Circuit board testing apparatus and circuit board testing method

A substrate inspection and substrate technology, which is applied in measurement devices, electronic circuit testing, instruments, etc., can solve problems such as errors, and achieve excellent accuracy, reliability and easy confirmation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The best mode for carrying out the present invention will be described.

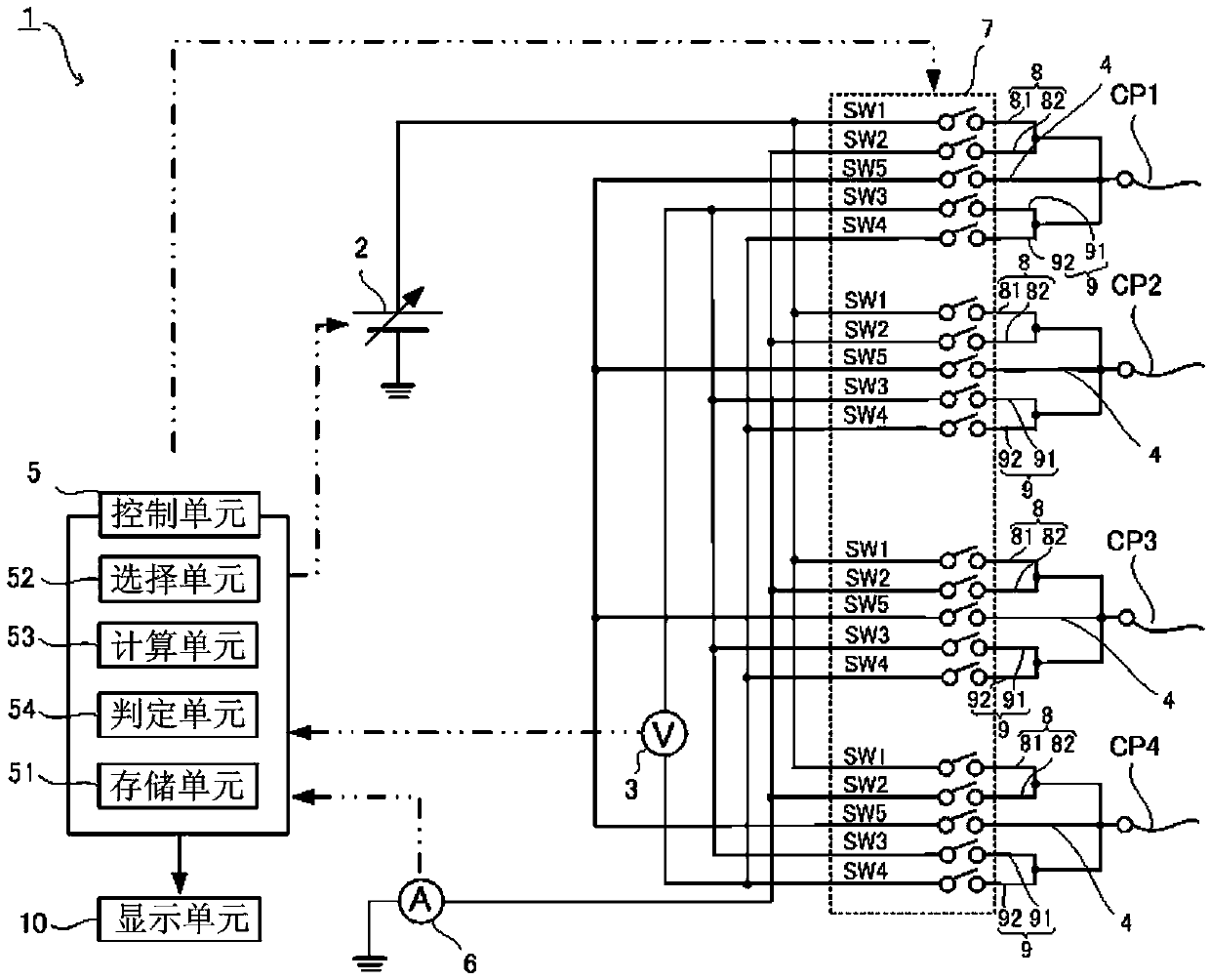

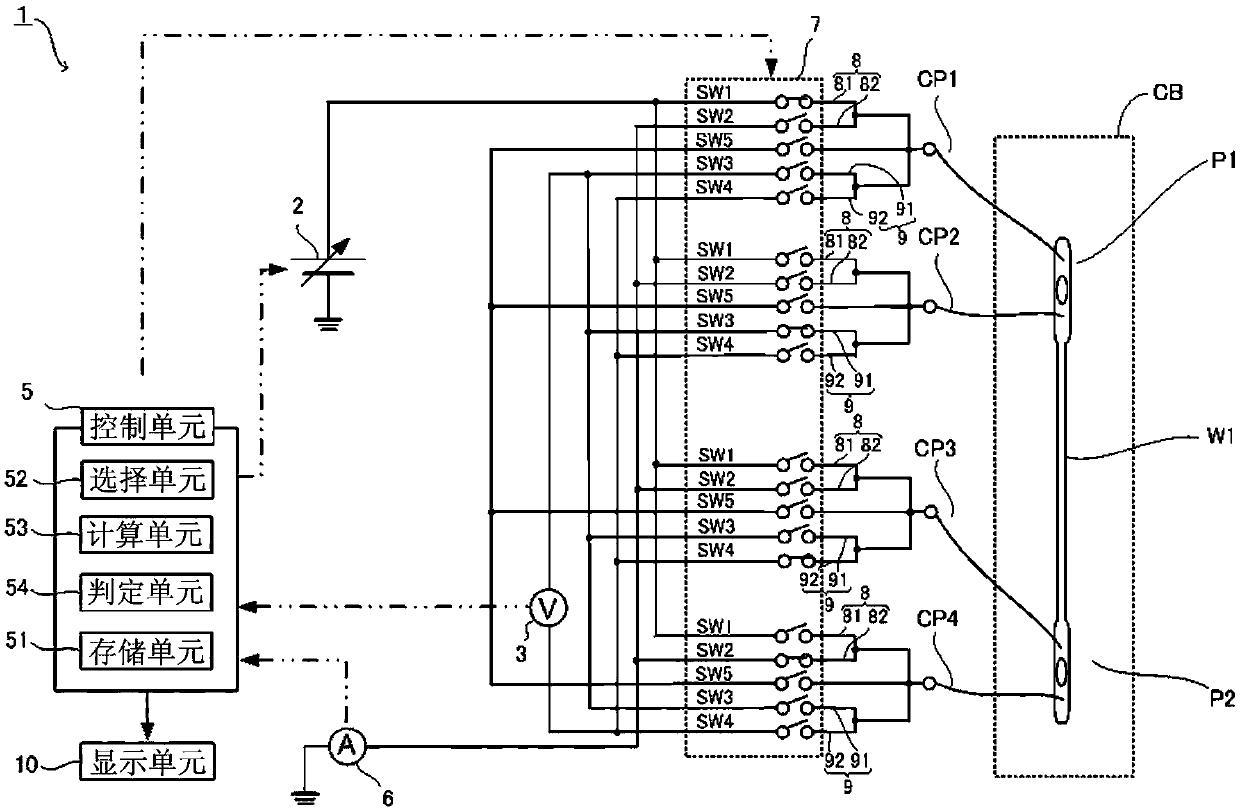

