Splitting machine

A slitter, organic technology, applied in metal processing and other directions, can solve problems such as uneven paper discharge and paper jam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

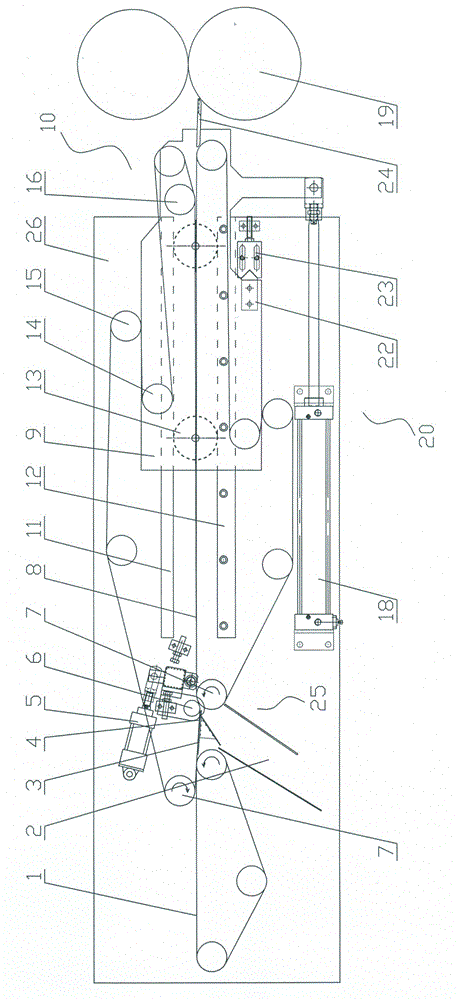

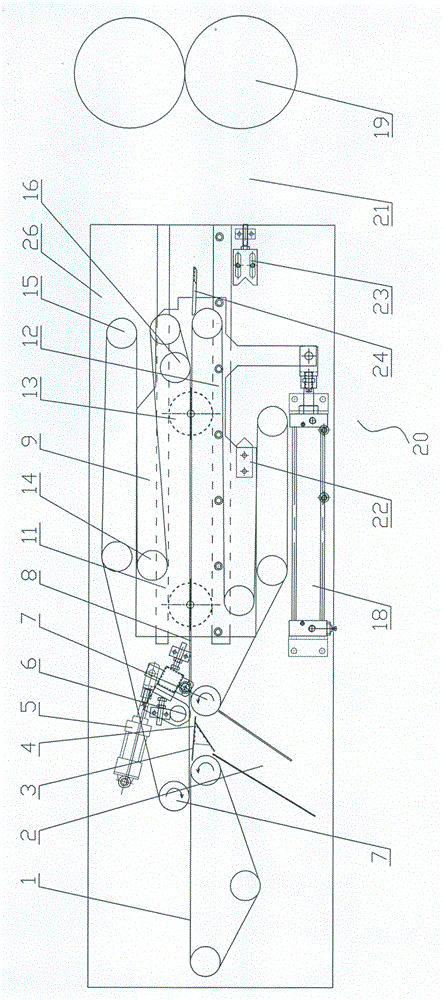

[0018] With reference to the accompanying drawings, this kind of slitter includes a frame 26, a slitting mechanism 19, a paper conveying mechanism 20 and a waste rejecting mechanism 25, and the paper conveying mechanism 20 is arranged at the rear of the slitting mechanism 19, and the paper conveying mechanism Mechanism 20 comprises upper conveyer belt 3, lower conveyer belt 8 and cardboard 24, and described cardboard 24 is arranged on the front of upper conveyer belt 3 and lower conveyer belt 8, and described paper conveyer mechanism 20 is arranged on the mobile car 9, Described mobile vehicle 9 is connected with power source 18, and described power source 18 can adopt cylinder, and described frame 26 is provided with the track that horizontally moves for mobile vehicle, and described track comprises upper track 11 and lower track 12, and described The mobile cart 9 is provided with a pulley 13, and the pulley 13 is arranged on the upper rail 11 and the lower rail 12. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com