Automatic sheet arranging device for grooved type commutator

A commutator and automatic row technology, applied in the commutator field, can solve the problems of increasing difficulty, large deformation of the plastic sleeve, and difficulty in inserting the copper sheet of the commutator into the plastic sleeve, etc., and achieves the effect of improving production efficiency and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

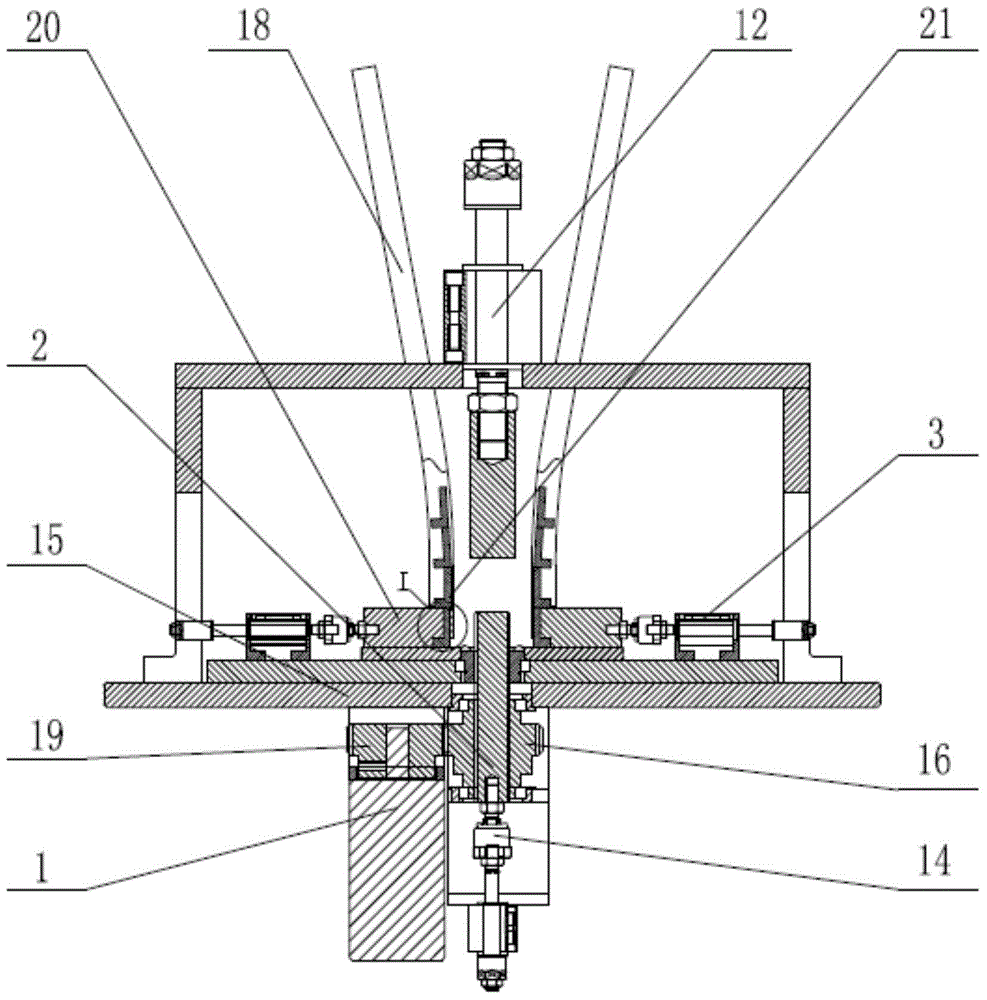

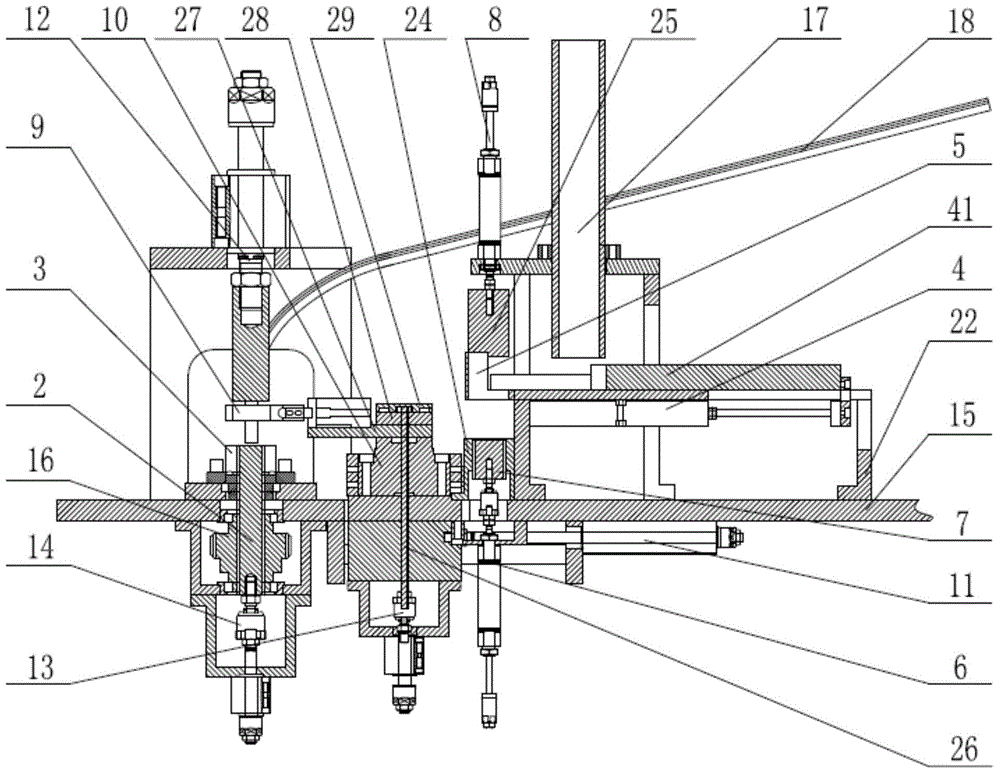

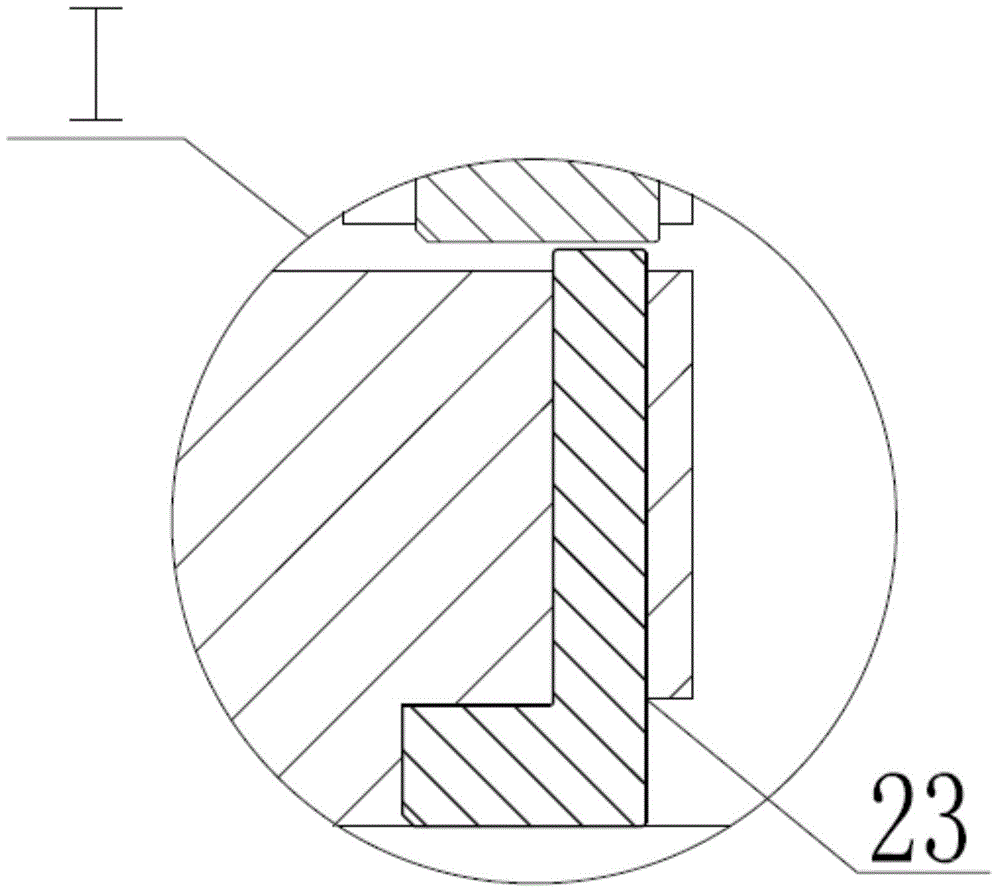

[0031] Two copper plate vibrating plates and one plastic shell vibrating plate are automatically fed to the feed guide rail 18 and the sleeve rod 17 respectively, the servo motor 1 drives the mold core 2 to rotate, and the push piece cylinder 3 drives the commutator copper plate 21 to push in respectively. Core 2. Plastic sleeve push cylinder 4 sends plastic sleeve to fixed sleeve block 5, fixed plastic sleeve cylinder 6 drives plastic sleeve mandrel 7 up, plastic sleeve delivery cylinder 8 goes down, presses plastic sleeve into plastic sleeve mandrel 7, and jacket finger 9 clamps The plastic sleeve, the rotary cylinder 10 drives the jacket finger 9 to rotate, the slider cylinder 11 drives the rotary cylinder 10, and the jacket finger 9 moves forward to the bottom of the compression sleeve cylinder 12 and waits for the sheet arranging process. After the sheet arranging process is completed, the compression plastic sleeve cylinder 12 is pressed down into the plastic sleeve, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap