A method for calculating the maximum displacement and bending stress in a process of pipe cleaning of a natural gas pipeline crossing structure

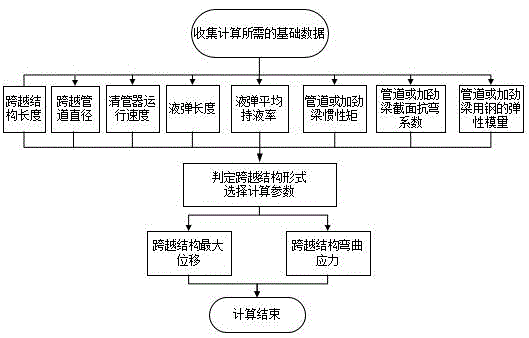

A technology for natural gas pipelines and spanning structures, which is applied to the calculation field of maximum displacement and bending stress in the process of pigging spanning structures of natural gas pipelines, and achieves the effects of clear calculation process, small calculation amount and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

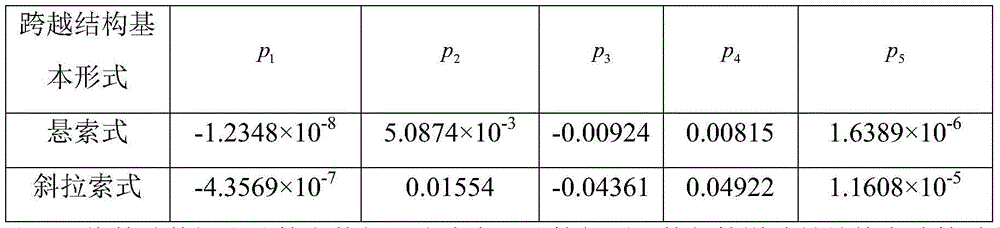

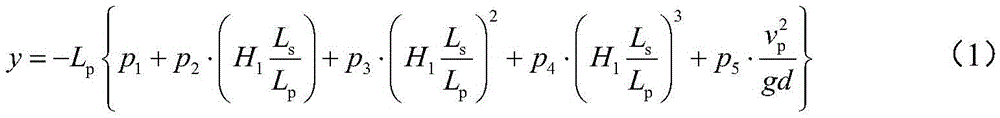

[0061] Example 1: The length of a natural gas suspension cable spanning structure is 320m, the outer diameter of the pipeline is 1016mm, the running speed of the pigging ball is 3.2m / s, the length of the liquid bomb is 83m, and the average liquid holdup rate is 0.6. There are stiffening beams in the spanning structure , the section moment of inertia of the stiffened beam is 61.5m 4 , the bending section coefficient is 24.6m 3 , the modulus of elasticity of the steel is 2.06×10 5 MPa, find the maximum displacement and bending stress of the pipeline during the pigging process.

[0062] Step 1: The collected basic parameters include the span length L of the natural gas pipeline across the structure p =320m, crossing pipeline diameter d=1.016m, pig operating speed v p =3.2m / s, the liquid elastic length L in front of the pig when reaching the spanning structure s =83m, liquid holdup H l =0.6, the section moment of inertia of the stiffened beam is I z =61.5m 4 , the bending s...

example 2

[0072] According to the calculation results, the bending stress of the spanning structure is positive, indicating that it is stretched during the pigging process, but its value is small and will not cause damage to the spanning structure. Therefore, the spanning structure of the natural gas pipeline in this example is safe during the pigging process. Example 2: The spanning length of a natural gas stay cable is 200m, the outer diameter of the pipeline is 426mm, the running speed of the pigging ball is 3m / s, the liquid elastic length is 75.4m, the average liquid holdup is 0.4, the section moment of inertia of the pipeline is 2.83×10 -4 m 4 , the bending section coefficient is 1.32×10 -3 m 3 , the modulus of elasticity of the steel is 2.10×10 5 MPa, find the maximum displacement and bending stress of the pipeline during the pigging process.

[0073] Step 1: The collected basic parameters include the span length L of the natural gas pipeline across the structure p =200m, cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com