A drug automatic storage system based on a circular shuttle system

A storage system and shuttle car technology, applied in the field of automatic storage systems for medicines, can solve the problems of low accuracy, low efficiency of three-dimensional warehouse and workshop scheduling, etc., to improve the accuracy, the ability to quickly enter and leave the warehouse, and improve the level of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

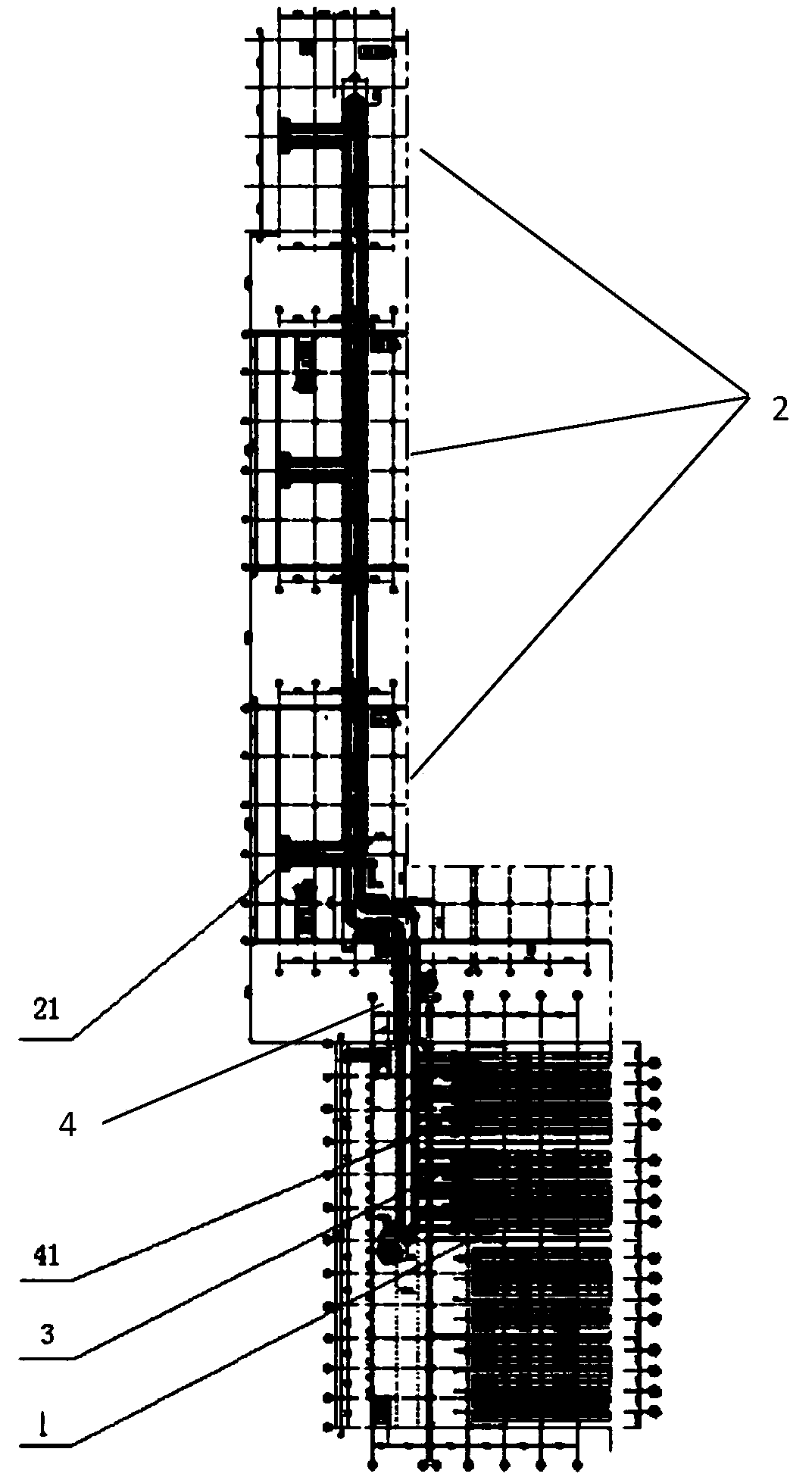

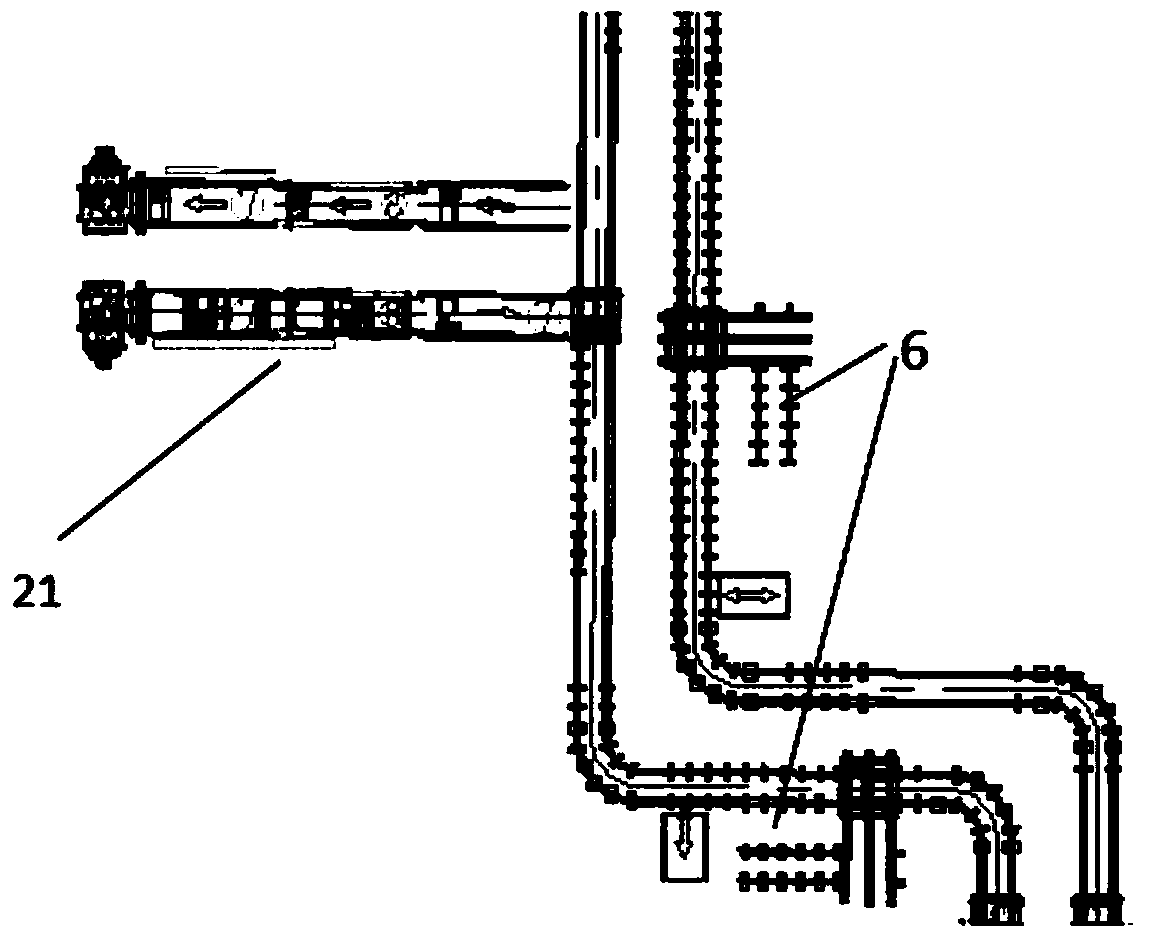

[0040] The system is equipped with No. 1 workshop: oral liquid workshop, No. 2 workshop: honey pill workshop, No. 3 workshop: small pill workshop and No. 4 three-dimensional warehouse 1, each workshop and three-dimensional warehouse 1 are arranged in sequence, and