Automatic connected line of hinge production line

A production line and hinge technology, applied to door/window fittings, hinged panels, building structures, etc., can solve problems such as low work efficiency, low degree of automation, and low product quality, and achieve improved work efficiency, simple and compact structure, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

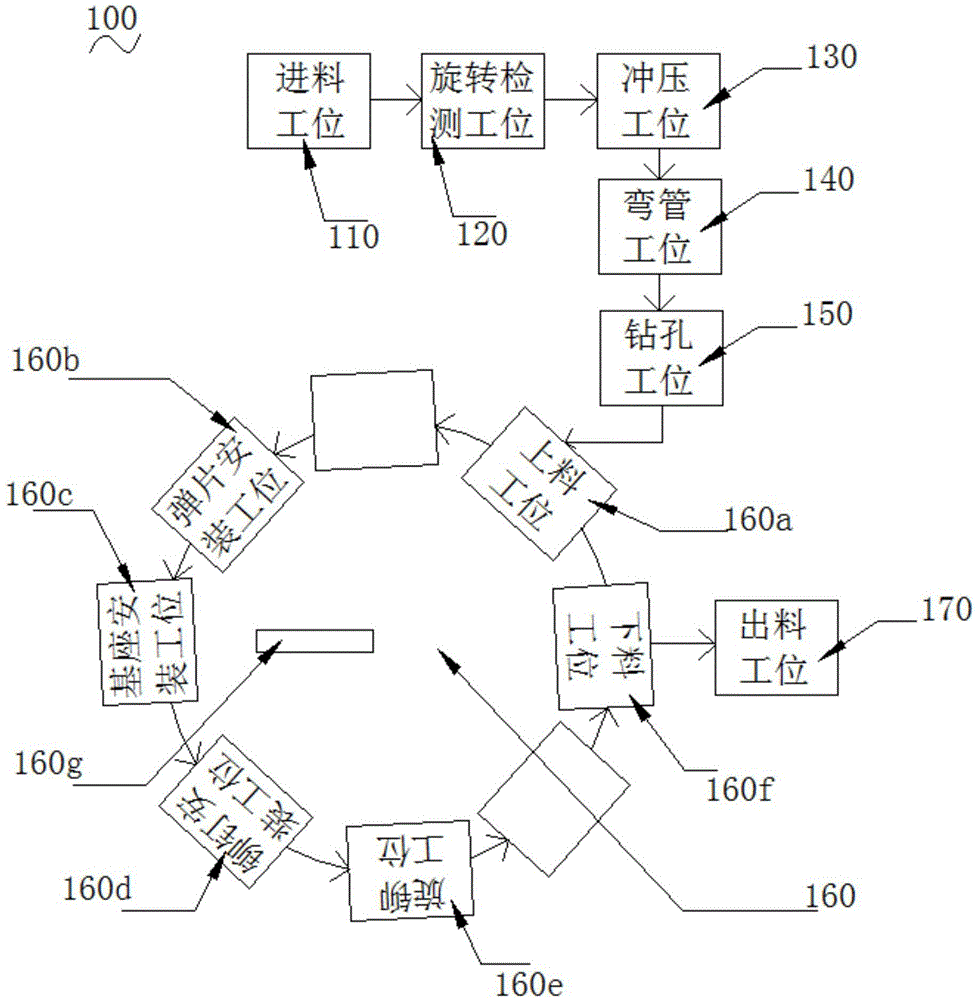

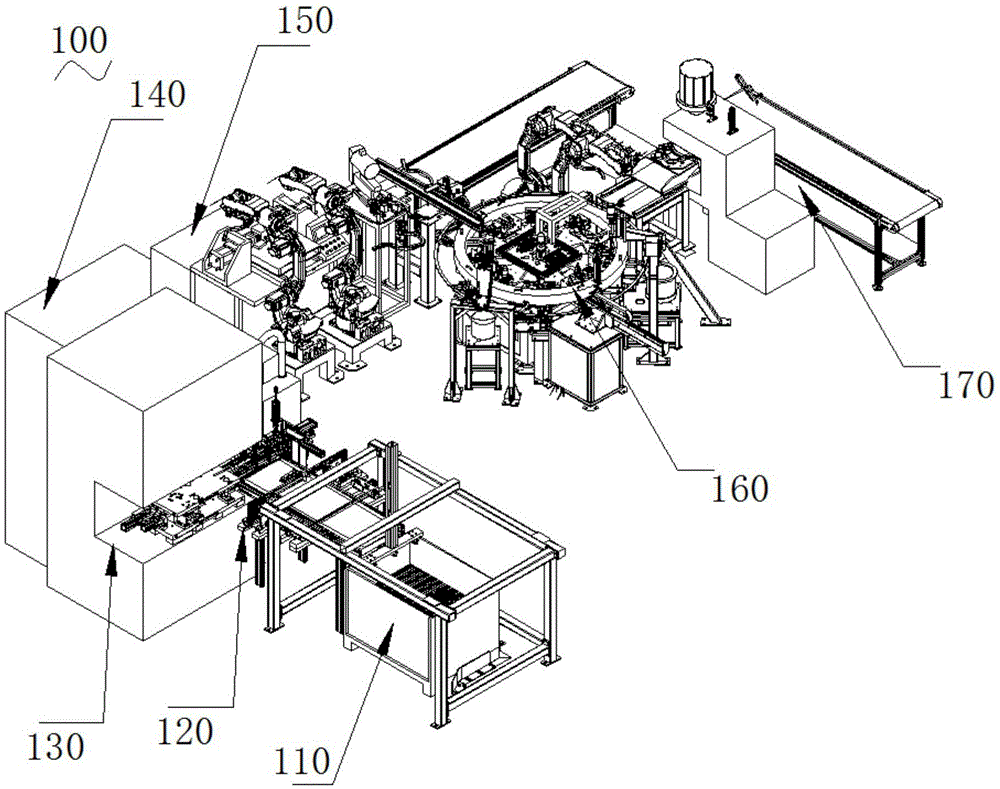

[0037] Such as figure 1 with figure 2 Shown are respectively the structure block diagram and the structure schematic diagram of the present invention.

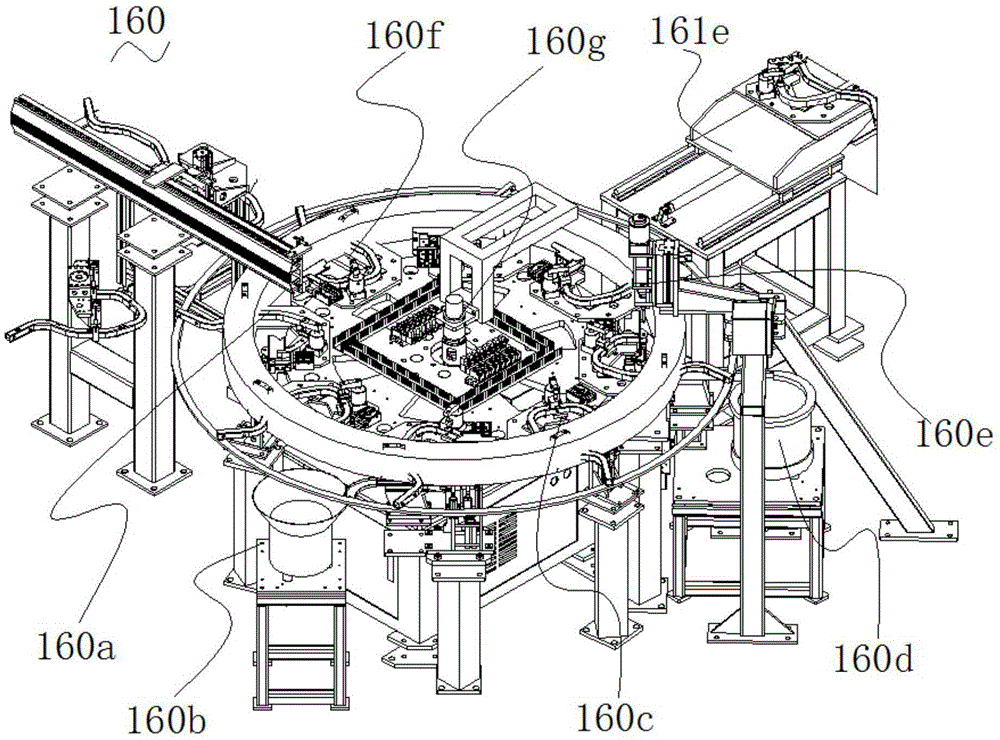

[0038] The automatic connection line 100 of the hinge production line includes the feeding station 110 for feeding the raw material square tube, the rotating inspection station 120 for ensuring that the raw material square tube has the welded side facing upwards, and is used for stamping the raw material square tube A stamping station 130 for obtaining stamped parts, a pipe bending station 140 for bending the stamped parts into semi-finished pipes, and a perforator for drilling the sides and ends of semi-finished pipes to obtain pipes with holes Position 150, a post-processing mechanism 160 for post-processing the bent pipe with holes to obtain a finished hinge, and a discharge station for discharging the finished h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com