Hard disk demagnetizing module, demagnetizing and smashing integrated machine and hard disk demagnetizing method

A hard disk disc and degaussing technology, which is applied in the field of hard disk disc degaussing module, degaussing and pulverizing machine and hard disk degaussing, can solve the problems of large cross-sectional area of coil cavity, increase of manufacturing cost, increase of discharge voltage of energy storage capacitor capacity, etc. , to achieve the effect of ensuring degaussing effect and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

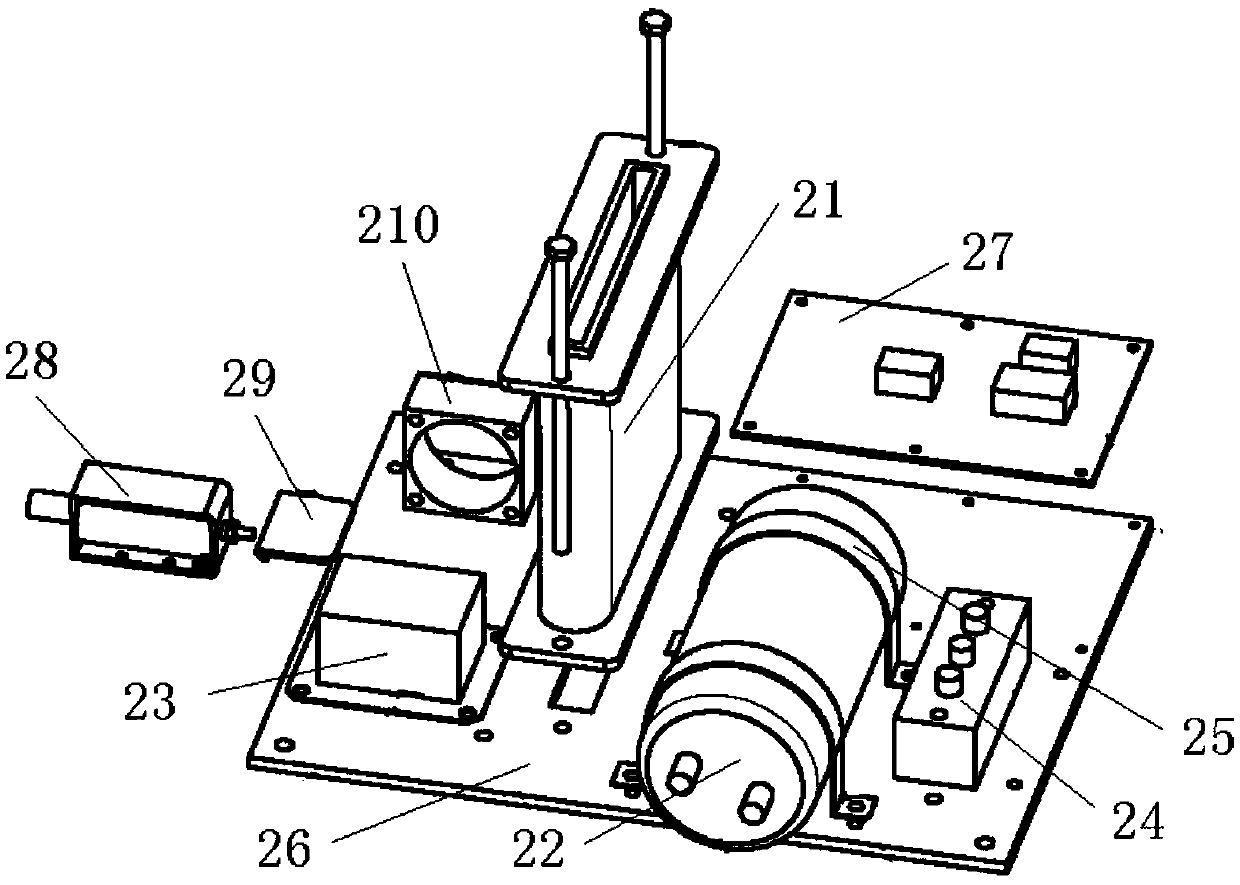

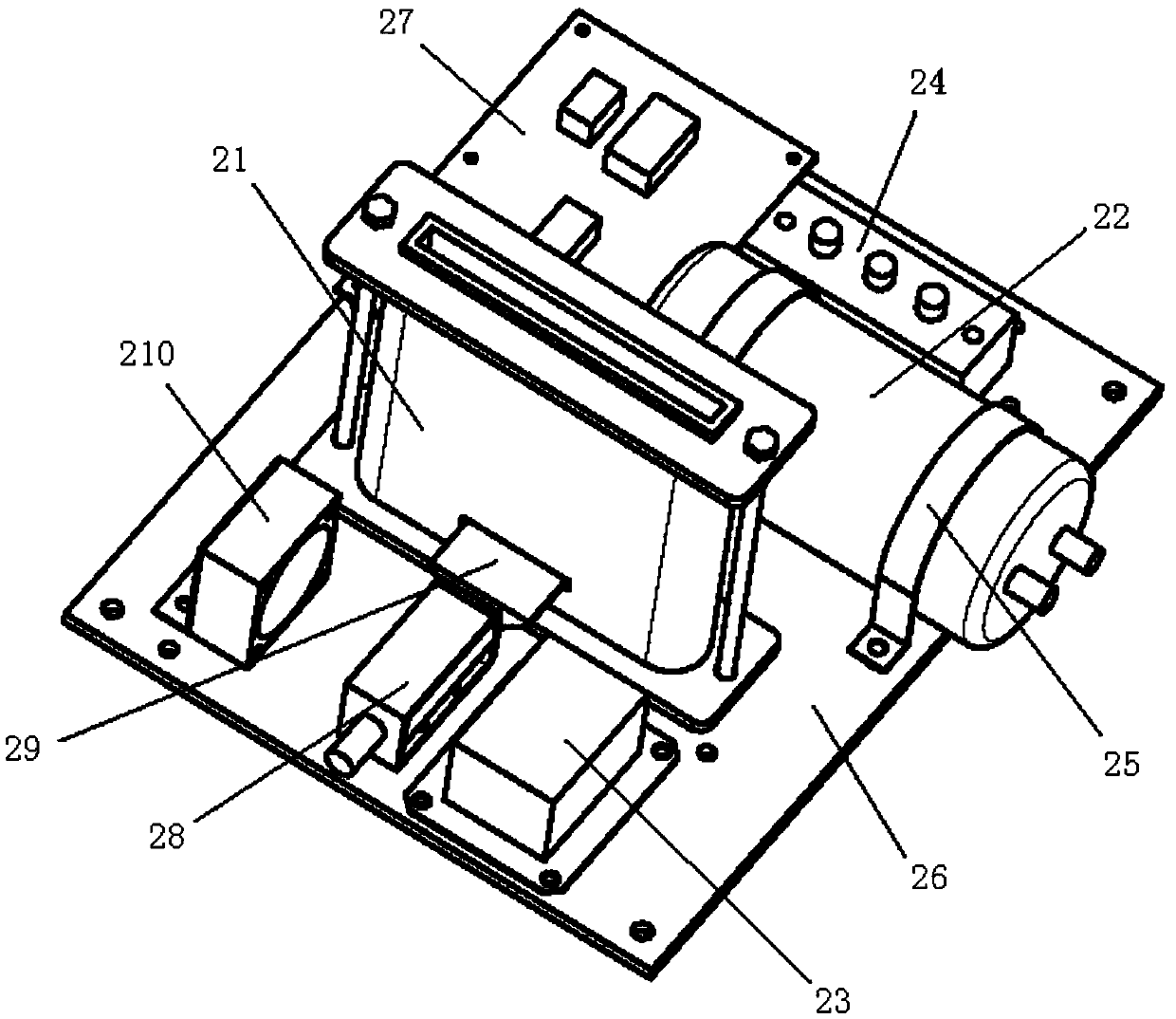

[0037] figure 1 It is a schematic diagram of dismantling the three-dimensional structure of the hard disk disc degaussing module in Embodiment 1 of the present invention; figure 2 It is a structural schematic view of the hard disk degaussing module in Embodiment 1 of the present invention viewed from another angle. In the figure, the meanings of each reference mark are as follows: 21. Degaussing coil; 22. Energy storage capacitor; 23. Transformer; 24. SCR diode; 25. Energy storage capacitor strap; 26. Degaussing module bottom plate; 27. Degaussing circuit board; 28. Degaussing discharge electromagnet; 29. Disk block; 210. Cooling fan.

