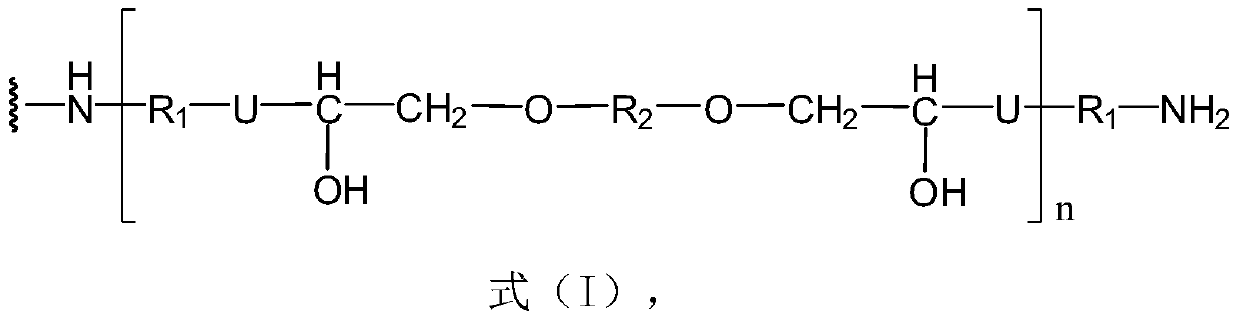

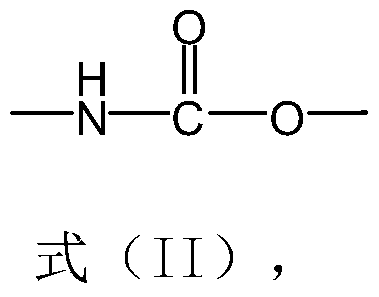

A kind of non-isocyanate polyurethane carbon nanotube modified epoxy resin composite material and preparation method thereof

A carbon nanotube modified, non-isocyanate technology, which is applied in the field of non-isocyanate polyurethane carbon nanotube modified epoxy resin composite materials and its preparation, can solve the problem of inability to effectively improve the flexibility of epoxy resin composite materials and the addition of carbon nanotubes. Solve problems such as limited amount, difficult to disperse paint, etc., achieve good storage stability, improve processability, and not easy to settle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

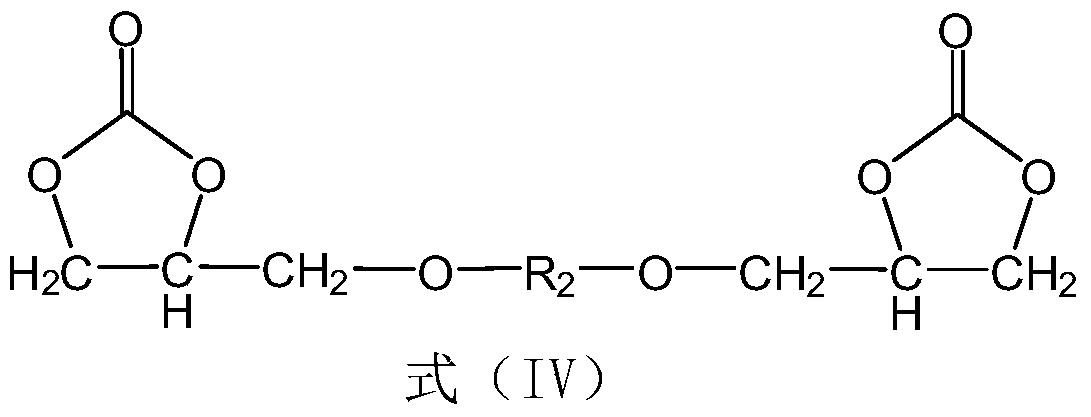

[0046] Take epoxy resin (1,4-Butanediol diglycidyl ether, SIGMA-ALDRICH, 100phr) and tetrabutylammonium bromide (tetrabutylammonium bromide, TBAB, SIGMA-ALDRICH, 0.5phr) and place in a high-pressure reaction tank, seal the reaction tank, At this time, the exhaust valve of the reaction tank was opened, and the carbon dioxide was passed into the reaction tank through the inlet valve, and the air content of the reactant was reduced for 10 minutes. Then close the exhaust valve, pass carbon dioxide into the reaction tank and make the carbon dioxide pressure in the reaction tank reach 8atm, heat the reaction tank to 140°C, then increase the carbon dioxide pressure to 10atm, continue the reaction for 5 hours, and obtain the cyclocarbonate product BDCE , by 1HNMR analysis, epoxy functional group 99%.

Embodiment 2

[0048] Get cyclocarbonate BDCE (290g) and dibasic amine D-230 (460g) was placed in the reaction tank, and the temperature was raised to 50°C for 4 hours, and the viscosity of the mixture increased with the reaction time, and the non-isocyanate polyurethane prepolymer NIPU-NH was obtained. 2 .

[0049] Preparation of non-isocyanate polyurethane modified carbon nanotubes:

Embodiment 3

[0051] Multi-walled carbon nanotubes (CNT Co.LTd., C Tube -100) into concentrated sulfuric acid (98%) and nitric acid (68%) mixture (v / v=3 / 1) mixed solution (carbon nanotubes: mixed acid solution = 1g: 100mL), oscillated by 40kHz ultrasonic wave for 30 minutes After that, the temperature was raised to 60°C for 4 hours, and the obtained product was washed with a large amount of deionized water, and filtered with a PVDF filter membrane (25mm 0.45um) until the pH value was approximately equal to 7, and the product was dried in a vacuum oven at 50°C , to obtain carboxylated carbon nanotubes (MWNT-COOH). After acid value analysis, the product carboxylic acid concentration was 0.186mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com