On-line lubricant sedimentation system

A lubricant and branch technology, applied in the field of lubricant on-line sedimentation system, can solve the problems of ineffective sedimentation, defects, unreasonable partition, etc., and achieve the effects of reducing the content of lubricant residues, improving quality, and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

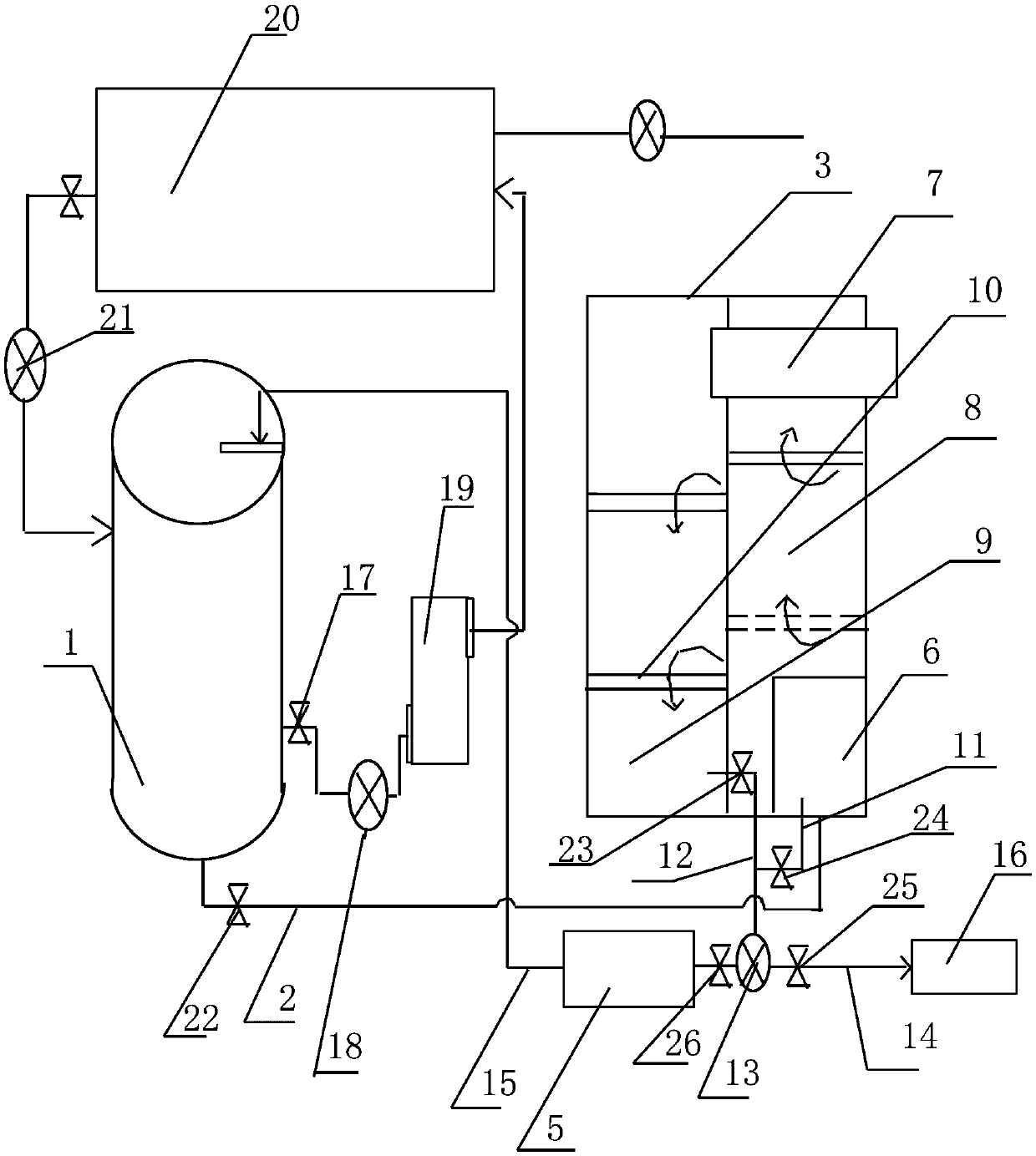

[0008] exist figure 1 Among them, the present invention provides an online lubricant sedimentation system, which is provided with a circulation tank 1, a tank bottom drain pipe 2, a discharge pool 3, a sewage pump 13 and a centrifuge 5, and the discharge pool 3 is provided with a buffer tank 6 , slag scraping device 7, overflow baffle 10, settling area 8 and overflow collection tank 9, the bottom of circulation tank 1 is connected with the input port of buffer tank 6 through tank bottom drain pipe 2, and the output port of buffer tank 6 is upward Sequentially pass through the settling area 8 and communicate with the input port of the slag scraping device 7, and the output port of the slag scraping device 7 passes through the overflow baffle plate 10 to communicate with the input port of the overflow collection tank 9 in turn, and the output of the overflow collection tank 9 The outlet is divided into branch road I11 and branch road II12, branch road I11 is connected with buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com