[0038] A hard disk degaussing module, comprising a feeding device 1 and a hard disk degaussing module 2, the feeding device 1 is arranged above the hard disk degaussing module 2, the feeding device 1 has a feeding inlet 2, and the hard disk is degaussed The module 2 has a degaussing coil 21, the degaussing coil 21 has a skeleton cavity, th...

Embodiment 2

[0061] The difference between this embodiment and Embodiment 1 is that the degaussing coil is made of yarn-wrapped copper flat wire or yarn-wrapped aluminum flat wire, and the number of winding layers of yarn-wrapped copper wire or yarn-wrapped aluminum wire can be 4-6 layers . Preferably, when the yarn-wrapped copper flat wire is selected, the cross-sectional size of the yarn-wrapped copper flat wire is 2×6 mm, the number of layers of the yarn-wrapped copper flat wire is 4 layers, and the number of turns is 80 turns ± 2 turns; when the yarn-wrapped copper flat wire is selected For aluminum flat wires, the cross-sectional size of yarn-wrapped aluminum flat wires is 3×7mm. The number of layers of yarn-wrapped aluminum flat wire is 4 layers, and the number of turns is 62 turns ± 2 turns. The SCR diode can be 1600V / 200A or 1600V / 50A SCR diode, the transformer can be 50W / 400V transformer, the degaussing voltage is 370V-380V, and the energy storage capacitor can be 10000μF / 400V ca...

