A kind of heterojunction laser and preparation method thereof

A heterojunction and laser technology, applied in lasers, semiconductor lasers, phonon exciters, etc., can solve the problems of large temperature influence, poor directivity, monochromaticity and coherence, large beam divergence angle, etc. Lattice matching, particle number inversion, and simple process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

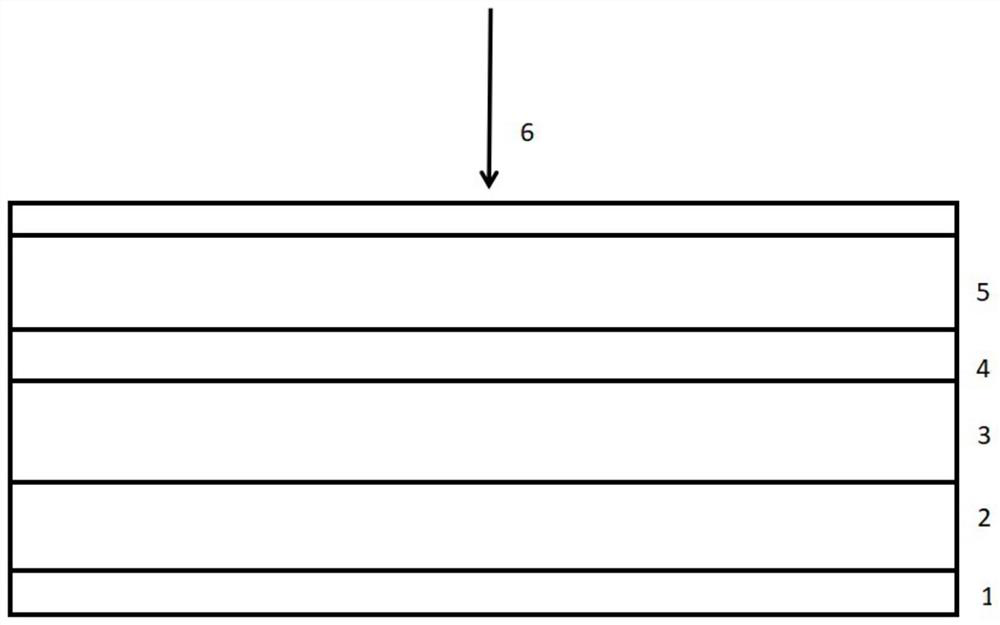

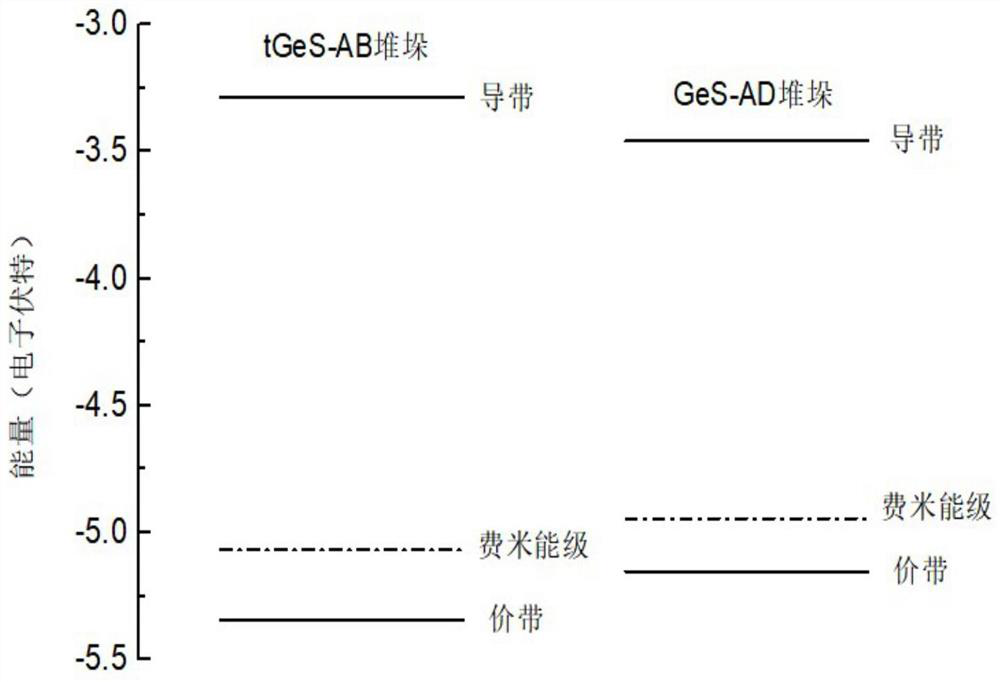

[0033] The preparation method of the heterojunction semiconductor laser of the present invention comprises the following steps:

[0034] a. Substrate preparation

[0035] In this patent, n-Si (111) sheet is used as the substrate, and the Si sheet is soaked in HF to remove the silicon dioxide on the surface, and then the Si sheet is cleaned several times with propanol, ethanol and deionized water to remove foreign matter on the surface of the silicon wafer. Dry the Si wafer with nitrogen and put it into a vacuum quartz tube for deposition treatment; heat the quartz tube to 300°C for 10-15min to remove the water vapor on the surface of the wafer;

[0036] b. GeS thin film preparation

[0037] 0.2g of germanium chloride dioxane complex, 0.4g of thiourea, and 20ml of oleamide OLA were added to a 25ml three-necked flask respectively, and were slightly magnetically stirred in the air; the stirred liquid mixture was ultrasonically treated for 5min, Remove the air in the oleylamine; t...

Embodiment

[0045] a. Substrate preparation

[0046] In this patent, n-Si (111) sheet is used as the substrate, and the Si sheet is soaked in HF to remove the silicon dioxide on the surface, and then the Si sheet is cleaned several times with propanol, ethanol and deionized water to remove the foreign matter on the surface of the silicon wafer. Dry the Si wafer with nitrogen and put it into a vacuum quartz tube for deposition treatment; heat the quartz tube to 300°C for 10-15min to remove the water vapor on the surface of the wafer;

[0047] b. GeS thin film preparation

[0048] 0.2g of germanium chloride dioxane complex, 0.4g of thiourea, and 20ml of oleamide OLA were added to a 25ml three-necked flask respectively, and were slightly magnetically stirred in the air; the stirred liquid mixture was ultrasonically treated for 5min, Remove the air in the oleylamine; then connect the three-necked flask to the Schlenk line, evacuate for 30 minutes to remove moisture and oxygen; pass nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com