Technique for shortening activation time of thermal batteries

A process method and technology of activation time, applied in the direction of primary battery use/maintenance, primary battery to battery grouping, delay action cells, etc. The effect of time and craftsmanship is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

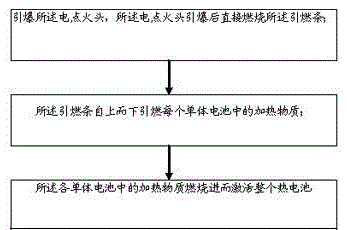

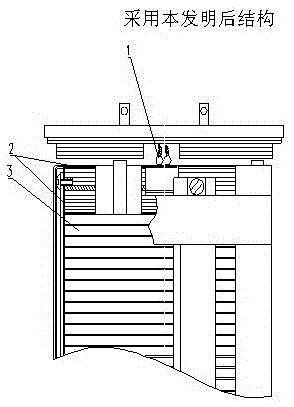

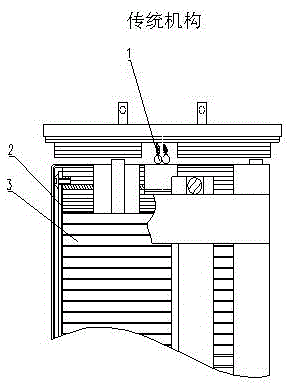

[0014] The unit battery provided by the embodiment of the present invention has a diameter of 68mm, a total height of 95mm, a working load of 16A, and a low temperature working temperature of -45°C. The temperature is low, in order to ensure that the activation time of the battery meets the requirements, it is necessary to carry out the distribution design of the ignition bars in the stack according to the method of the present invention; figure 1 , Figure 2(a) and Figure 2(b) As stated above, the present invention provides a method for shortening the activation time of a thermal battery. The thermal battery is a stack composed of a plurality of single cells connected in series and in parallel. The thermal battery includes an electric ignition head 1, an ignition strip 2, a heating substance 3. The method includes the following steps:

[0015] (1) The electric ignition head 1 is detonated by means of electric activation, and the ignition strip 2 is directly burned after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com