Power assembly bracket device for pure electric vehicle

A pure electric vehicle and powertrain technology, which is applied to electric power units, power units, control units, etc., can solve the problems of uneven distribution of force on the longitudinal beams of automobiles, inability to centrally fix them, and scattered installation positions, so as to avoid unbalanced forces. Uniform, enhanced cushioning effect, reduced vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

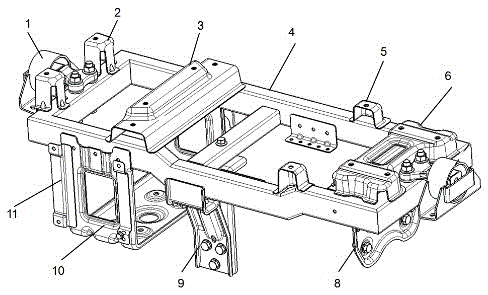

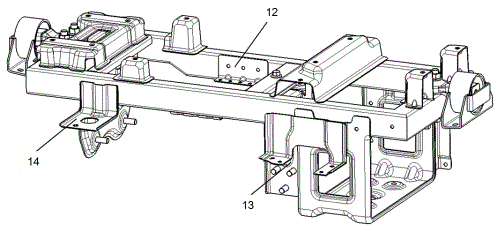

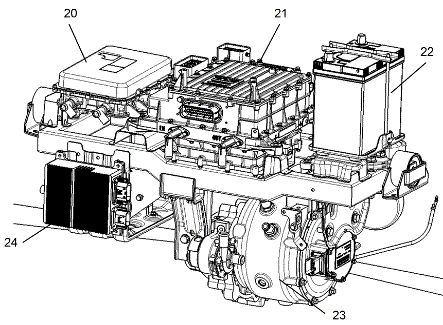

[0029] Embodiment 1: as figure 1 , 2 , shown in 3 and 4, a powertrain bracket device of a pure electric vehicle, including a main beam 4, the main beam is a rectangular frame structure, and the upper surface of one end in the width direction of the main beam is provided with a charging device for fixing the charger 20. The upper surface of the charger bracket 2 and the other end is provided with a battery mounting plate 6 for fixing the battery pack 22; the upper surface of the main beam in the length direction is near the charger bracket and is provided with a motor controller mounting plate 3 for fixing the motor controller 21. The controller mounting plate is perpendicular to the length direction of the main beam; the upper surface of the main beam in the length direction is symmetrically provided with a motor controller mounting bracket 5 used in conjunction with the motor controller mounting plate near the battery mounting plate; The air-conditioning compressor mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com