A kind of residual oil hydrotreating method

A technology for hydrogenation and treatment of residual oil, which is applied in hydrotreating process, treatment of hydrocarbon oil, petroleum industry, etc., can solve the problems of low yield of gasoline and diesel oil, blockage of equipment, etc., so as to reduce equipment investment and improve product distribution. , the effect of reducing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This example is used to illustrate the method for hydrotreating residual oil provided by the present invention.

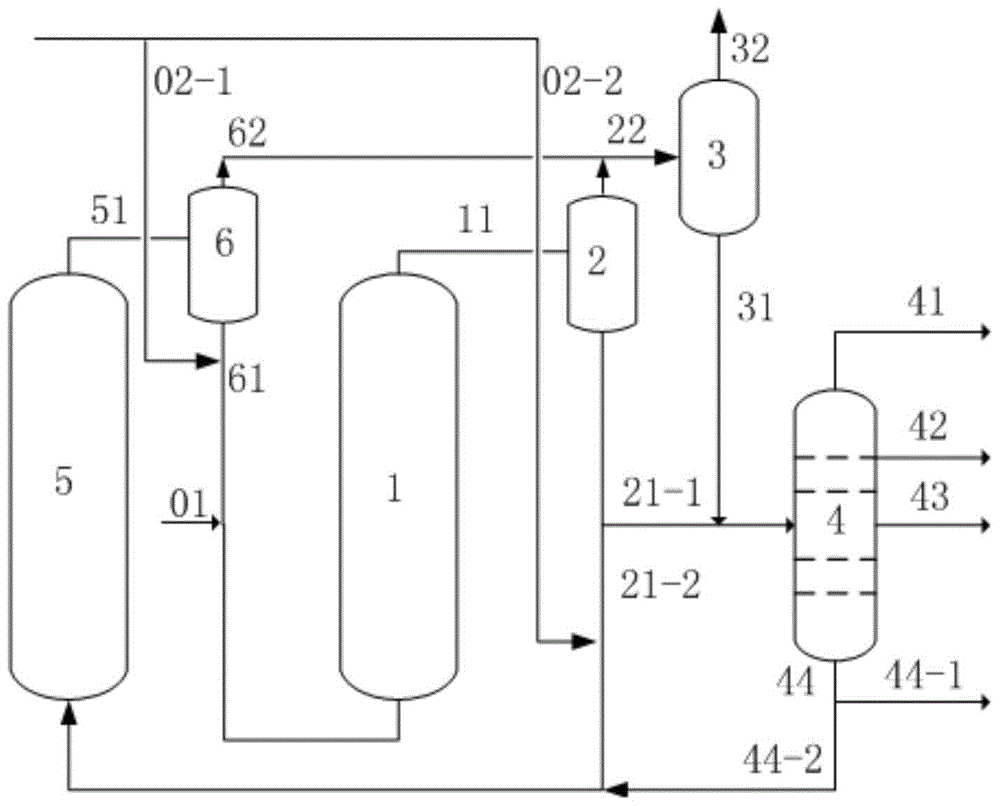

[0054] Embodiment 1 is carried out on the laboratory fluidized bed evaluation device, and its process flow diagram is as follows figure 1As shown, its process conditions and evaluation results are shown in Table 3. The toluene insolubles in Table 3 represent the "sludge" content, and the higher the content, the more unstable the operation of the ebullated bed.

Embodiment 2

[0056] This example is used to illustrate the method for hydrotreating residual oil provided by the present invention.

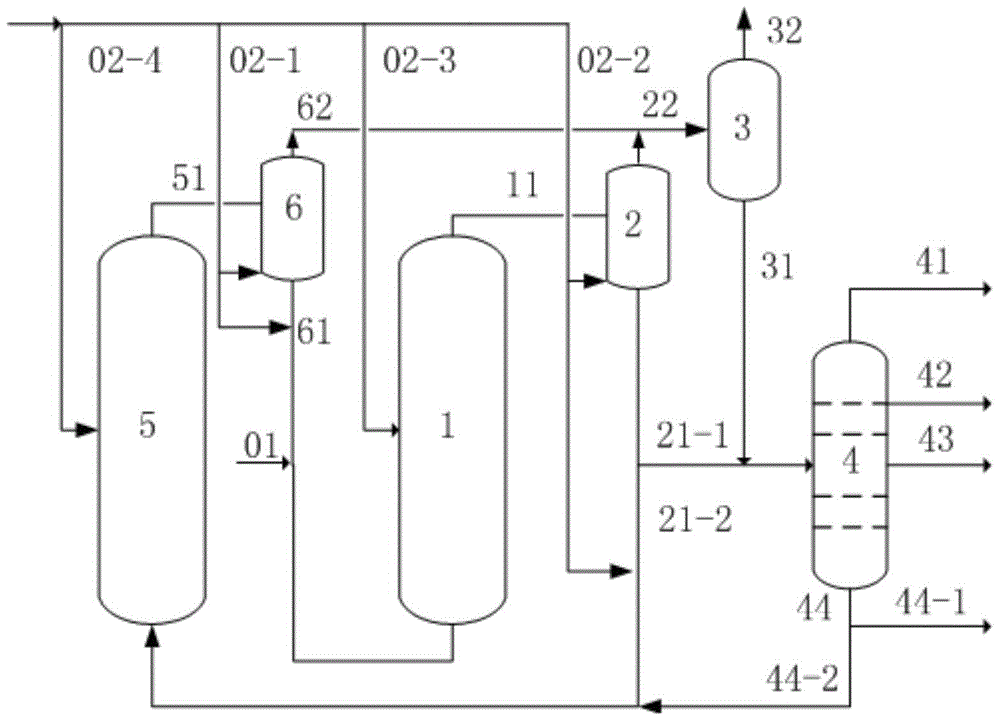

[0057] Embodiment 2 is carried out on the laboratory ebullated bed evaluation device, and its process flow diagram is as follows figure 2 As shown, but there is no stripping of hydrogen in the first high-pressure separator and the third high-pressure separator, and there is no circulation of wax oil and hydrogenated residue in the fractionation tower. The process conditions and evaluation results are shown in Table 3.

Embodiment 3

[0059] This example is used to illustrate the method for hydrotreating residual oil provided by the present invention.

[0060] The process flow chart of embodiment 3 is the same as that of embodiment 2, and its difference is that the first high-pressure separator and the third high-pressure separator of embodiment 3 are all equipped with stripping hydrogen, and its process conditions and evaluation results are as shown in table 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com