Oppositely penetrating steel bar and oppositely penetrating vertical insert plate type beam column two-way rigid joint

A technology for piercing steel rods and inserts, which is applied in construction, building construction, etc., can solve the problems of difficult casting of rigid joints, low level of industrialization, etc., and achieves the effect of processing difficulty, cost reduction, and simple processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

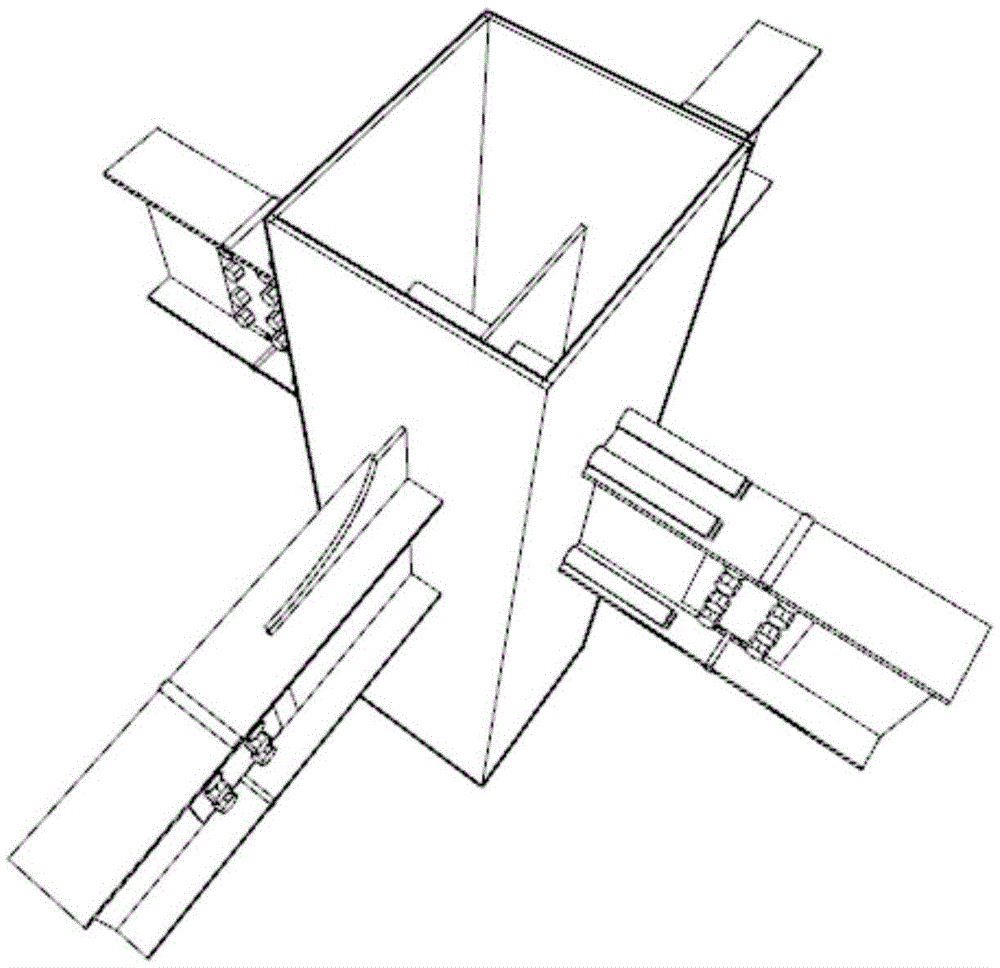

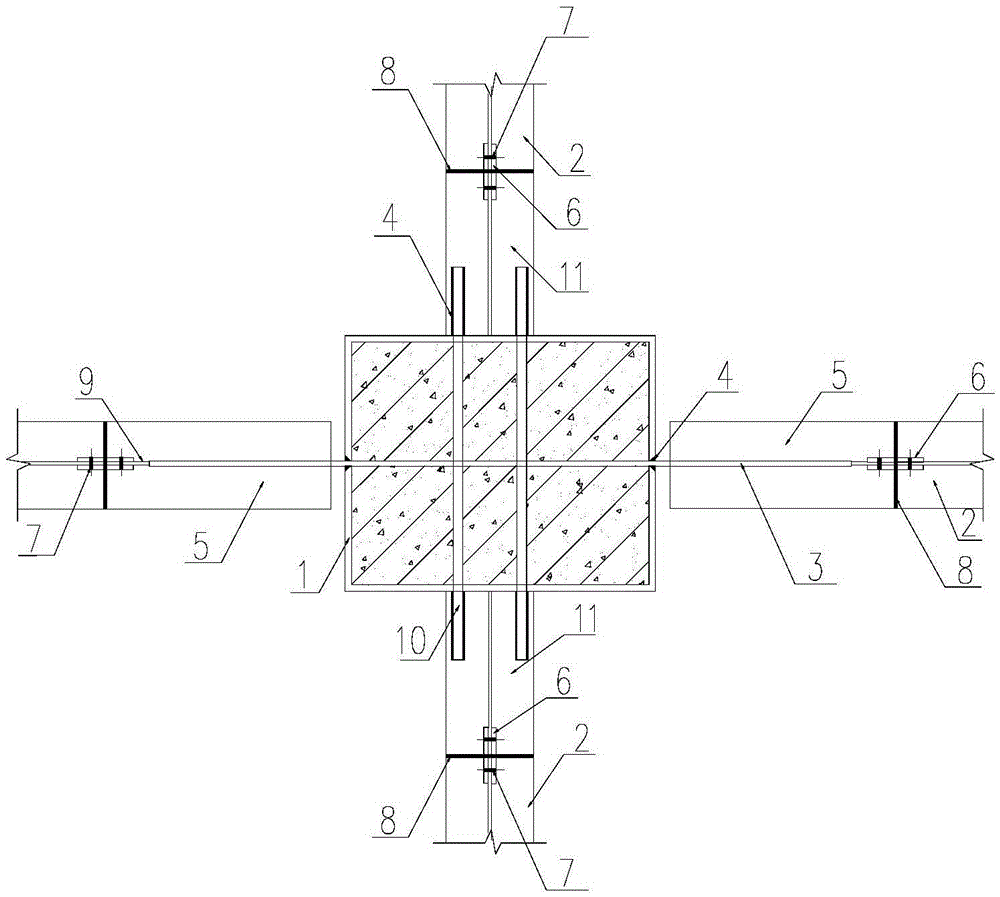

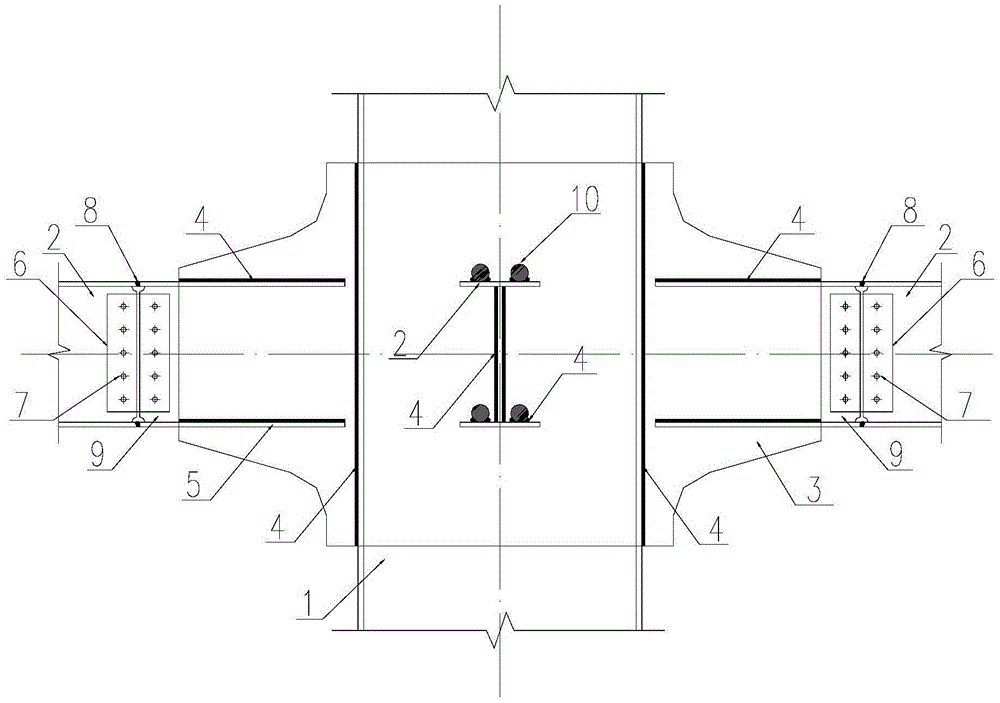

[0046]An embodiment of the present invention is figure 1 and figure 2 As shown, it includes concrete-filled steel pipe column 1, steel beam 2, insert plate 3, steel rod 11, insert plate corbel and steel rod corbel, and two mutually perpendicular directions of steel pipe concrete column 1 are respectively inserted with insert plate 3 and four steel rod 10.

[0047] The wall plate of the steel pipe concrete column 1 is provided with a strip groove where the insert plate 3 penetrates, and the insert plate 3 passes through the strip groove and is welded to the wall plate through the weld seam 4 . The inserting plate 3 runs through both ends of the steel pipe concrete column 1 and connects to the inserting plate corbel: there is an axial strip groove in the middle of one end of the inserting plate corbel flange 5, and the inserting plate 3 is inserted in the inserting plate corbel The flange 5 is in the strip groove and welded with the plate corbel flange 5 through the weld 4, t...

Embodiment 2

[0050] Example 2 as figure 1 and figure 2 As shown, the difference from Embodiment 1 is that four steel bars 10 are welded on the lower surface of the steel bar corbel flange 1 at the same time, as Figure 4 and Figure 7 shown.

Embodiment 3

[0052] Example 3 as figure 1 and figure 2 As shown, the difference from Embodiment 1 is that four steel rods 10 are inserted and welded inside the steel rod corbel flange 1 at the same time, as Figure 5 and Figure 8 shown. The center of the steel rod 10 can be aligned with the center of the steel rod corbel flange 1, where the steel rod corbel flange 1 is provided in the strip groove in the middle along the axial direction and welded by the weld seam 4, and the steel rod 10 is inserted into the steel rod The position of the corbel flange 1 is slotted and then welded by the weld seam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com