Yarn laying equipment and winding machines

A kind of equipment and yarn technology, which is applied in the field of yarn laying equipment, can solve the problems of wing wheel pair yarn loss and loss, etc., and achieve the effect of overcoming the failure or interruption of the winding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

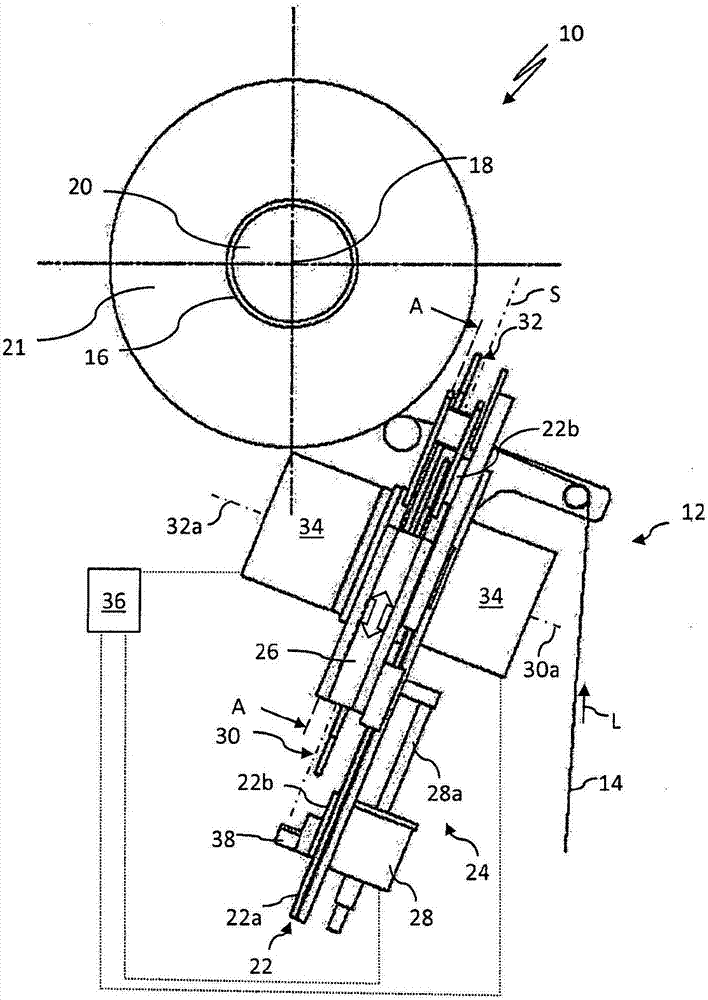

[0027] figure 1 Shown is a partial representation of a winding machine 10 with a laying device 12 for winding a yarn 14 on a bobbin arranged downstream of the laying device 12 in the yarn travel direction L 16 on.

[0028] The bobbin 16 has a bobbin longitudinal axis 18 and is arranged on a bobbin holder 20 . The bobbin holder 20 can be driven circumferentially about the bobbin longitudinal axis 18 of the bobbin 16 . The yarn 14 to be wound can thus be drawn from a feed bobbin (not shown in detail) of the winding machine 10 and wound onto the bobbin 16 to form a yarn package 21 .

