Vehicle body front portion structure, and vehicle body assembly method

A technology for the front part of the body and the structure, which is applied to the connection between the superstructure sub-assemblies, the superstructure, and vehicle parts, etc. The effect of simplifying the assembly process, reducing the number of parts, and securing the joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0046] refer to Figure 1 to Figure 3 One embodiment of the present invention will be described in detail. In the description, the same reference numerals are assigned to the same elements, and overlapping descriptions are omitted. In addition, when explaining a direction, it demonstrates based on the front, back, left, and right getting up and down seen from the driver of a vehicle. In addition, the vehicle width direction and the left-right direction are synonymous.

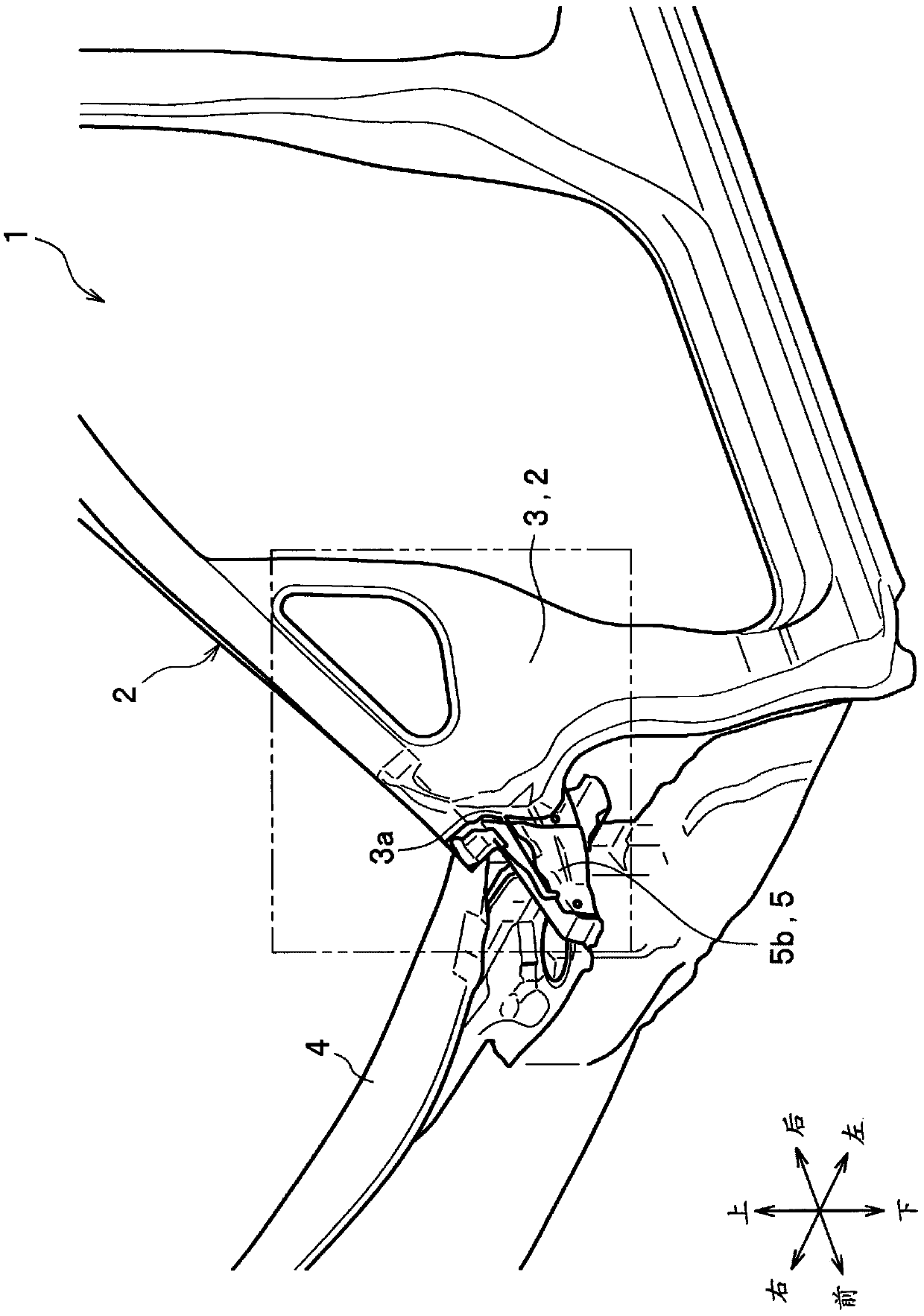

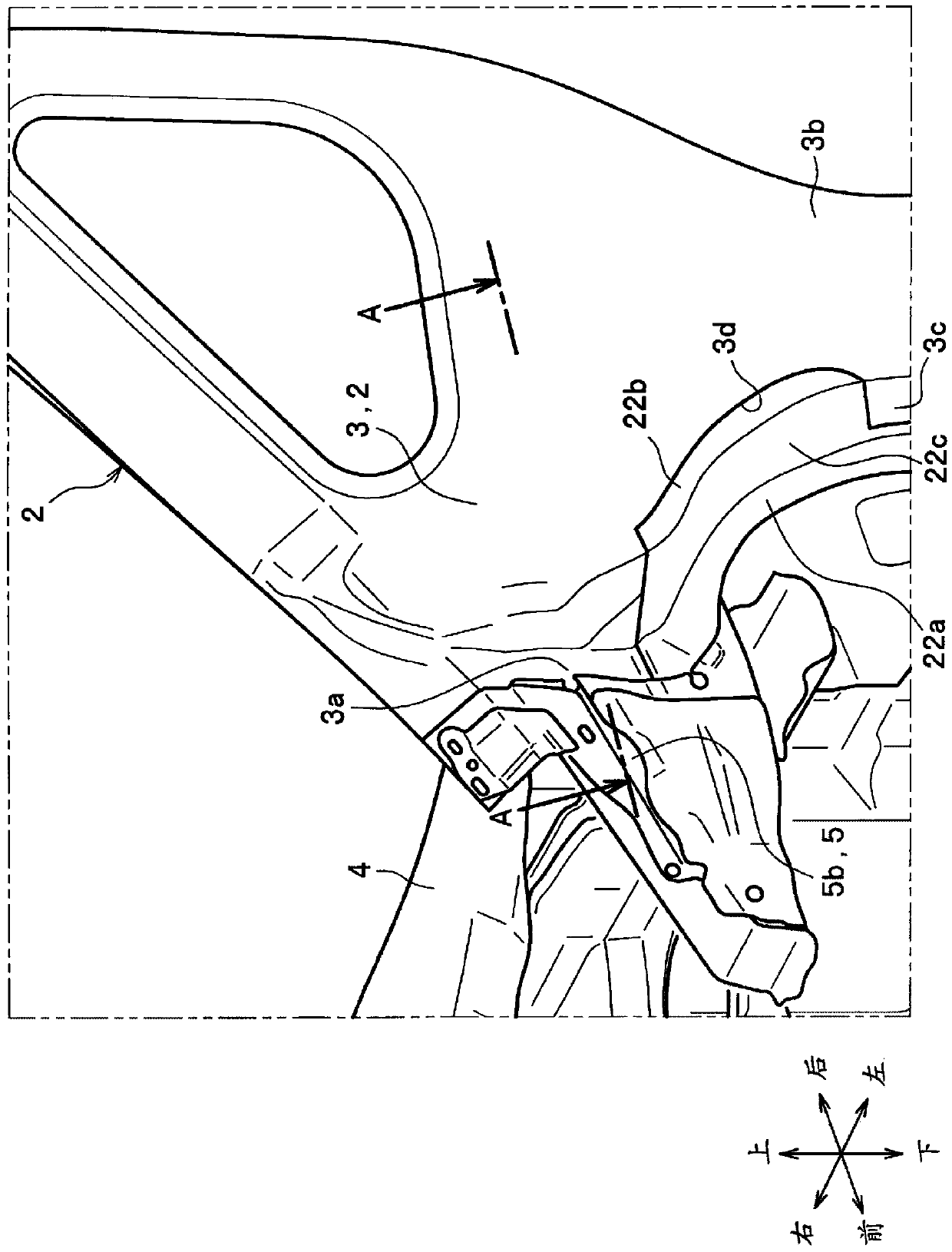

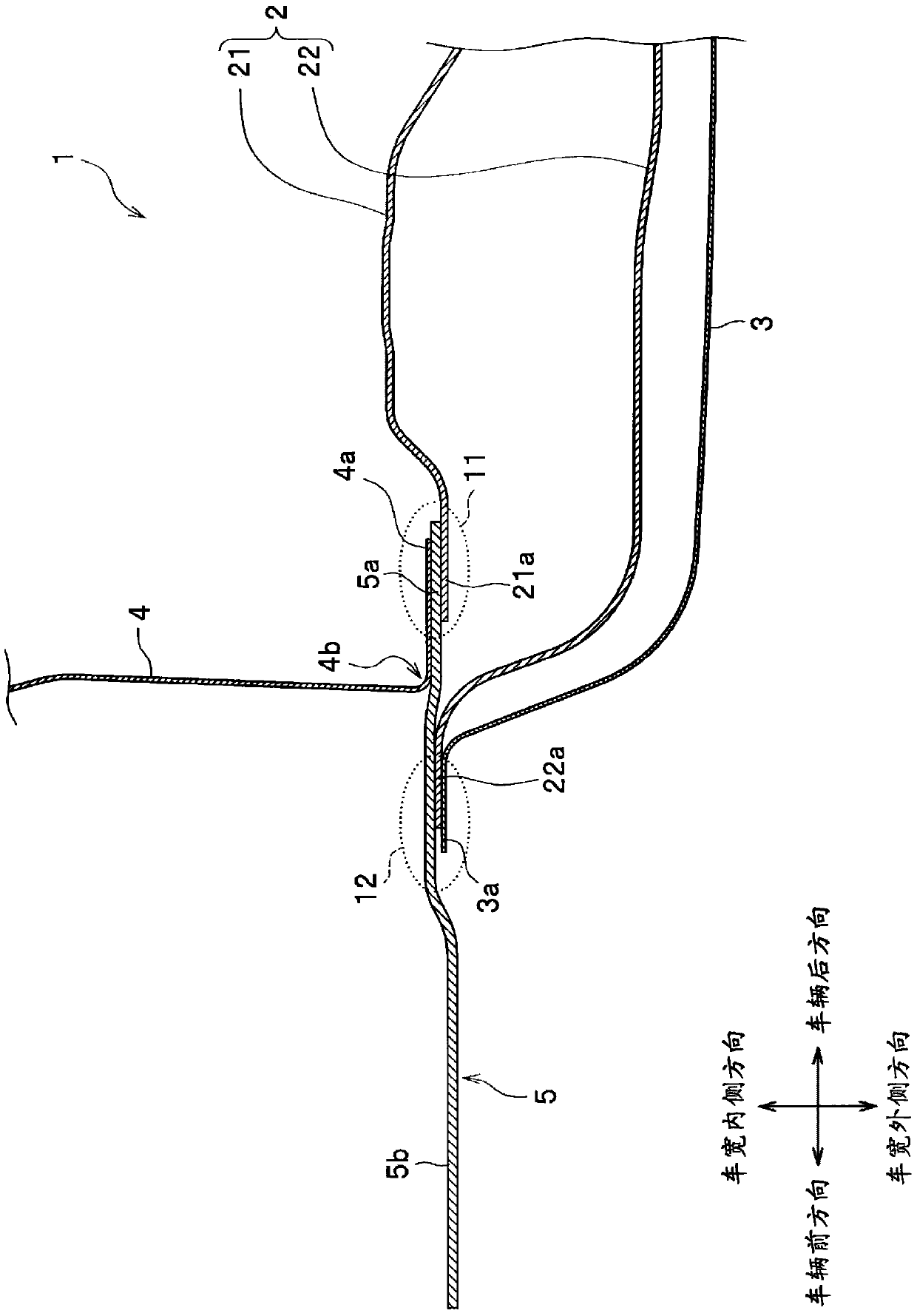

[0047] figure 1 It is the perspective view which looked at the left front pillar part of the vehicle body front structure which concerns on embodiment of this invention from the front left. figure 2 By figure 1 An enlarged perspective view of the front pillar portion surrounded by double-dotted dash lines. image 3 yes figure 2 A-A to see the sectional view. In addition, since the vehicle body front structure of this embodiment is a left-right symmetrical structure, in the following description, the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com