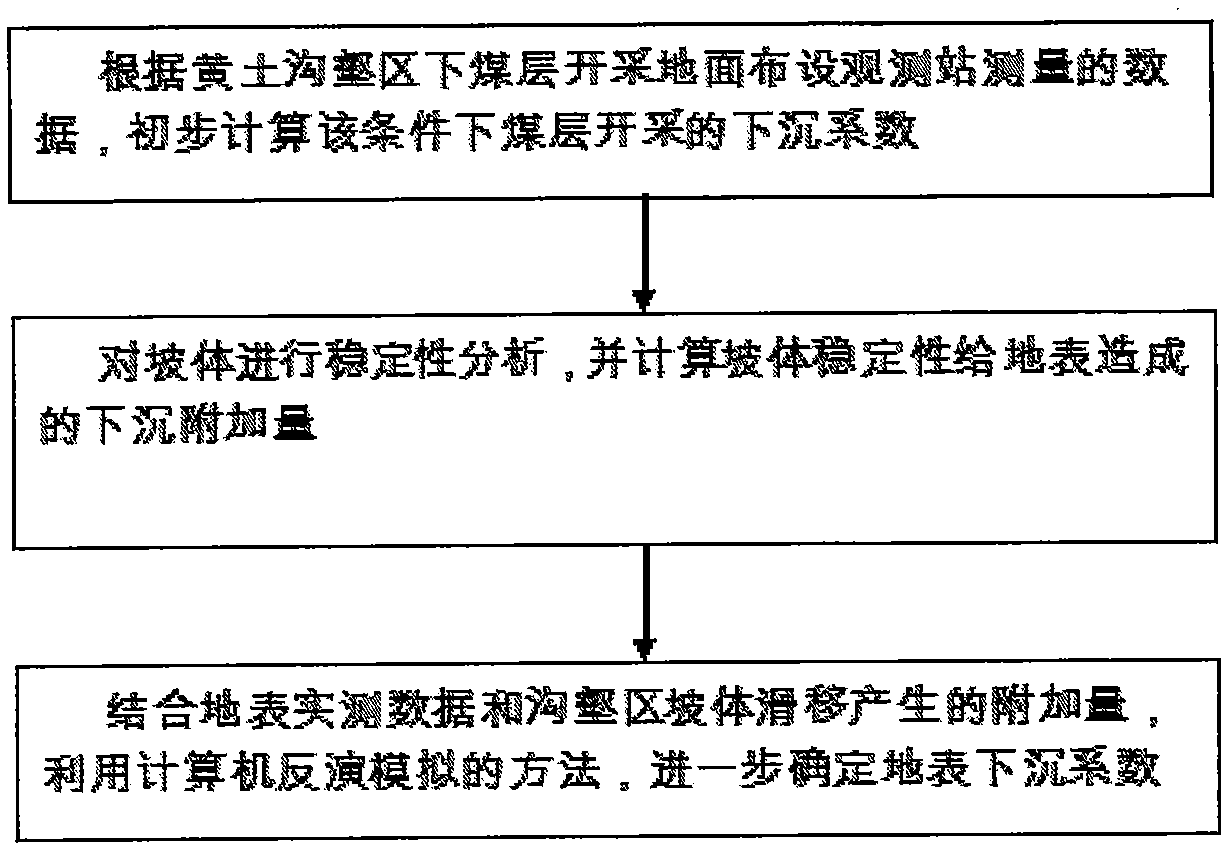

Method used

Image

Examples

Embodiment

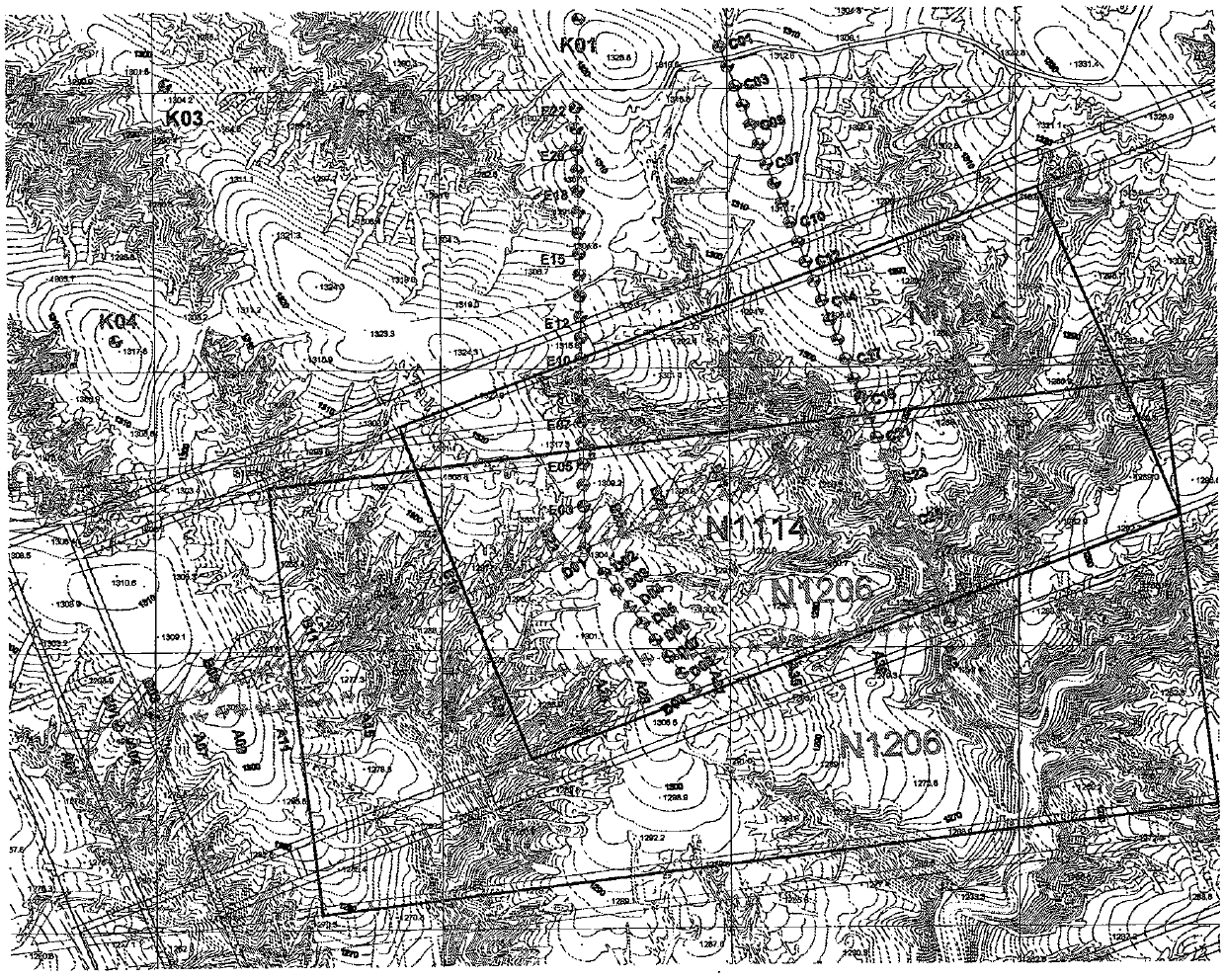

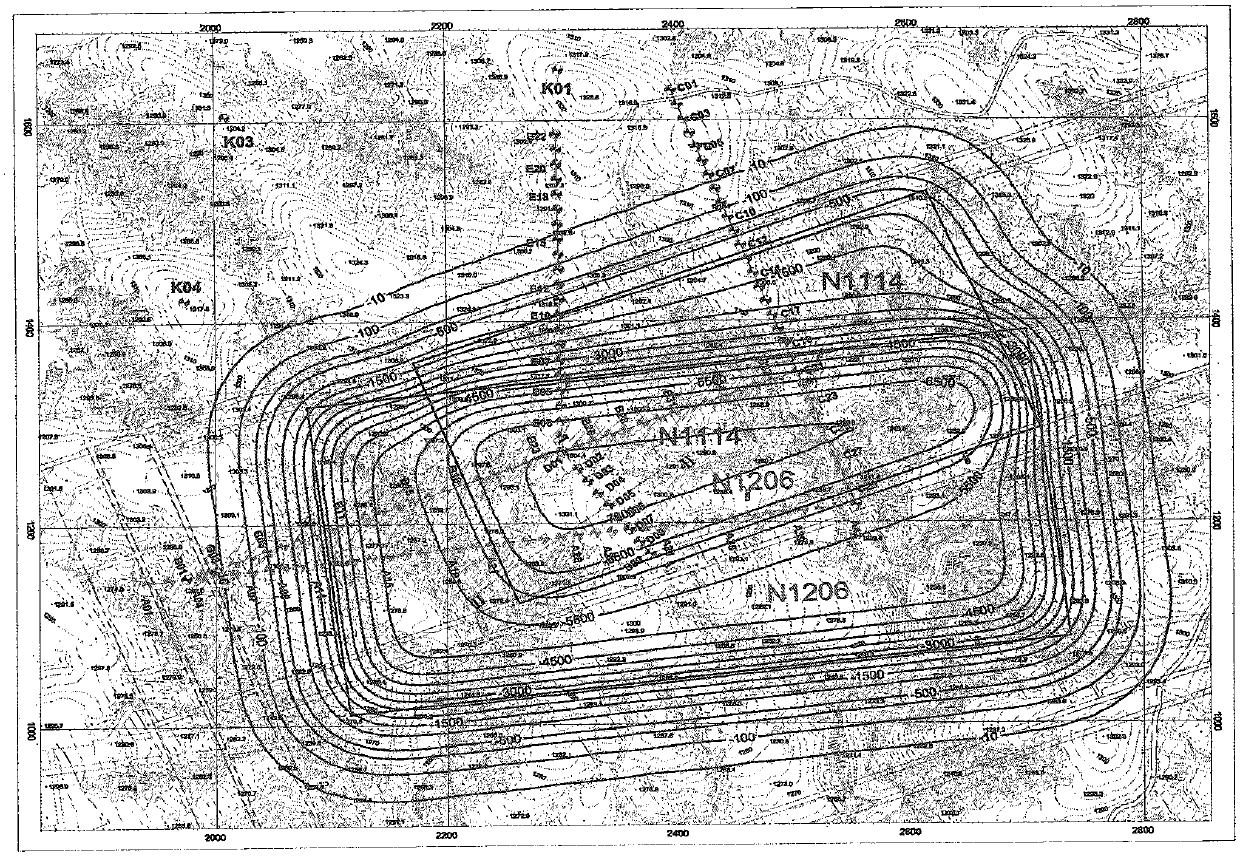

[0058] In the following, the determination of the surface subsidence coefficient after the N1114 and N1206 working faces of Ningtiaota coal mine are slanted and overlapped is used as an example to verify the technical effect of the method for determining the surface subsidence coefficient of the present invention.

[0059] Mining seam at N1114 working face of Ningtiaota coal mine is 1 -2 No. # coal seam is a near-level coal seam with an average thickness of 1.85m, simple geological structure, and an average buried depth of 123m; the mining seam at N1206 face is 2 -2 The ## coal seam is a nearly horizontal coal seam with an average thickness of 5.9m, a simple geological structure, and an average buried depth of 162m. The layout of the surface observation station is as follows figure 2 Shown.

[0060] Since the maximum subsidence value of the laid observation line is mainly located in the overlapping area, when calculating the subsidence coefficient, the mutual influence of the N1114 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com