A nano-VO2 film with superhydrophilic self-cleaning and intelligent temperature control functions and its preparation method

A self-cleaning, super-hydrophilic technology, applied in the field of nano-VO2 film and its preparation, can solve the problems of inability to reduce the phase transition temperature of vanadium dioxide, the application limitation of vanadium dioxide film, and the self-cleaning of smart windows. Good intelligent temperature control effect, excellent phase change performance, and low infrared light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a VO with superhydrophilic self-cleaning and intelligent temperature control functions 2 The preparation method of film, its step is as follows:

[0034] 1) Mix the tetravalent vanadium source and the tungsten source with the solvent alcohol, stir evenly and leave it to stand for aging to obtain a precursor solution, wherein the molar ratio of the hexavalent tungsten in the tungsten source and the tetravalent vanadium in the tetravalent vanadium source is ( 0-10%): 1;

[0035] 2) The obtained precursor solution is directly and uniformly coated on the substrate, and annealed in an inert gas atmosphere to obtain a VO with superhydrophilic self-cleaning and intelligent temperature control functions. 2 film.

Embodiment 1

[0037] A VO with superhydrophilic self-cleaning and intelligent temperature control functions 2 The preparation method of film, its step is as follows:

[0038] 1) Take 1g of vanadyl acetylacetonate (VO(acac) 2 ) into a beaker, add 30ml of methanol, place it on a magnetic stirrer and stir for 24 hours, leave it to age for 48 hours, and obtain a dark blue precursor solution;

[0039] 2) Add the precursor solution dropwise on the surface of the quartz glass on the spin coater, spin coat at a speed of 2000r / min, dry it and place it in a tubular muffle furnace, and anneal it under argon protection at a high temperature of 600°C for 1h. That is, a VO with superhydrophilic self-cleaning and intelligent temperature control functions is obtained. 2 film.

