A device for testing a stress state of an e-shaped elastic strip of a railroad fastener

A stress state, railway fastener technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of insufficient fastener pressure, difficult on-site testing, e-shaped elastic strip breakage, etc. The method is simple and economical The effect of detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

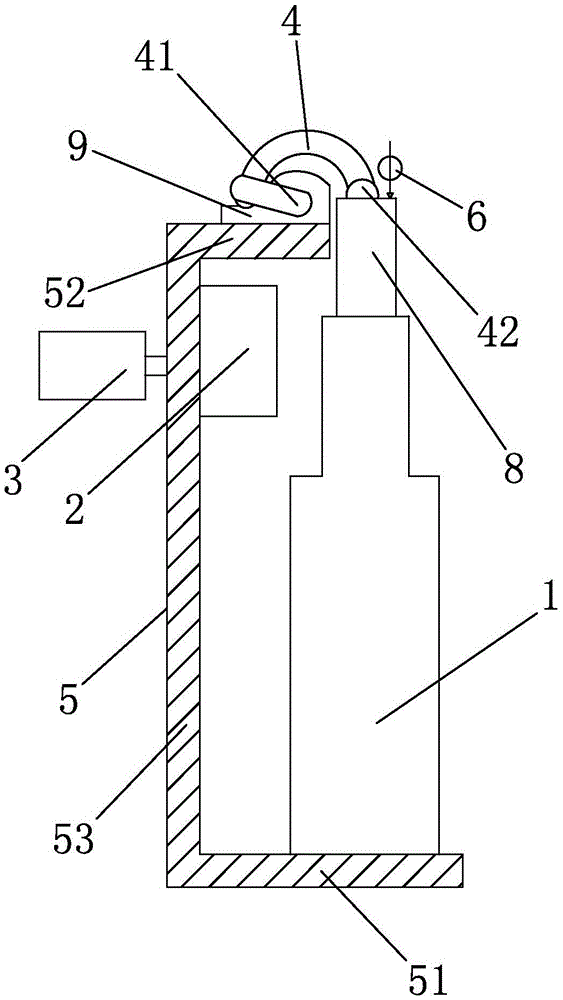

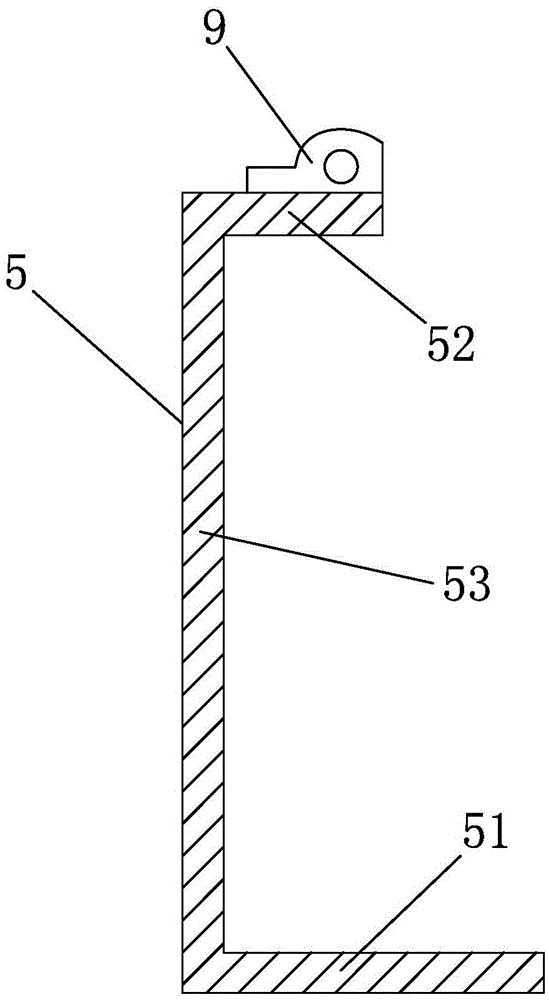

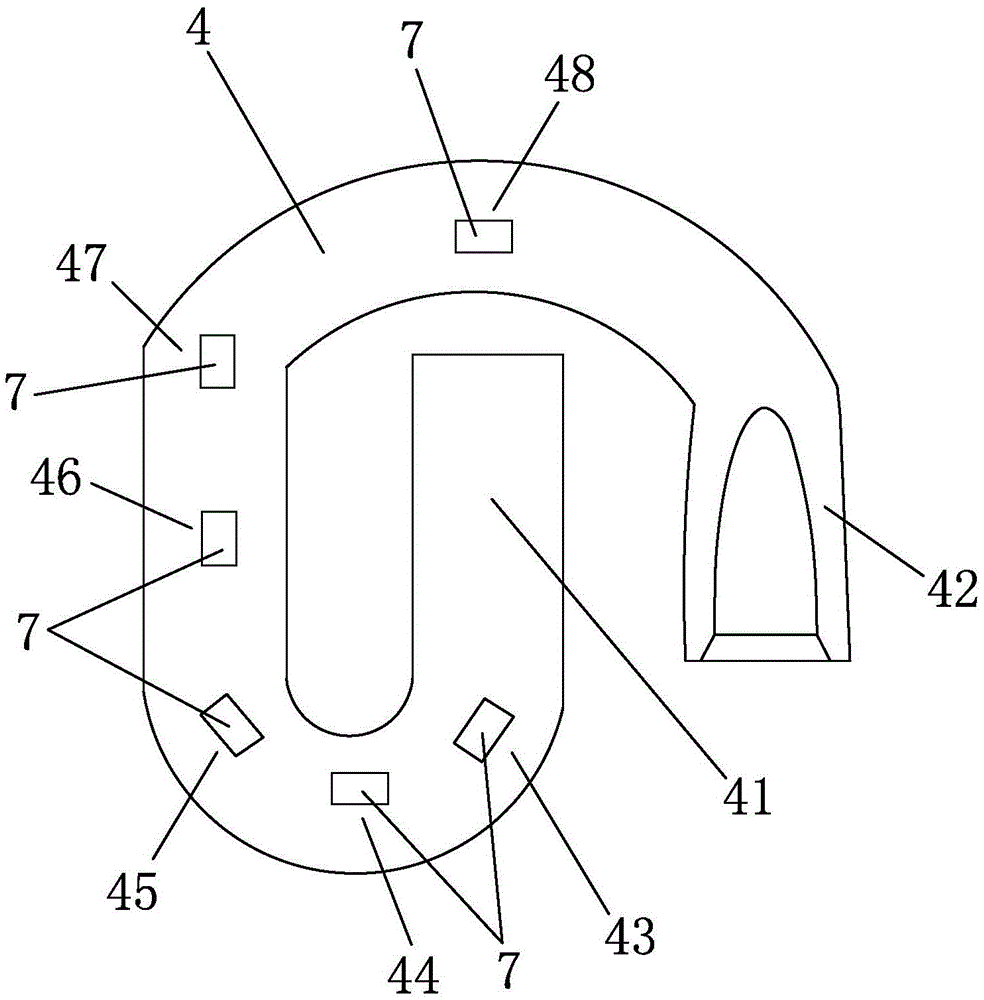

[0023] Such as figure 1 , 2 , shown in 3, a kind of device that is used for the test of the stressed state of railway fastener e-type elastic strip, described device comprises jack 1, data acquisition processor 2, data display screen 3, is used for and the e-type elastic strip to be tested 4 The middle limb 41 is fixedly assembled together with the force bearing bracket 5, the electronic displacement gauge 6 for measuring the vertical displacement of the toe end 42 of the e-shaped elastic strip 4 to be tested and the strain sensor attached to the upper surface of the e-shaped elastic strip 4 to be tested 7; the end of the ejector rod of the jack 1 is provided with a load cell 8 for propping up on the bottom surface of the toe end 42 of the e-shaped elastic bar to be tested; the measuring head of the electronic displacement meter 6 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com