PTZ correction method

A correction method and cloud platform technology, applied in image data processing, instruments, calculations, etc., can solve the problems of increased cost and low correction accuracy, and achieve the effect of improving alignment accuracy and reducing target deviation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

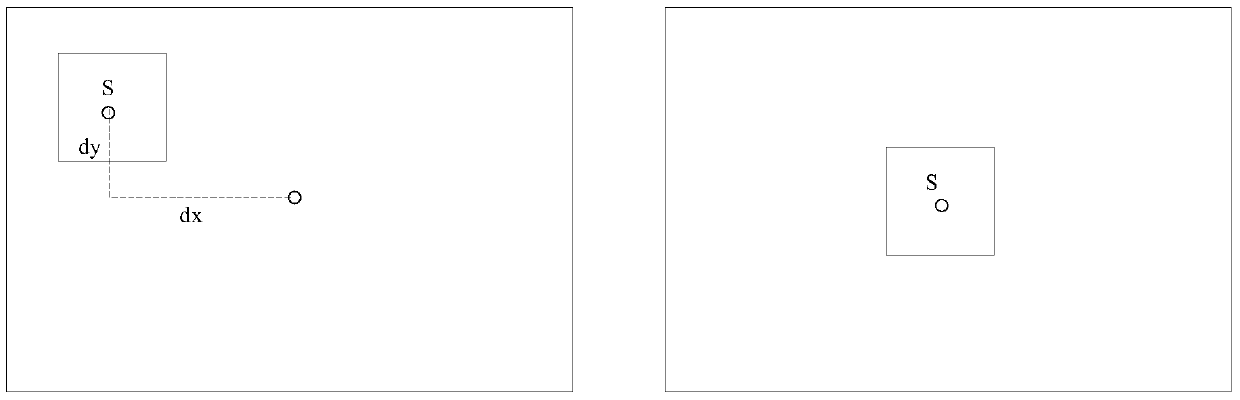

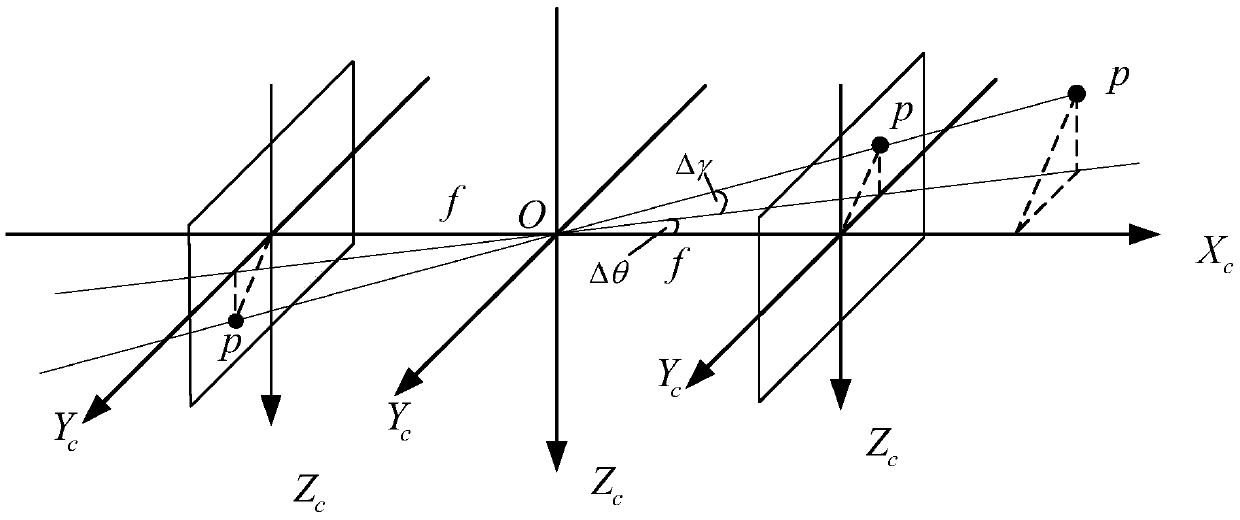

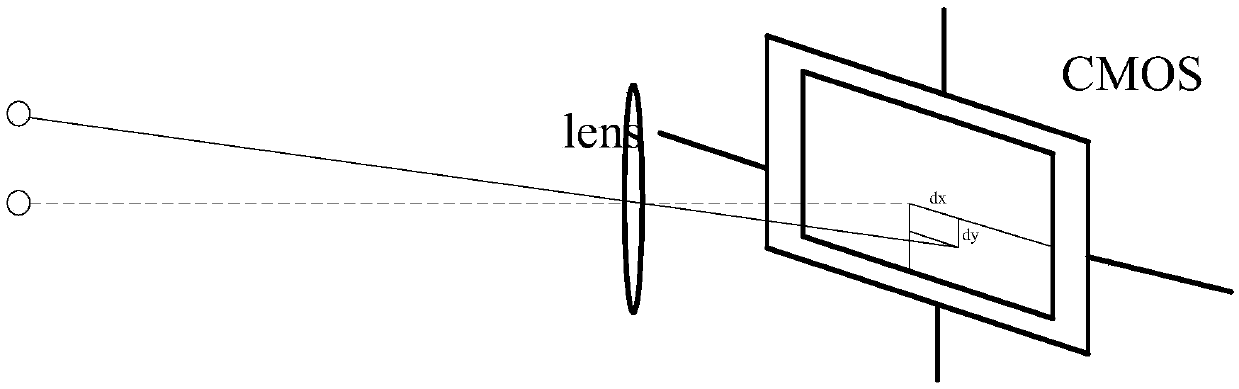

[0026] The present invention uses machine vision technology to identify the target point, by collecting a picture at a certain preset position as a template picture, and recording the azimuth, pitch angle and camera zoom factor at this time; modeling the template picture, using the template The center point of the picture is taken as the center to extract the outline of the target object; set the pan / tilt and camera to collect the picture at the preset position when the template picture is collected, compare the collected picture with the template picture, and calculate the offset pixel of the target object ; Calculate the gimbal offset angle according to the obtained offset pixels, and add the obtained gimbal offset angle to the gimbal preset position to obtain the corrected absolute angle. The following takes the pan-tilt calibration proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com