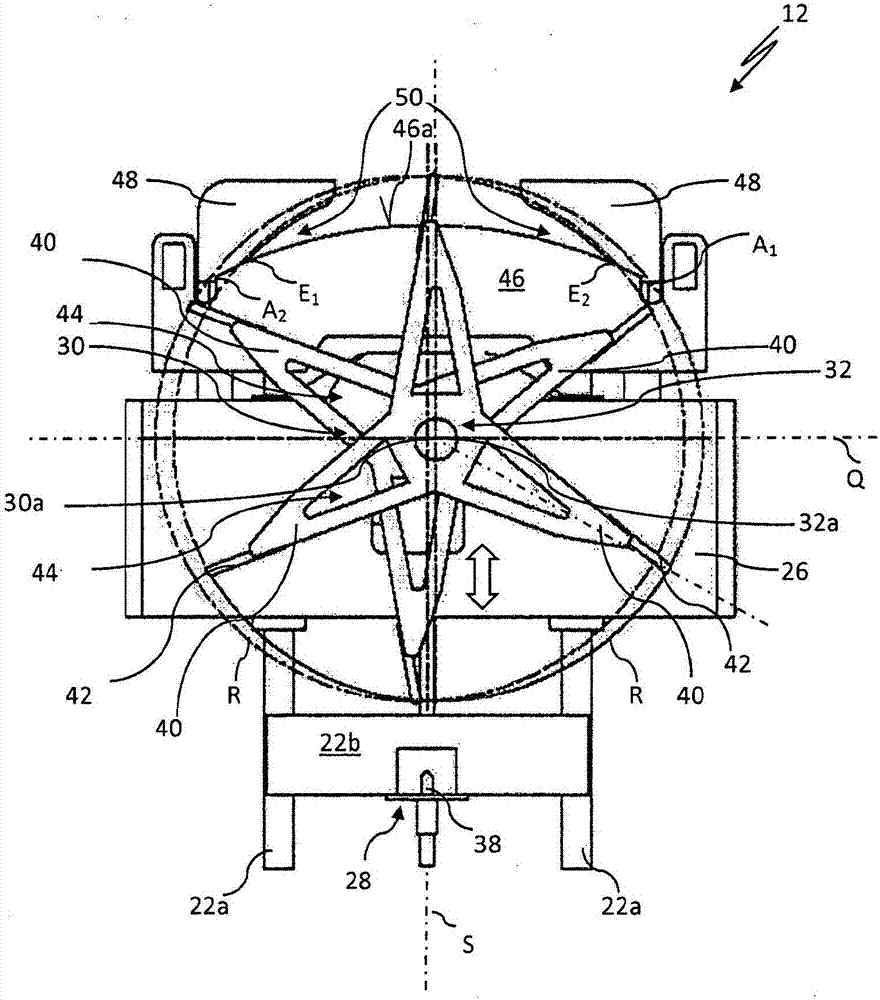

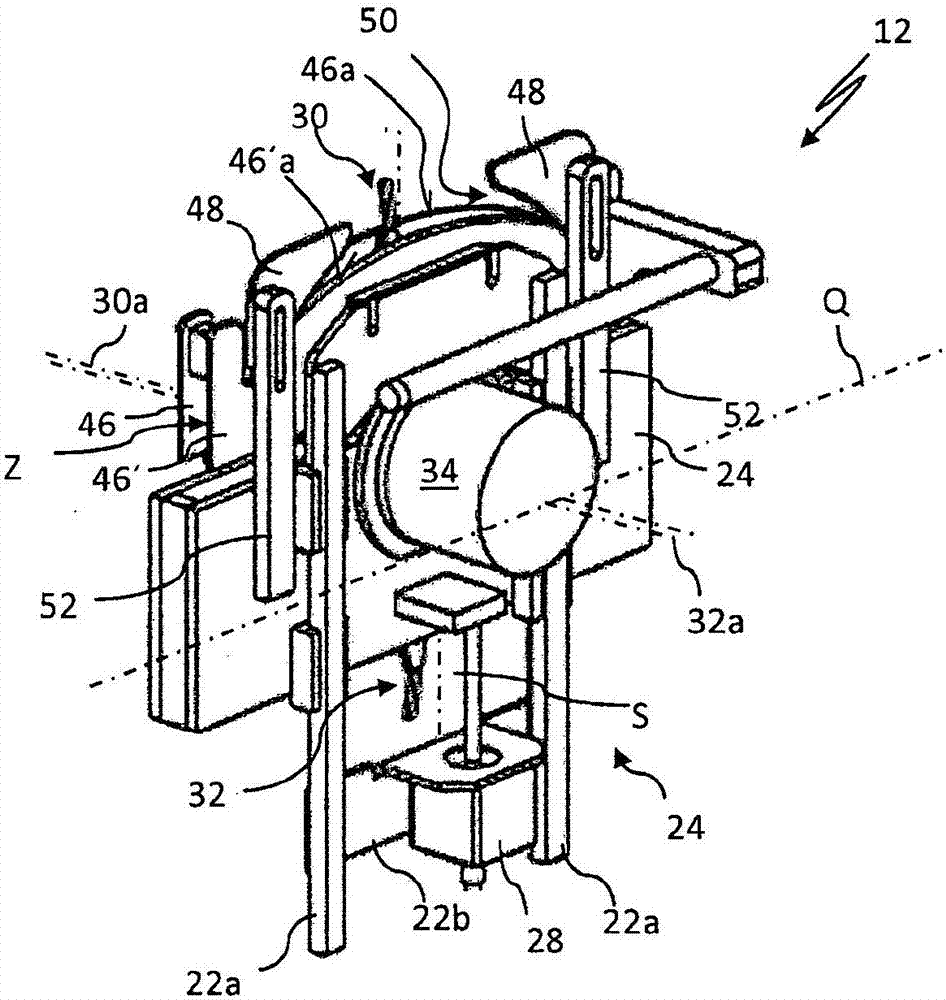

[0029] The yarn laying device 12 has a support frame 22 . The support frame 22 comprises in this example two longitudinal profiles 22 a arranged running parallel to one another, which are connected to each other by two transverse profiles 22 b.

[0030] An adjustment device 24 is arranged on the two longitudinal profiles 22 a of the support frame 22 . The adjustment device 24 includes a (bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com