Stress relief process for ultraprecise optical resin lens

A resin lens, ultra-precision technology, applied in optical components, applications, and other household appliances, etc., can solve problems such as lens cracking, internal stress, and large molecular side effects, and achieve resolution improvement, internal stress reduction, and elimination of internal stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

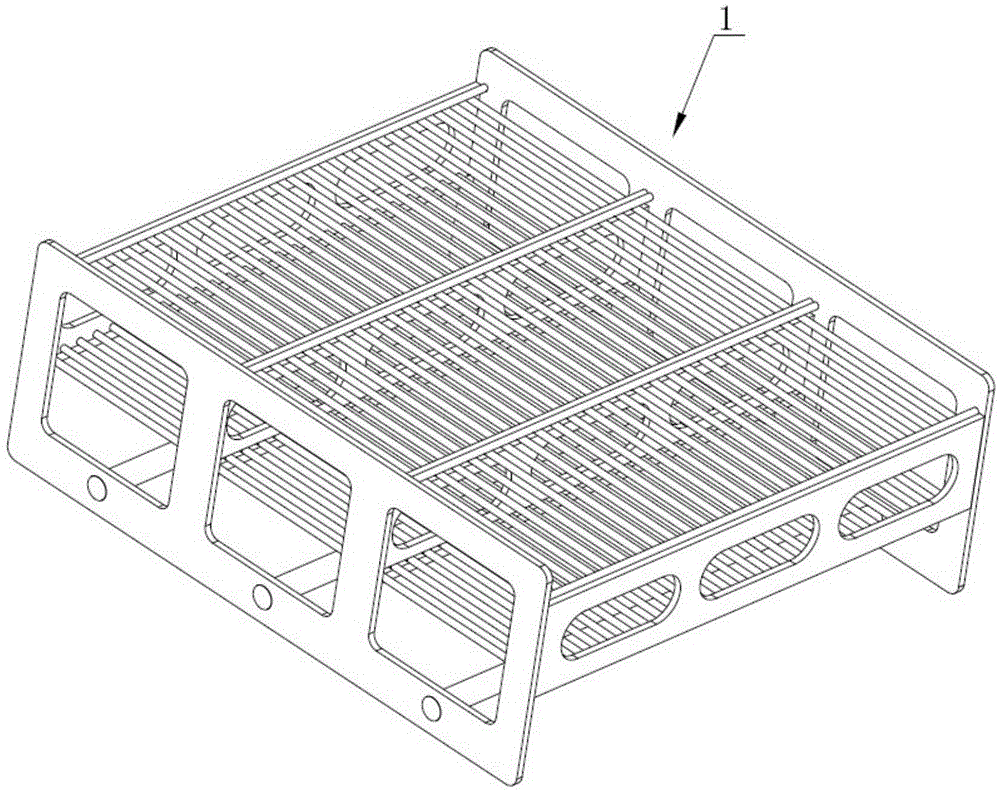

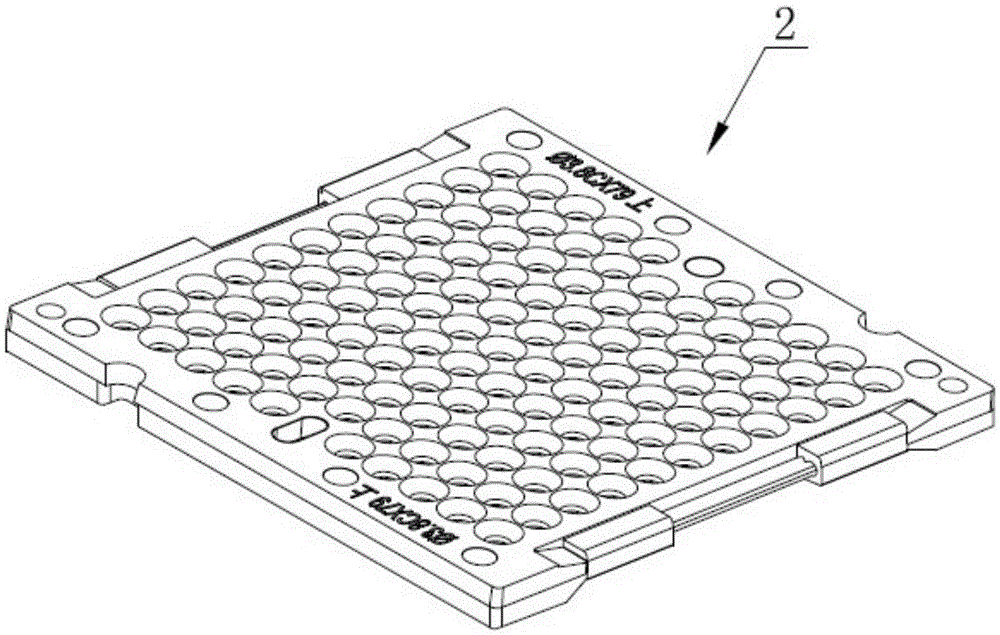

[0020] Such as figure 1 and figure 2 As shown, an optical ultra-precision resin lens stress-relieving process includes the following steps:

[0021] A. Put the resin lens into the cleaning column 1;

[0022] B. Wrap the cleaning column 1 equipped with resin lenses with high-temperature-resistant plastic wrap;

[0023] C. Put the wrapped cleaning column 1 into a dust-free oven for baking, the baking time is 3 to 5 hours, and the baking temperature is 75 to 95 degrees Celsius;

[0024] D. Cool naturally after baking.

[0025] In this embodiment, in step A, first put the resin lens into the lens holder 2, and then put the lens holder 2 together with the resin lens into the cleaning column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com