A device and method for improving the uniformity of electroplating in a VCP electroplating line

A technology of uniformity and electroplating line, which is applied in the field of devices for improving the electroplating uniformity of VCP electroplating lines, can solve the problems of uneven current distribution of circuit boards, poor conductivity of stainless steel horizontal frame, uneven thickness of electroplating layer, etc., so as to improve the uniformity of electroplating. , The effect of improving electroplating efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

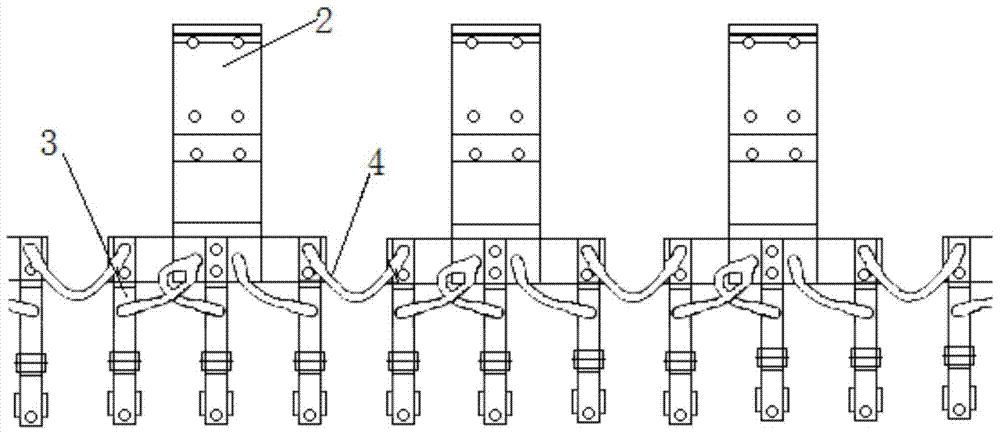

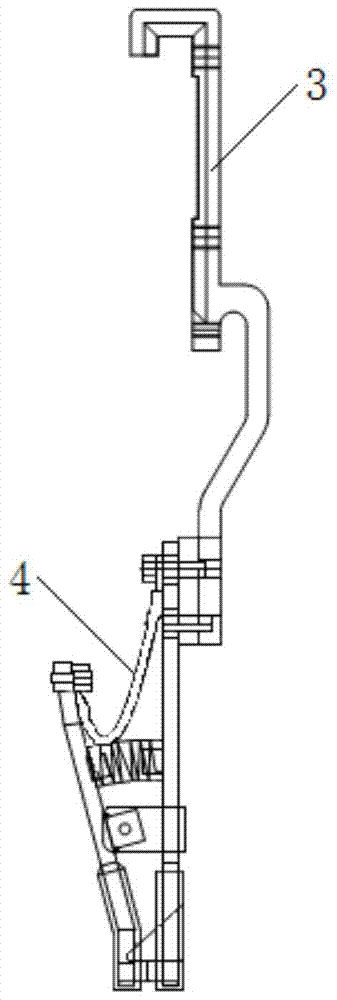

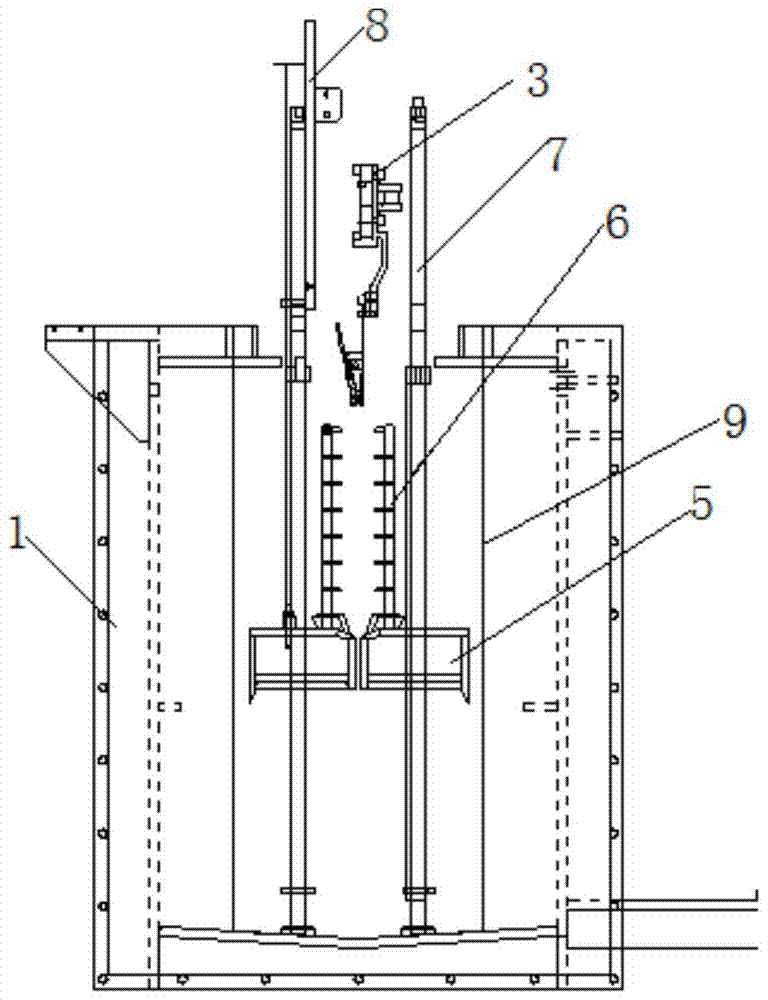

[0028] This embodiment provides a device for improving the uniformity of VCP plating line plating, such as Figure 1-3 As shown, the electroplating tank 1 is included, the electroplating tank 1 is a square tank, and the inside of the tank is filled with electroplating liquid, and a flying bus 2 is arranged above the electroplating tank 1, and the flying bus 2 is fixed on a guide rail and a chain, and the guide rail and The chain drives the flybar 2 to perform circular motion above the electroplating tank 1, the middle position of the guide rail of the fixed flybar 2 is connected to the negative pole of the device power supply, and the flybar 2 is fixedly provided with a clamp 3 for clamping the circuit board , each flybar device is composed of at least three fixtures 3, the main material of the flybar 2 and the fixture 3 is stainless steel, which is conductive. In this embodiment, each flybar 2 is composed of three fixtures 3, and each flybar Adjacent clamps 3 in the bus 2 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com