An aerosol sampling and dehumidification method and device

An aerosol and airflow technology, applied in the field of dehumidification, can solve the problems of monitoring system safety without more consideration, affecting the share of collection, changing chemistry, etc., to overcome the serious problem of aerosol loss, guarantee lifespan, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

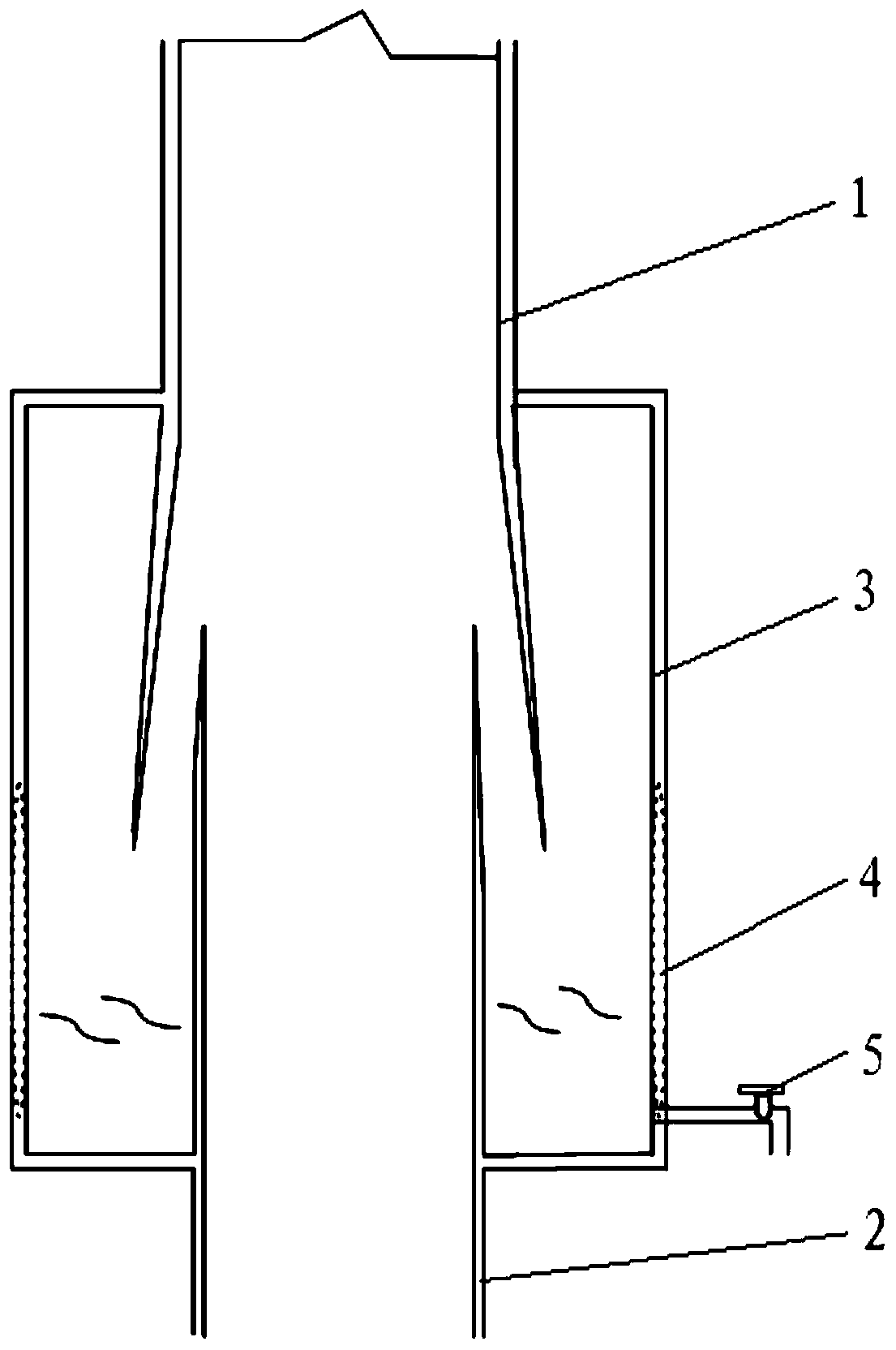

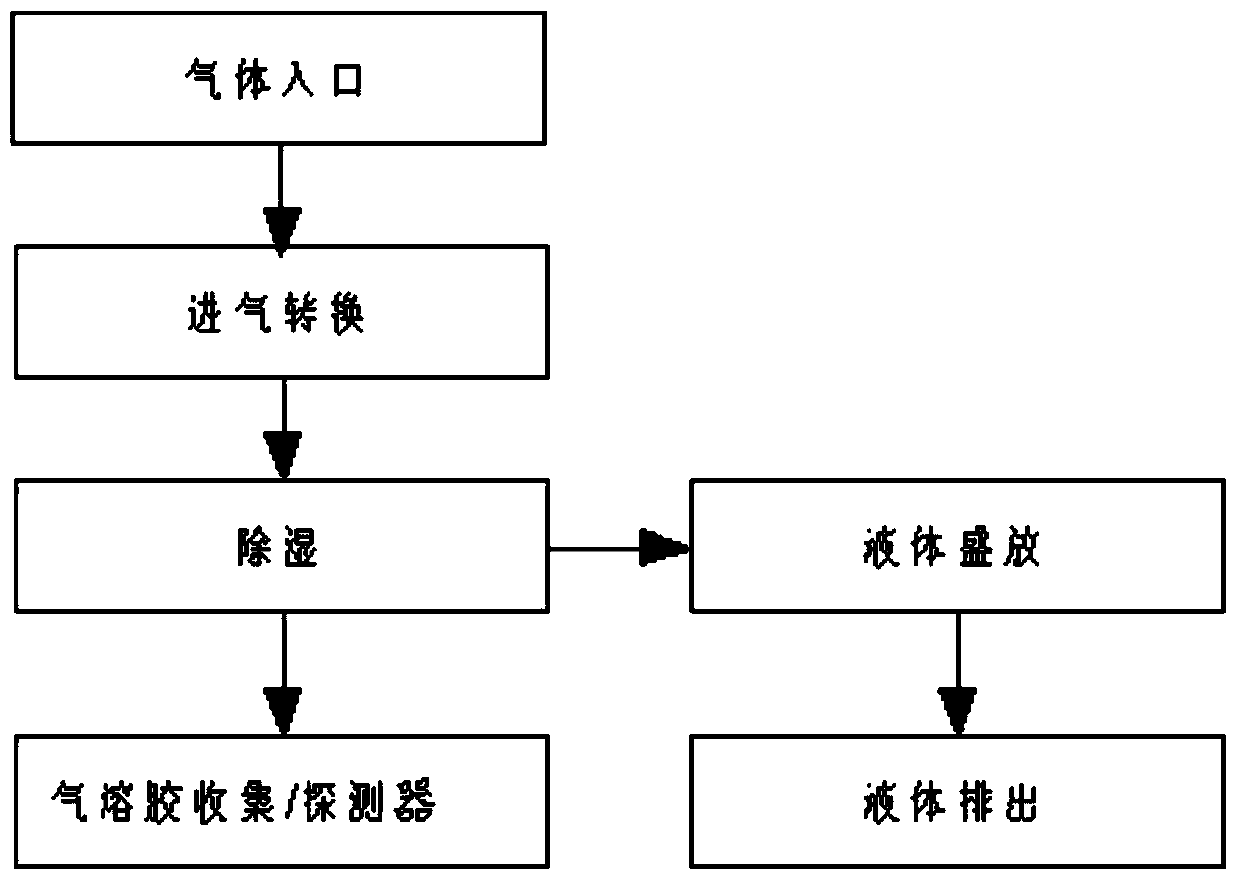

[0033] like figure 1 Shown is the aerosol sampling and dehumidification device provided by the present invention. The dehumidification device is not only suitable for dehumidification of radioactive aerosol sampling, but also suitable for dehumidification of non-radioactive aerosol or PM sampling. The dehumidification device is arranged on the gas transmission pipeline at the front end of the sampling or detection system, which includes an upper elbow 1 , a lower elbow 2 and a liquid container 3 . Wherein, the lower bend pipe 2 is arranged below the upper bend pipe 1, preferably directly below the upper bend pipe. The opening angle of the splayed structure of the elbow, the lower part of the upper elbow is sleeved on the upper part of the lower elbow, and there is a gap in the sleeve part; the lower part of the upper el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com