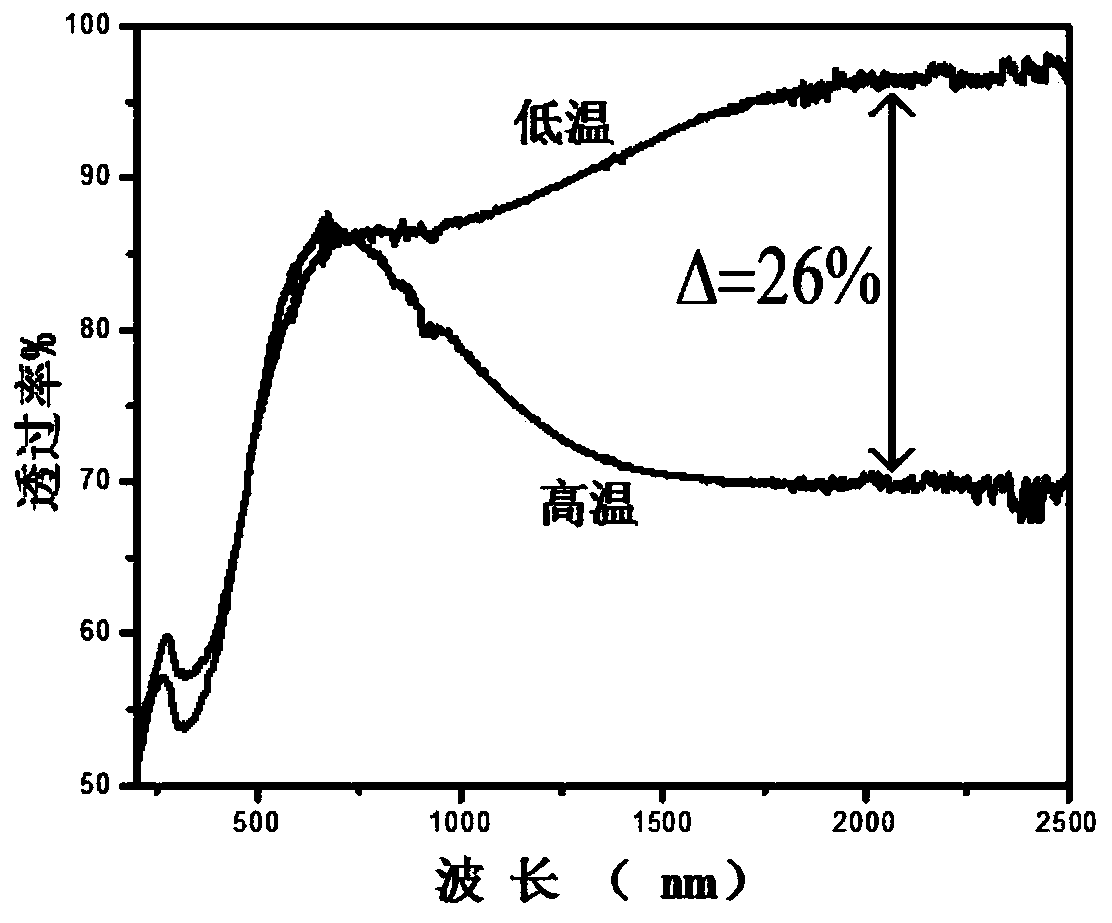

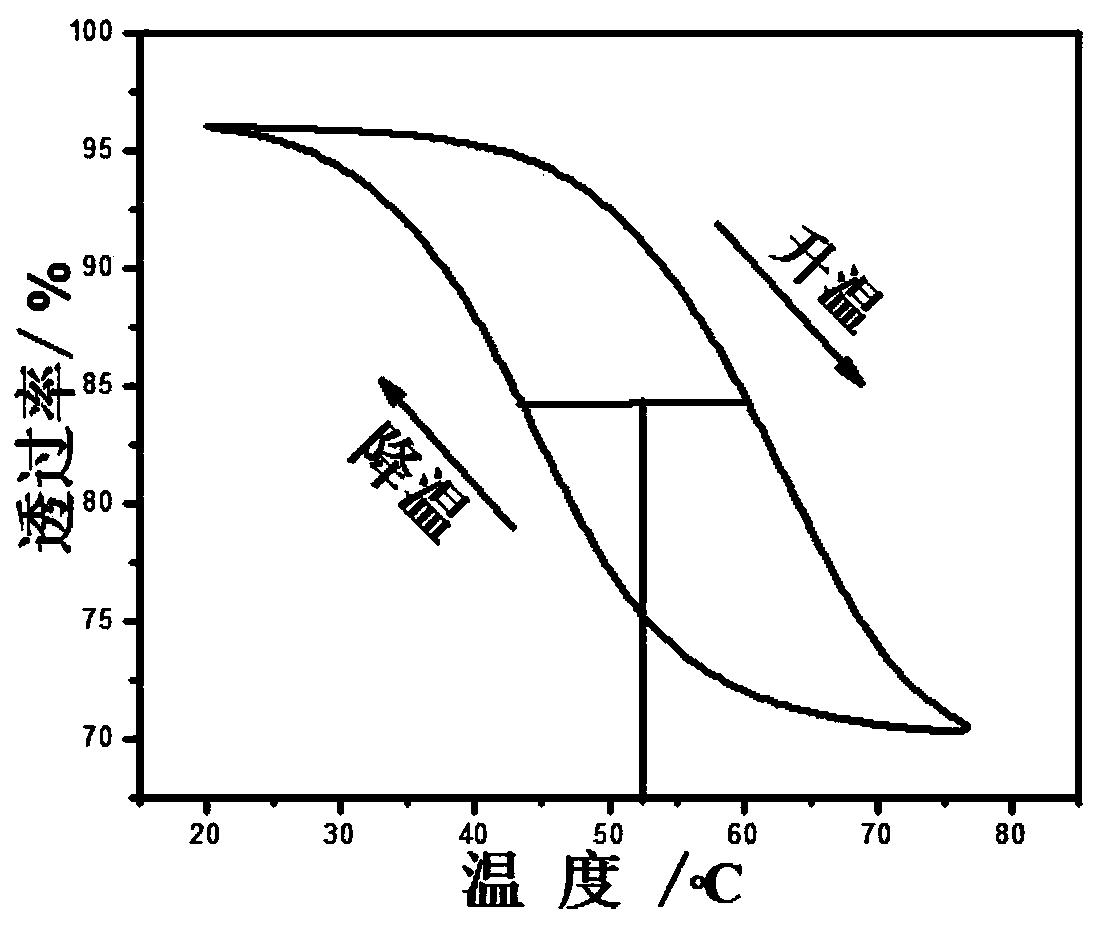

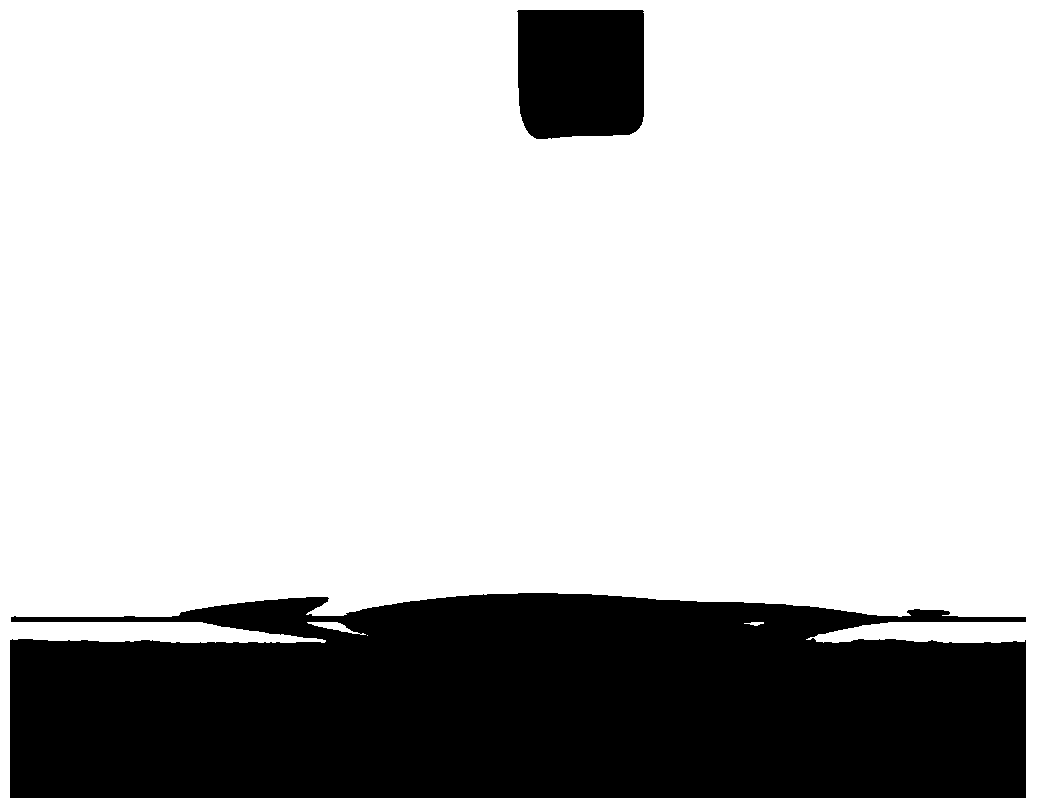

[0040] figure 1 , figure 2 , Figure 4 (a) are the UV, thermal hysteresis curve and scanning (SEM) spectrum of the film obtained in this embodiment, respectively. It can be seen from the UV spectrum that the prepared vanadiu...

Embodiment 2

[0042] A VO with superhydrophilic self-cleaning and intelligent temperature control functions 2The preparation method of film, its step is as follows:

[0043] 1) According to the molar ratio of hexavalent tungsten and tetravalent vanadium is 0:1, take 1g of vanadyl oxalate (VOC 2 o 4 ·5H 2 O) in a beaker, add 50ml of ethanol, place it on a magnetic stirrer and stir for 72 hours, leave it to age for 96 hours, and obtain a dark blue precursor solution;

[0044] 2) Add the precursor solution dropwise on the surface of the glass substrate on the spin coater, spin coat at a speed of 6000r / min, put it in a tubular muffle furnace after drying, and anneal for 1.5h under nitrogen protection at a high temperature of 500°C. That is, a VO with superhydrophilic self-cleaning and intelligent temperature control functions is obtained. 2 film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com