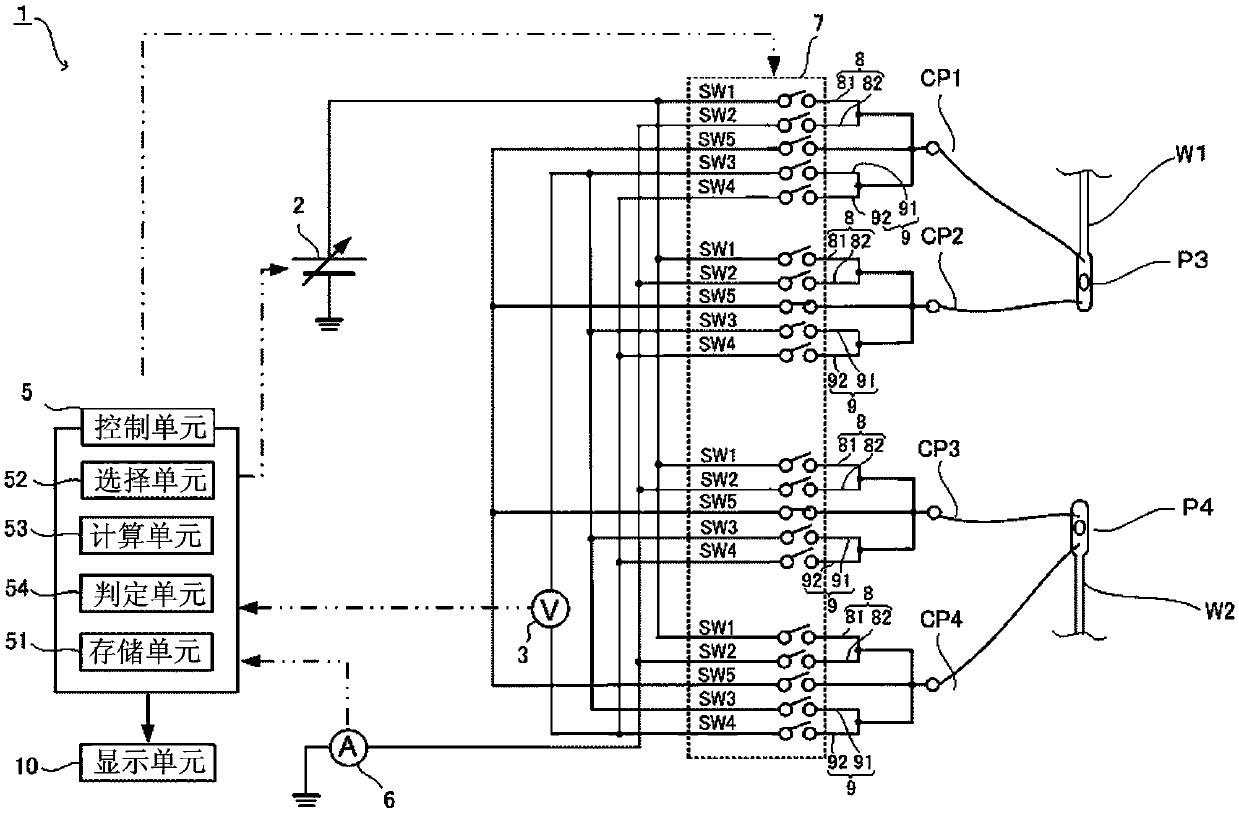

[0050] figure 1 It is a schematic structural diagram of the board|substrate inspection apparatus of this invention.

[0051] The substrate inspection device 1 of the present invention has a power supply unit 2, a detection unit 3, a connection terminal 4, a control unit 5, a storage unit 51, a selection unit 52, a calculation unit 53, a determination unit 54, a current detection unit 6, a switching unit 7, a power Terminal 8, detection terminal 9 and display unit 10.

[0052] In this substrate inspection apparatus 1 , contacts (contact probes) CP are used in order to make conductive contact with inspection points set on a plurality of wirings (between inspection points) Rx formed on the substrate. Through this contact CP, a predetermined potential and / or current can be applied to a predetermined inspection point, or an electrical characteristic (electrical signal) can be detected from a predeter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap