Stirring mechanism used in sewage treatment pool

A technology for sewage treatment tanks and mixing mechanisms, applied to mixers with rotating mixing devices, mixers, chemical/physical processes, etc., can solve problems such as difficult mixing, mixing blades that cannot move vertically, and unsatisfactory mixing effects. To achieve the effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

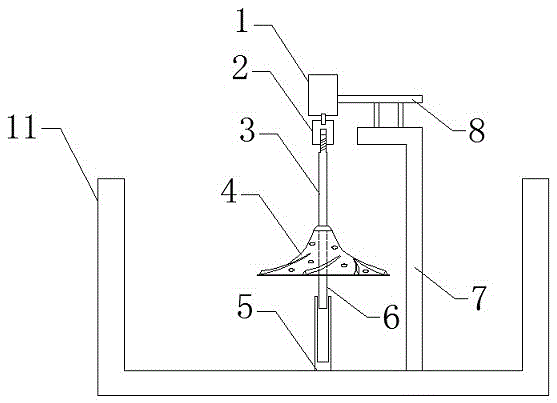

[0024] Example: A stirring mechanism applied in a sewage treatment tank, comprising a bracket 7 fixedly installed in the pool body 11, a motor frame 8 is fixedly connected to the bracket 7, the motor frame 8 is fixedly connected to the stirring motor 1, and the main shaft of the stirring motor 1 is connected to the The shaft coupling 2 is fixedly connected, and the inner hole of the shaft coupling 2 has an internal thread, and the internal thread is adapted to the external thread on the rotating rod 3 to form a pair of threads. Wherein, the rotating rod 3 is a stepped shaft structure.

[0025] In order to increase the torque, the stirring motor 1 is a geared motor.

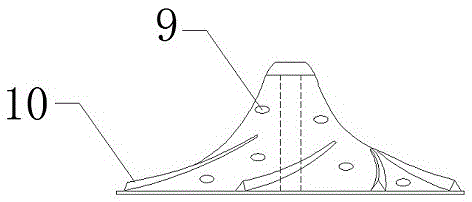

[0026] At the same time, the agitator 4 is an umbrella structure, the agitator 4 has a water filter hole 9, and the agitator 4 has arc-shaped blades 10 outside.

[0027] In order to be able to guide when the agitator 4 moves up and down, the inner top surface of the agitator 4 is fixedly connected to the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com