Embodiment 3

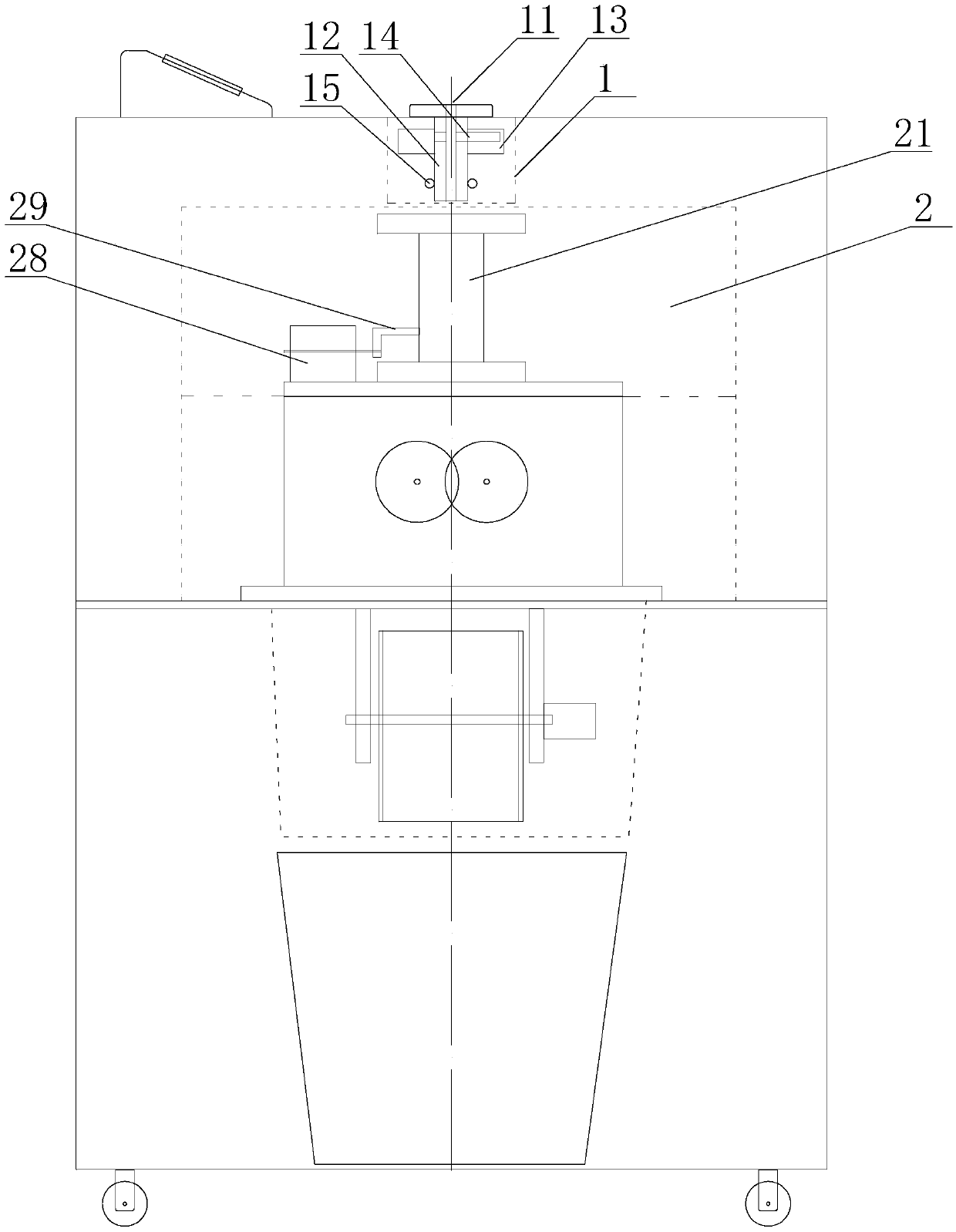

[0088] image 3 It is a schematic structural view of the degaussing and pulverizing all-in-one machine according to Embodiment 3 of the present invention; in the figure, the meanings of the newly appearing reference numerals are as follows:

[0089] 1. Feeding device; 11. Feeding inlet; 12. Feeding cylinder; 13. Feeding electromagnet; 14. Feeding block; 15. Feeding sensor; 2. Hard disk degaussing module; 3. Crushing module ;

[0090] An integrated degaussing and pulverizing machine, comprising a feeding device 1 and a hard disk degaussing module 2, the feeding device 1 is arranged above the hard disk degaussing module 2, and the crushing module 3 is arranged below the hard disk degaussing module 2.

[0091] The feeding device 1 includes a feeding cylinder 12 that penetrates up and down. The upper part of the feeding cylinder 12 is provided with a feeding stopper 14. The feeding stopper 14 is connected with the feeding electromagnet 13, and the feeding electromagnet 13 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com