Automatic assembling machine for door handle

An automatic assembly machine, door handle technology, applied in the direction of assembly machine, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, low efficiency, and a large amount of manpower, achieve a high degree of automation, reduce labor costs, improve The effect of work efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

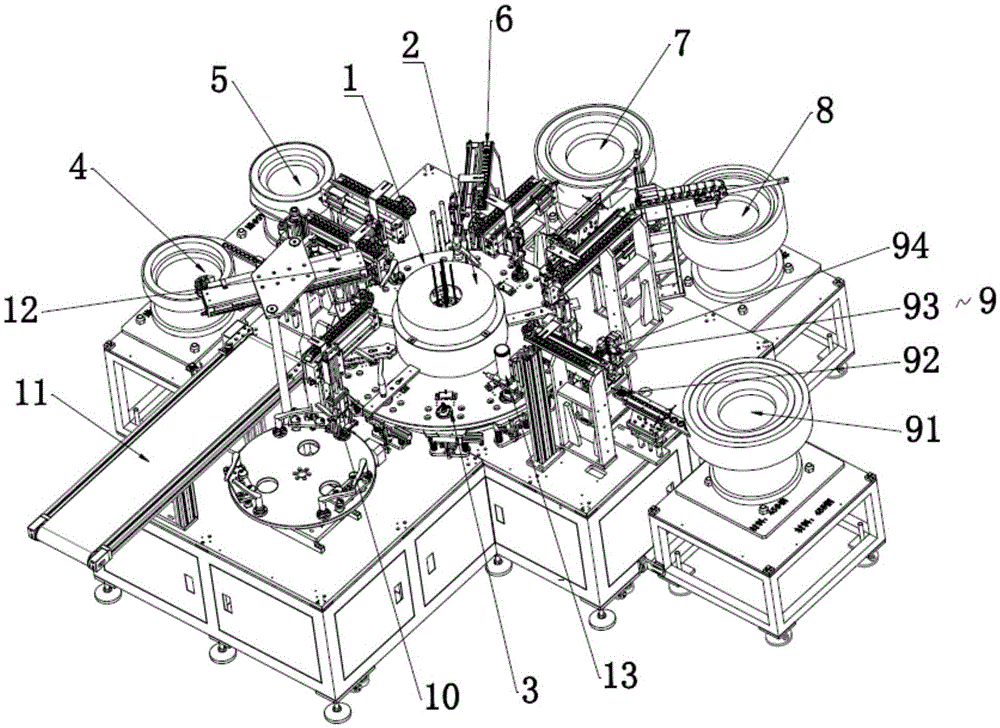

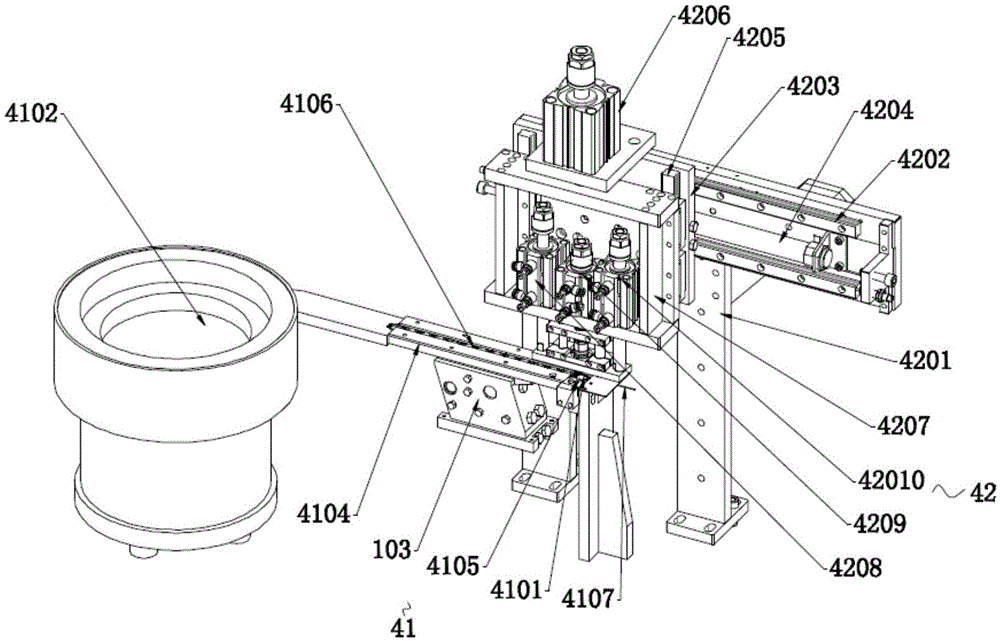

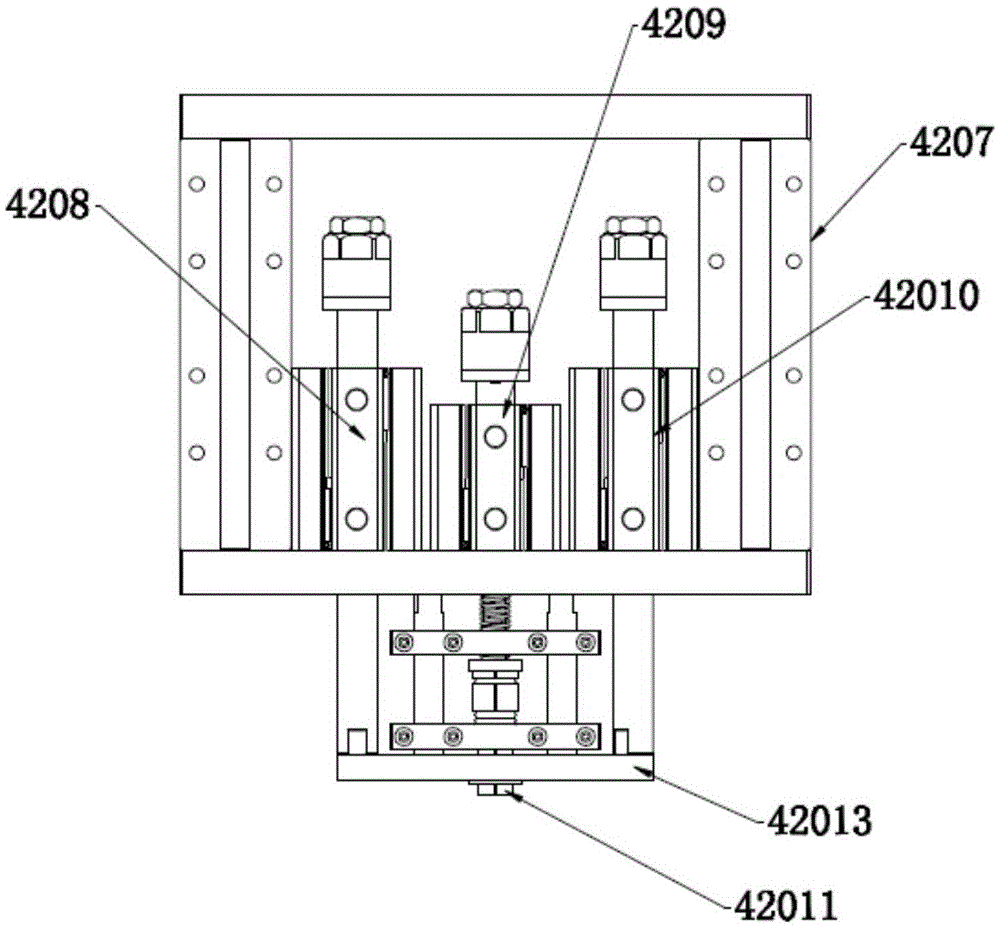

[0022] like figure 1 , this embodiment provides an automatic door handle assembly machine, including a disc rotation mechanism, the disc rotation mechanism includes a turntable 1 and a turntable drive mechanism 2 connected to the turntable, and the circumferential outer side of the turntable 1 is evenly and equidistantly distributed There are a number of jigs 3, and along the rotation direction of the turntable 1, there are sequentially provided with a circlip automatic feeding mechanism 4 that automatically puts the circlips into the jig 3 one by one, and a second gasket that automatically puts the first gaskets into the jig 3 one by one. A gasket feeding mechanism 5, the second gasket feeding mechanism that automatically puts the second gaskets into the jig 3 one by one 6, the wave crest gasket feeding mechanism that automatically puts the wave gaskets into the jig 3 one by one 7. Automatically put the stoppers one by one into the stopper feeding mechanism in the jig 3. 8. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com