Pre-treatment device used for recycling aluminum scraps

A pretreatment device and technology of aluminum chips, applied in grain processing and other directions, can solve problems such as damage, overloading of screw conveyors, blockage of screw conveyors, etc., and achieve the effect of ensuring pushing power, improving production efficiency and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

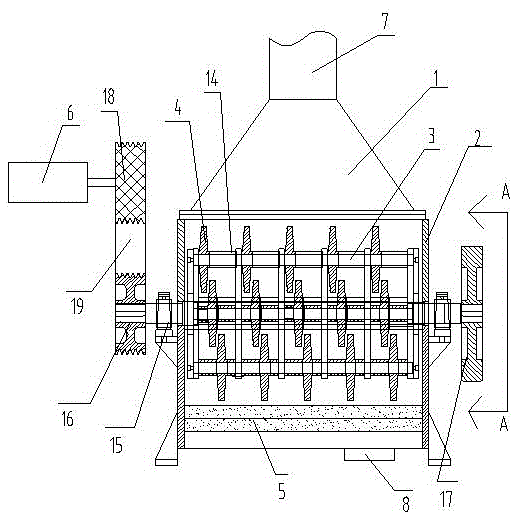

[0022] The present invention will be further described below in conjunction with accompanying drawing.

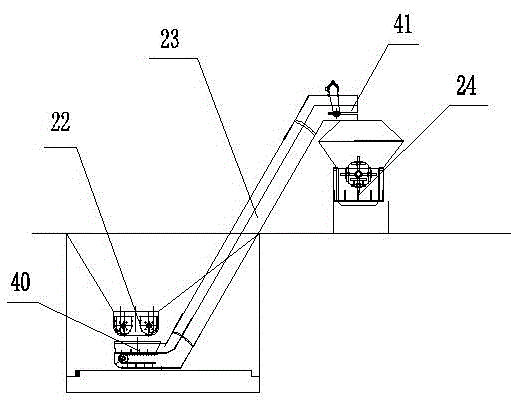

[0023] As shown in the figure, a pretreatment device for recycling aluminum shavings, including double stirring 22, expansion plate elevator 23 and crusher 24;

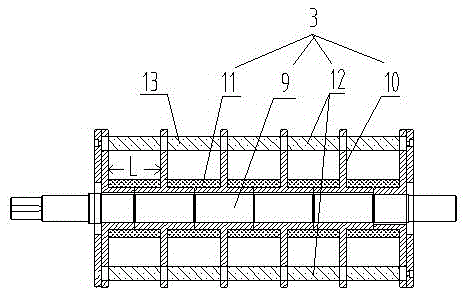

[0024] The duplex stirring 22 comprises a first housing 25, a cycloid reducer 26 and two stirring mechanisms 27, and the first housing 25 comprises a first upper housing 28 and a first lower housing 29, so The cross-sectional shape of the first lower housing 29 is a w-shaped structure, so that two cavities 30 for stirring mechanisms are formed in the first lower housing 29, and the first upper housing 28 is provided with a first receiving hopper 31. The lower casing 29 is provided with a first discharge port 32, and the stirring mechanism 27 includes a seamless pipe 33, a blade 34, a transmission gear 35 and a shaft sleeve 36, and the shaft sleeve 36 is fixed on the first lower casing 29. The outer wall, the seaml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com