three-dimensional warehouse 1 is divided into 4 partitions , 4 roadway stackers in each area, 16 in total. Among them, the first floor of the three-dimensional warehouse adopts straight-rail RGVs for inbound and outbound operations, one for each area, a total of four. The second floor of the three-dimensional warehouse 1 adopts 8 sets of circular shuttle vehicles to dispatch goods with each workshop. The circular shuttle vehicles shuttle in the interlayer of the workshop, and the palletized goods are transported to each floor of the workshop by the elevator. Considering the convenience of maintenance of the shuttle vehicles, there is a shuttle in the interlayer Car maintenance area6.

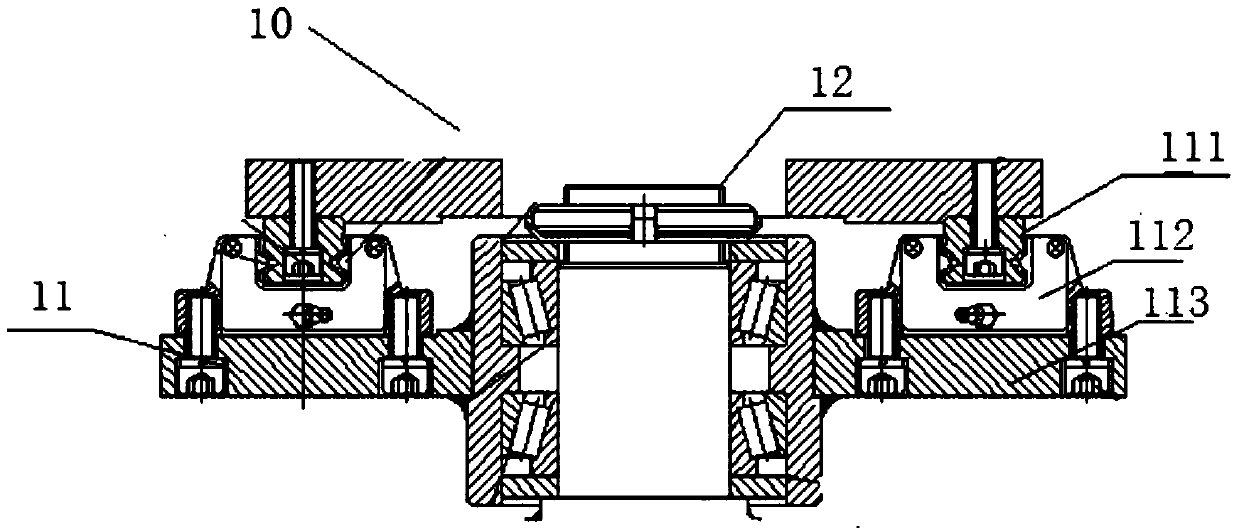

[0041] Such as Figure 4 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com