Elastomer roller

A body roll and elastic technology, applied in the field of elastic body rolls, can solve the problems such as the difficulty of accurate transfer of belt-shaped parts, and achieve the effect of stable transfer and guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

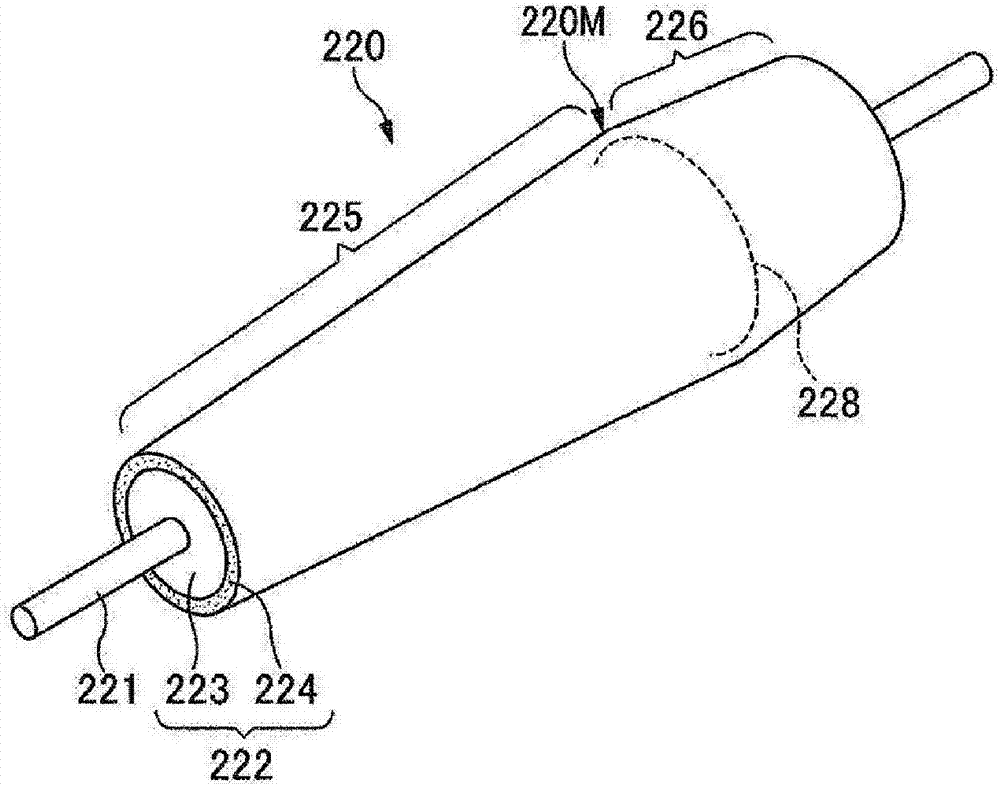

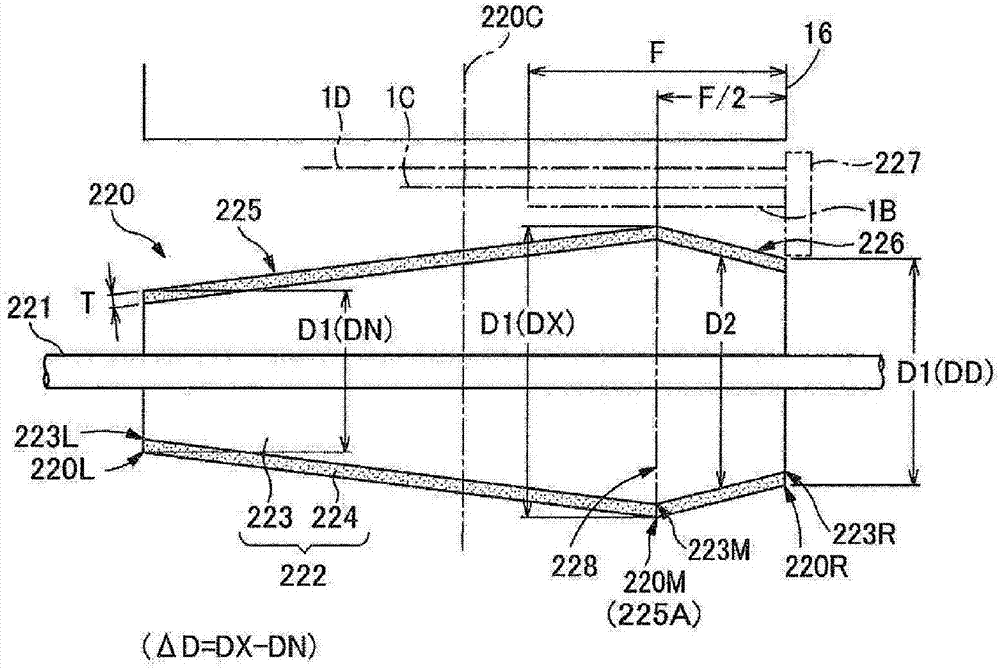

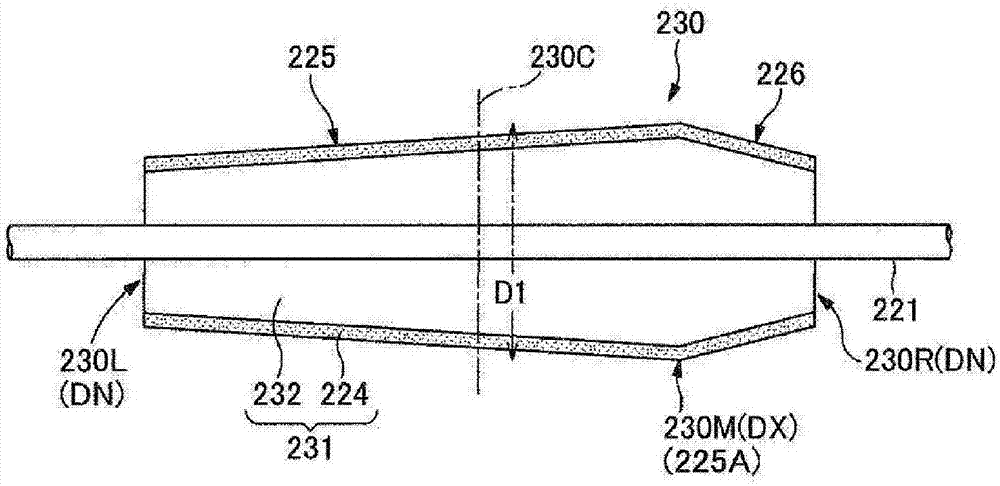

[0067] Next, to combine the elastic body roll of the first embodiment of the present invention with the above-mentioned platen roll 17 ( Figure 14 ) is configured as the platen roller 220 (elastic body roller for labels) in the thermal printer 8 as an example based on figure 1 as well as figure 2 Be explained. But yes with Figure 13 as well as Figure 14 The same parts are given the same reference numerals, and their detailed descriptions are omitted. figure 1 is a perspective view of the platen roller 220, figure 2 is an axial sectional view of the platen roller 220, from the thermal printer 8 ( Figure 14 ) etc. in the thermal print head 16 and platen roller 220 ( figure 2 ) is a diagram viewed in the feeding direction of the linerless label 1 . The platen roller 220 has a roller shaft 221 and an elastic member 222 mounted around the roller shaft 221 so as to be integrally rotatable, and enables labels such as the aforementioned linerless label 1, Figure 13 ) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com