Flour mixing method for noodles processing

A noodle and flour technology, applied in the direction of dough mixing/kneading method, application, dough mixer, etc., can solve the problems of low degree of automation, excessive volume, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

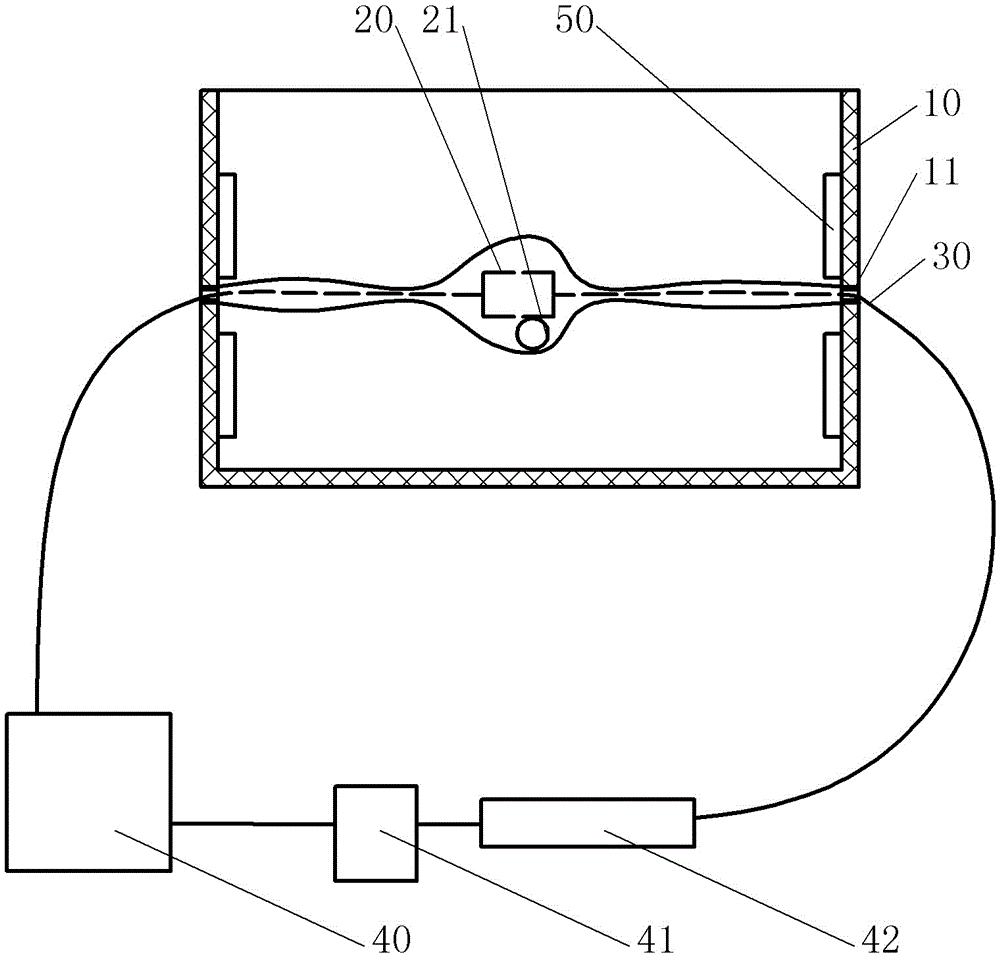

Image

Examples

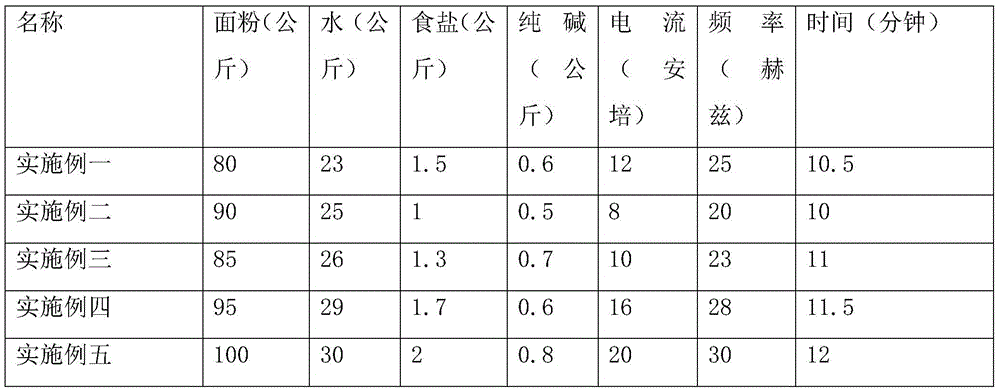

Embodiment 1

[0021] Embodiment 1 is basically as follows:

[0022] The dough kneading method for noodle processing, using the noodle kneading device for noodle processing, comprises the following steps:

[0023] (1) Adding noodles and adding water: add 80 kilograms of flour and 23 kilograms of water into the barrel of the noodle mixing device for noodle processing;

[0024] (2) Add salt: add 1.5 kilograms of salt to the barrel of the noodle-making device for noodle processing;

[0025] (3) add soda ash: add 0.6 kilograms of soda ash in the barrel of noodle processing and dough device;

[0026] (4) Kneading control: start the AC power supply, adjust the current of the AC power supply to 12A, adjust the frequency to 25HZ, and the kneading time is 10.5min;

[0027] (5) Turn off the AC power and take out the dough.

[0028] Among them, it should be noted that:

[0029] (1) Adding water to the dough: Only when the protein and starch in the flour fully absorb water can a good dough mixing ef...

Embodiment 2

[0048] The difference with embodiment one is: the flour in the step (1) is 90 kilograms, and the water is 25 kilograms; The salt in the step (2) is 1 kilogram; The soda ash in the step (3) is 0.5 kilogram; The current of the AC power supply is 8A, the frequency is 20HZ, and the surface time is 10min.

Embodiment 3

[0050]The difference with embodiment one is: the flour in the step (1) is 85 kilograms, and the water is 26 kilograms; The salt in the step (2) is 1.3 kilograms; The soda ash in the step (3) is 0.7 kilograms; The current of the AC power supply is 10A, the frequency is 23HZ, and the surface time is 11min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com