Water turbine volute welding method

A welding method and technology for hydraulic turbines, which are applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unsatisfactory welding quality of the volute of the hydraulic turbine, and improve the one-time pass rate of welding, stable welding quality of the volute, and welding. The effect of cycle shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

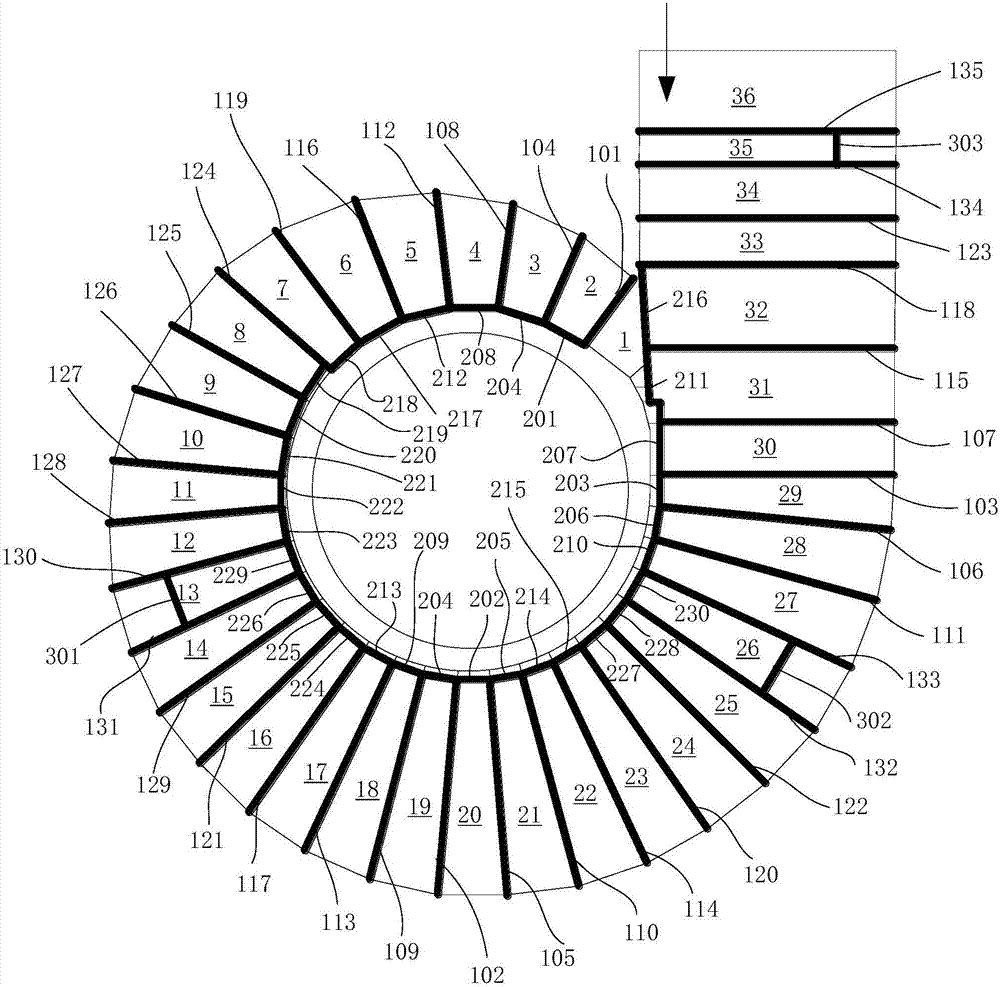

[0051] In view of the problems mentioned in the background technology, for this reason, after summarizing the experience in the welding of the turbine volute, and according to the characteristics of the high-strength steel used for the turbine volute, the welding process and process of the circular seam of the volute and the longitudinal seam of the transition plate have been studied and adjusted. , and proposed the "two rings and one disc" welding process for the turbine volute. Practice has proved that the "two rings and one plate" welding process not only realizes the simultaneous welding of the circular seam and longitudinal seam of the volute, effectively ensures the welding ventilation conditions, significantly improves the welding construction environment, and stabilizes the welding quality of the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com