Converter valve simulation platform and realization method thereof

A technology of simulation platform and implementation method, which is applied in the field of power electronics, can solve problems such as commutation failure, and achieve the effects of ensuring real-time performance, accurate and reliable simulation, and simple control logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

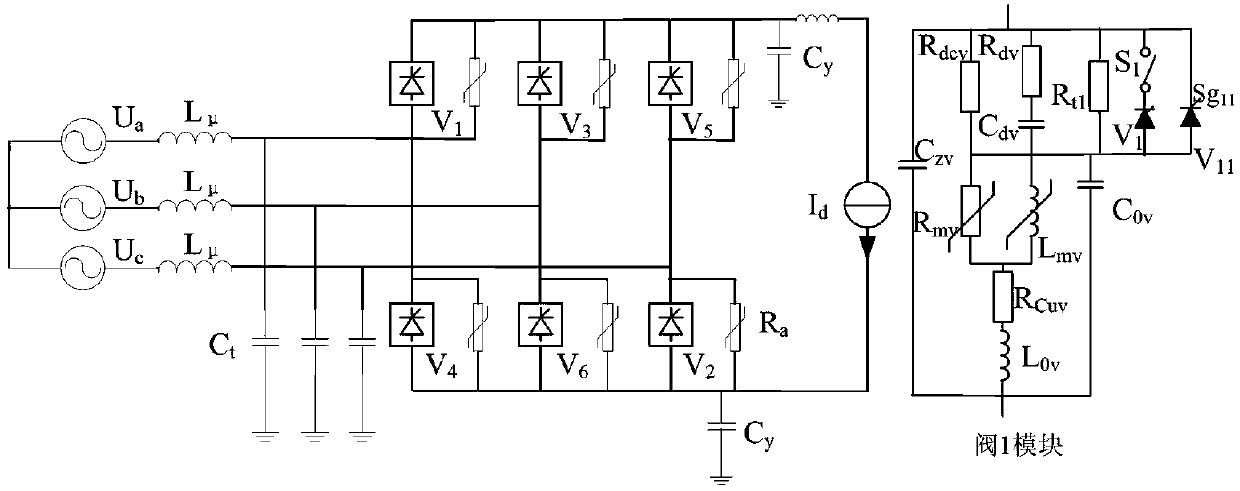

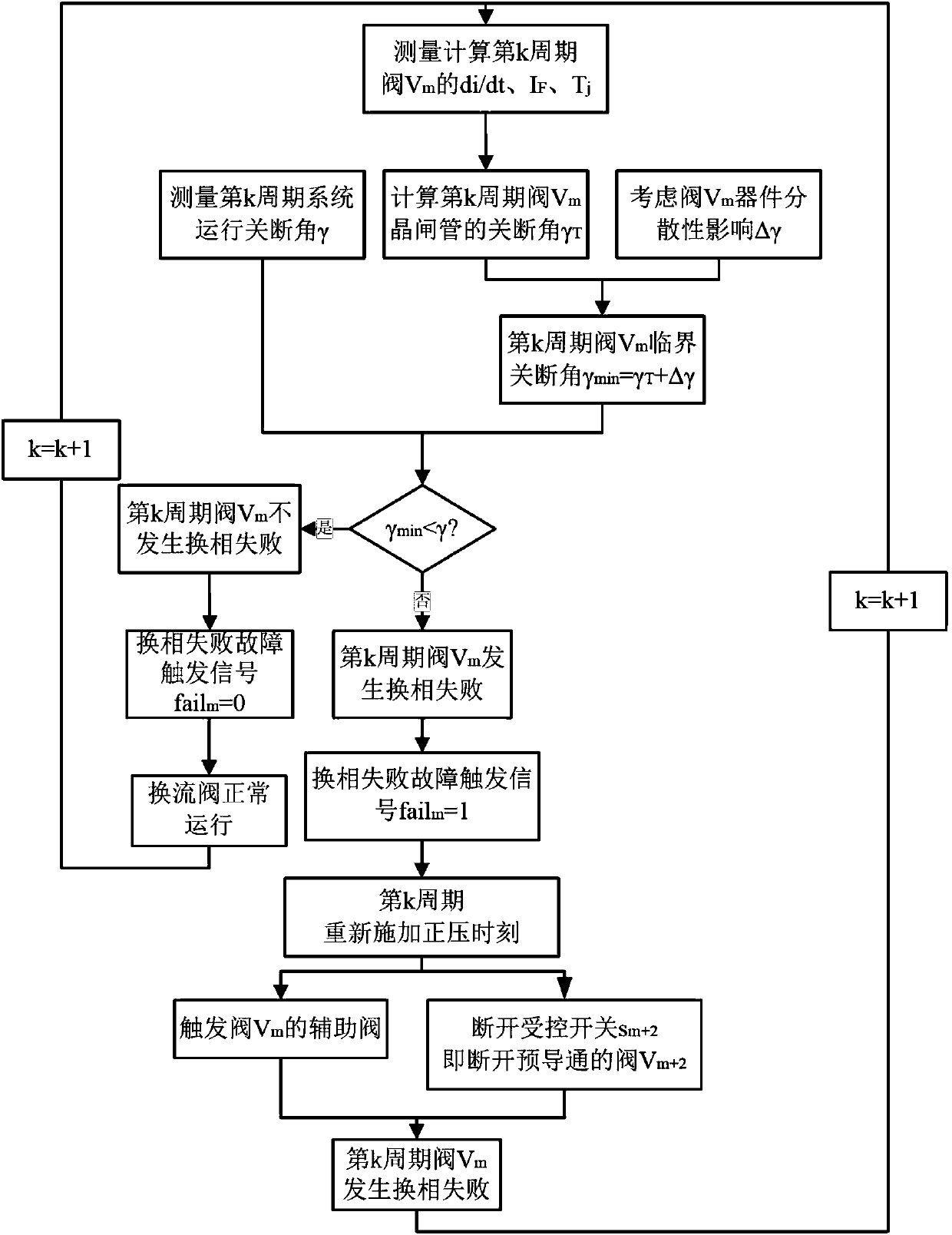

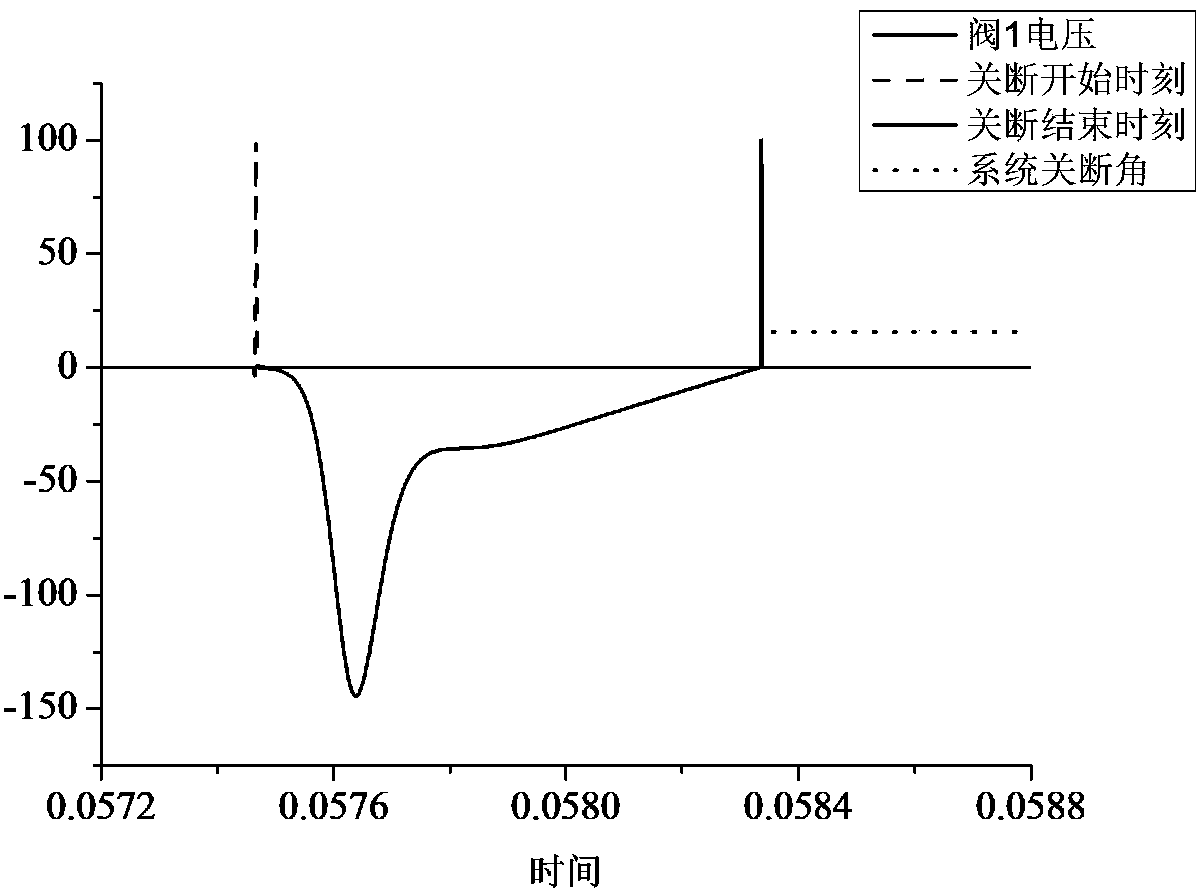

[0042] The invention is a simulation platform for analyzing the influence of the internal operating parameters and electrical parameters of the converter valve on the phase commutation failure. The commutation failure of converter valve is one of the most common faults in HVDC transmission system, which will lead to many adverse consequences, directly related to the safety of equipment and system. The essence of the commutation failure of the converter valve is that the operating cut-off angle is smaller than the critical cut-off angle of the converter valve, and both are affected by various factors inside the valve. The present invention measures and calculates the internal sub-factors of the converter valve that affect the shut-off process in real time, and obtains the real-time critical shut-off angle of the valve acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com