Semi-active suspension based on magnetically controlled shape memory alloy

A semi-active suspension, memory alloy technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve problems such as hydraulic oil leakage, achieve elimination of hydraulic oil leakage, fast response frequency, and high control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

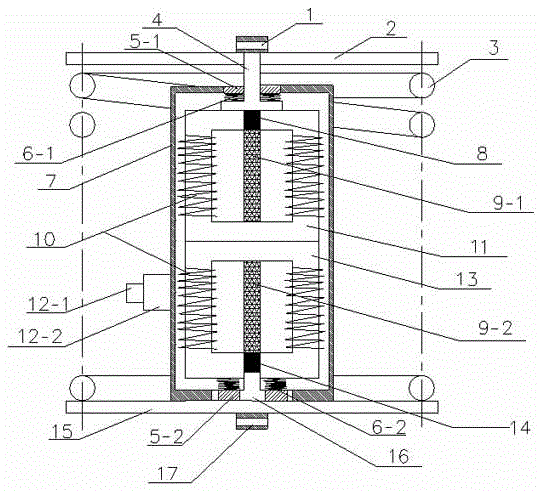

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

[0025] Wherein, the magnitude of the current in the excitation coil can be actively adjusted by the controller, the larger the excitation current, the stronger the magnetic field generated by the iron core.

[0026] Among them, the upper and lower ejector rods are made of non-magnetic material with great rigidity, one part is against the iron core, and the other end is in contact with the magnetic control memory alloy rod, so as to ensure that the alloy rod is only generated in the direction of the shock absorber tappet. deformation.

[0027] Wherein, the magnetically controlled shape memory alloy rod is closely connected with the shock absorber tappet and the ejector rod through the pre-tightening force exerted by the disc spring. And the magnetic control memory alloy rod just forms a closed magnetic circuit with the iron core, and the magnetic force line passes alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com