Ear washing bulb pressure fine-adjustment device and manufacturing method thereof

A technology for fine-tuning devices and manufacturing methods, applied to chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve problems such as difficult cleaning, instability, and poor control of push-pull degrees, and achieve convenient manufacturing and easy operation. Precise, structurally simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 Use plexiglass as the shell material to make a pressure fine-tuning device for ear washing balls:

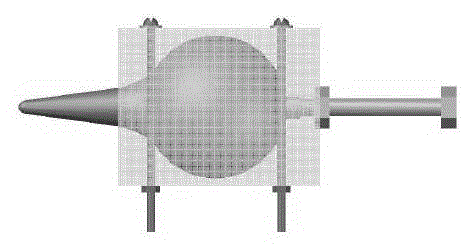

[0021] Prepare 6 plexiglass plates that can be made into cuboids (length 7.6cm, width 6.1cm, height 6.1cm), 5 of which are fixed with adhesive to form a cuboid shell (the right side is not installed), and the left side Open a round hole in the middle of the surface, just to let the long mouth of the ear washing ball pass through, install the right plexiglass plate, open a round hole in the middle of the plate, so that the bolt with the protective cover just passes through, and grind a nut-shaped shallow hole on the outside of the round hole. Groove and fix the nut; finally use 4 sets of screws to reinforce the whole pressure trimming device. main view as figure 1 shown. The ear washing ball pressure fine-tuning device has a regular and beautiful shape, simple and stable operation, and a long service life.

Embodiment 2

[0022] Example 2 Use recycled disposable tea cups as shells to make a pressure fine-tuning device for ear washing balls:

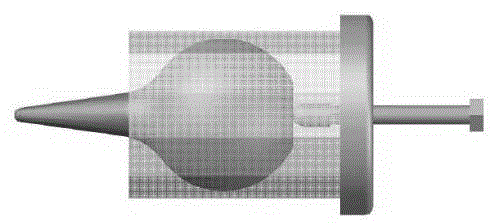

[0023] Recycled disposable open-mouthed tea cup with slightly hard texture (large diameter 6.4cm, small diameter 4.4cm), a round hole is punched in the middle of the bottom of the cup so that the long mouth of the ear washing ball just passes through, and a square plastic plate (length 7cm, width 7cm) is used as the cup The lid is fixed on the mouth of the cup. A round hole is drilled in the center to allow the bolt with the protective sleeve to pass through, and a shallow groove in the shape of a nut is ground on the outside of the round hole to fix the nut. main view as figure 2 shown. The shell material of the ear washing ball pressure fine-tuning device is cheap and easy to obtain, energy-saving and environment-friendly, and the manufacturing process is simple.

Embodiment 3

[0024] Example 3 Use waste plastic bottles as the shell to make a pressure fine-tuning device for ear washing balls:

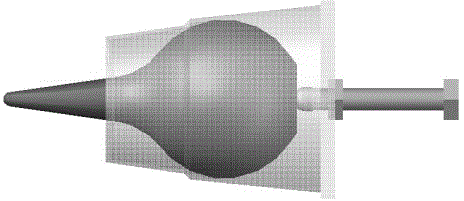

[0025] The bottle containing the chewing gum is a double-layer cylindrical shell with an inner diameter slightly larger than the outer diameter of the ear wash ball. There is a round hole in the bottom of the inner cylindrical material, which can just pass through the long mouth of the ear wash ball, in the middle of the bottle cap. Drill a round hole so that the bolt with the protective sleeve can pass through, and fix the nut with glue on the outside of the round hole. main view as image 3 shown.

[0026] The shell material of the ear washing ball pressure fine-tuning device is cheap and easy to obtain, energy-saving and environment-friendly, the manufacturing process is simple, and it is solid and durable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com