Welding tool clamp fixing and shaping metal structure bottom frame

A technology for welding fixtures and metal structures, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve problems that affect production efficiency, waste materials, affect work efficiency, etc., and achieve improved efficiency, less deformation, and welding accuracy Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation of the welding fixture for fixing and shaping the bottom frame of the metal structure of the present invention will be further described below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

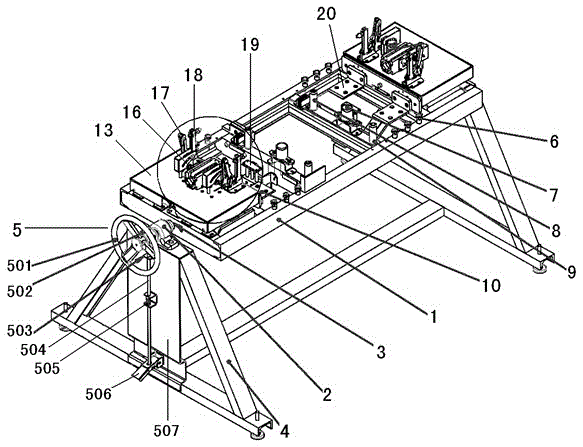

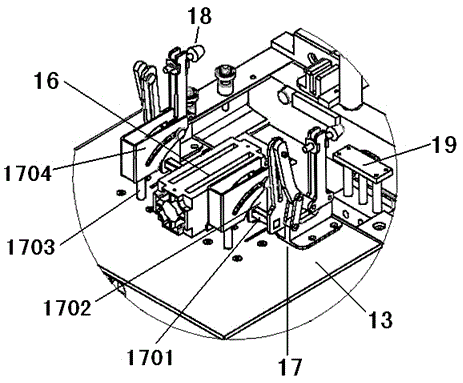

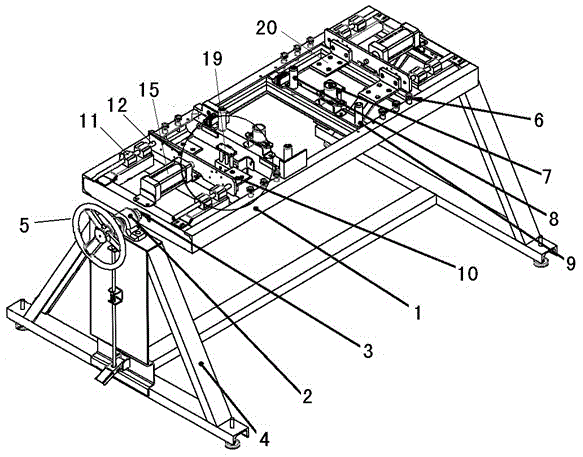

[0040] see figure 1 . A welding fixture for fixing and shaping the bottom frame of a metal structure, including a bracket 1, a rotating shaft 2, a bearing 3, a stand 4, a rotation positioning mechanism 5, an end cover positioning wheel 6, a middle positioning pin 7, and a front positioning pin 8, rear gear positioning pin 9, fixed lock sleeve 10, movable chuck 13, locking cylinder 16, locking mechanism 17, rotating rod 1701, positioning pin crank arm 1702, positioning pin 1703, positioning clip crank arm 1704, return spring 1705, Positioning clip 18, demoulding cylinder mechanism 19 and L-shaped supporting plate 20.

[0041] The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com