sinking plate cooling led bracket

A technology of LED brackets and sinking boards, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of difficult packaging of LED lamps, inability to dissipate heat of LED chips in time, poor thermal conductivity of insulating materials, etc., and achieve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

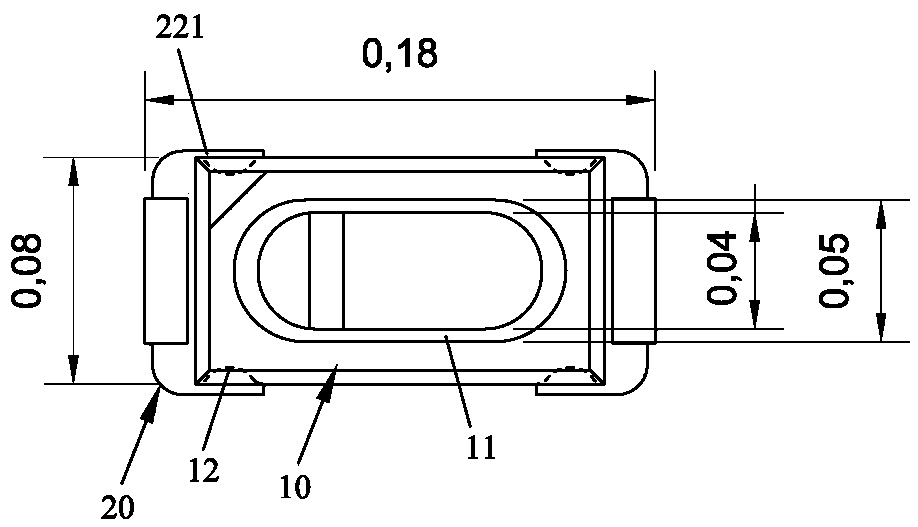

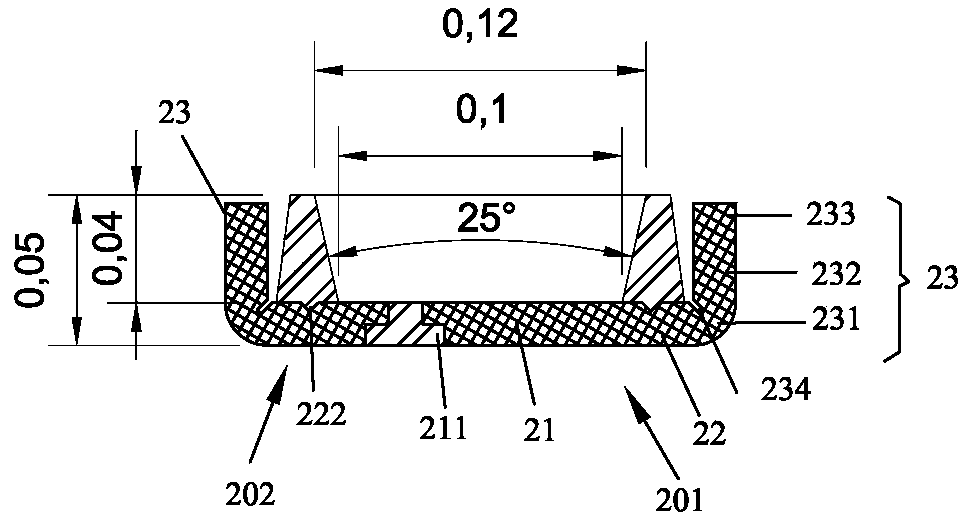

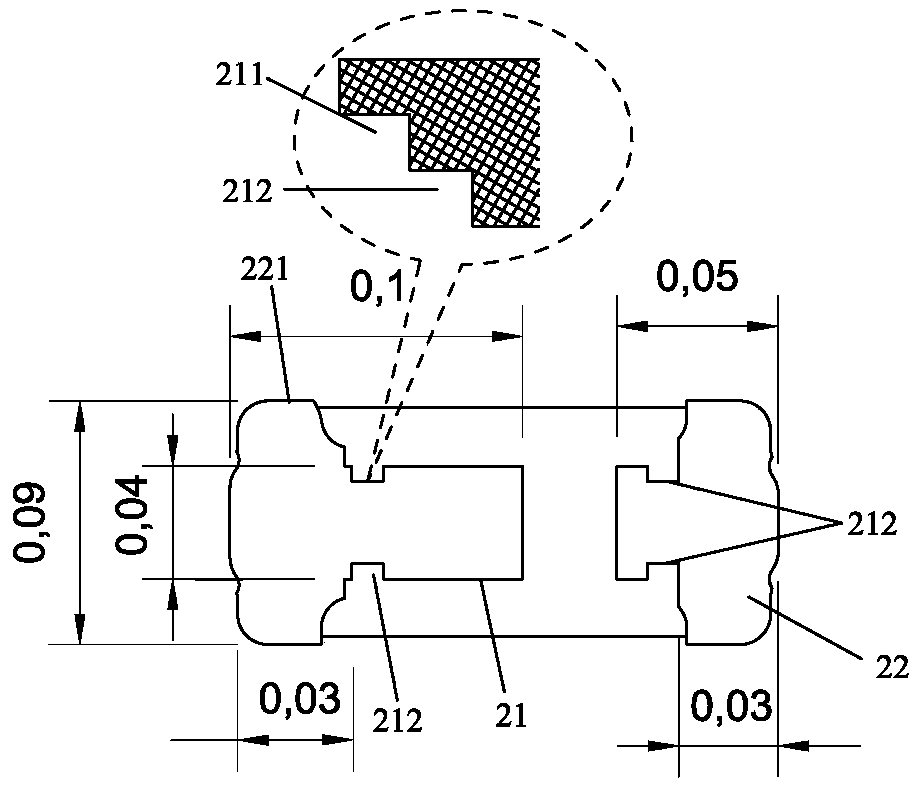

[0036] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the preferred embodiment of the present invention, which is a sunken plate heat dissipation LED bracket, including a plastic main body 10 and two conductive terminals 20, the two conductive terminals 20 are composed of a positive terminal 201 and a The negative terminal 202 is composed of two conductive terminals 20 and the plastic main body 10 are integrally molded.

[0037] Wherein, the plastic body 10 is in the shape of a cuboid, and its length, width and height are 0.18mm*0.08mm*0.05mm, respectively. The top of the plastic body 10 is recessed with a reflective cup 11. The reflective cup 11 is in the shape of a racetrack. mm*0.05mm, the depth of the reflective cup 11 is 0.04mm, and the angle formed by the left and right side walls of the reflective cup 11 is 25°. Such size design makes the plastic main body 10 of fixed size have a larger reflective cup 11, which can be installed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com