Isolation processing method of polluted groundwater

A treatment method and technology for groundwater, applied in construction, infrastructure engineering, etc., can solve the problems of horizontal anti-seepage structure damage, seepage, anti-seepage failure, etc., and achieve the effect of reducing engineering quantity, improving control efficiency, and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings.

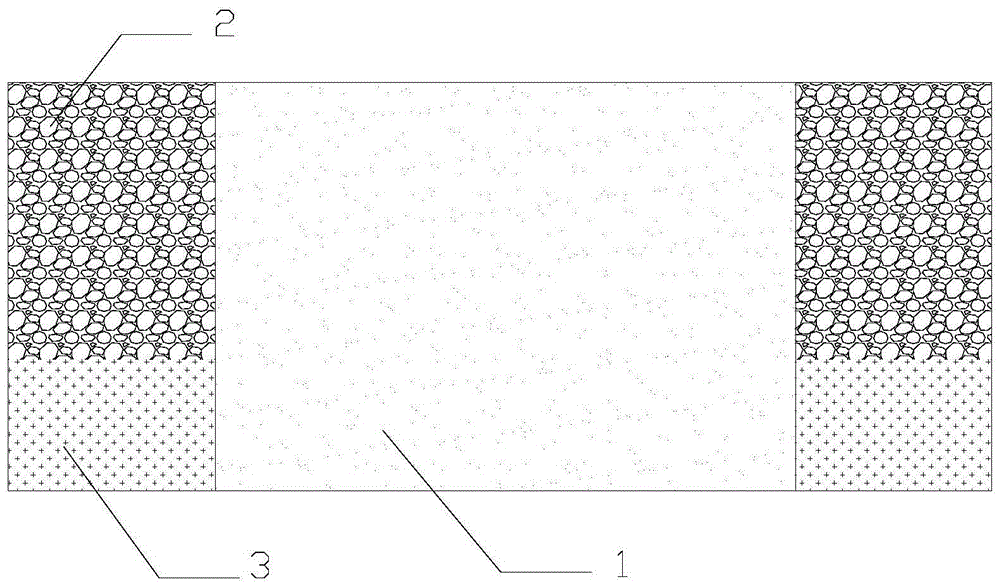

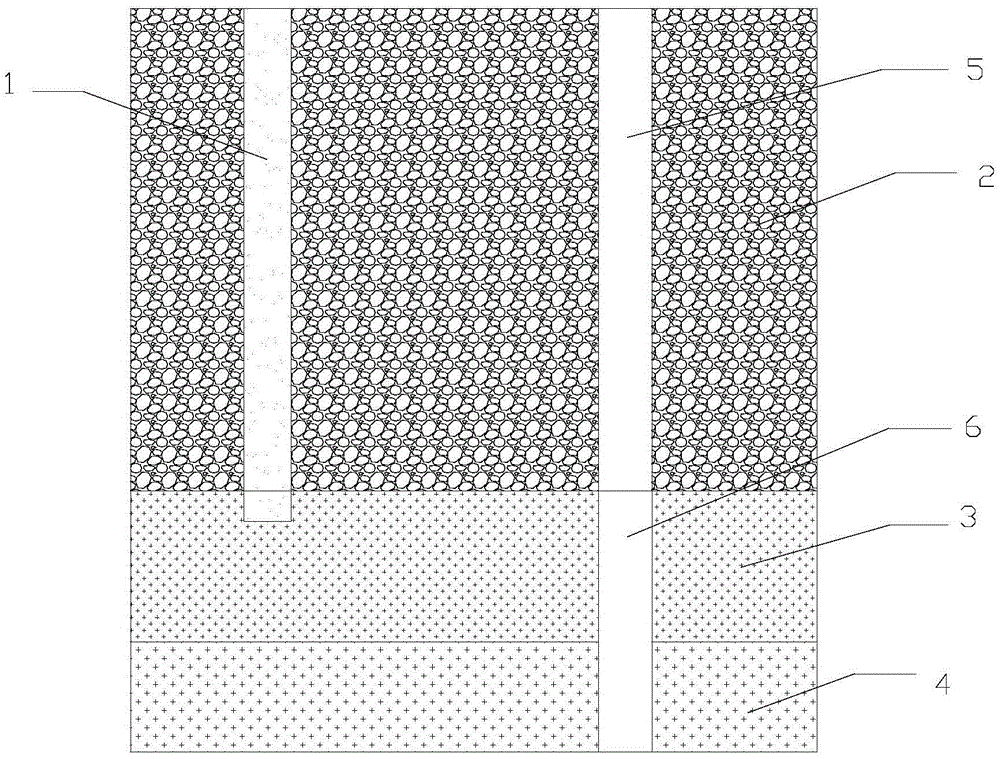

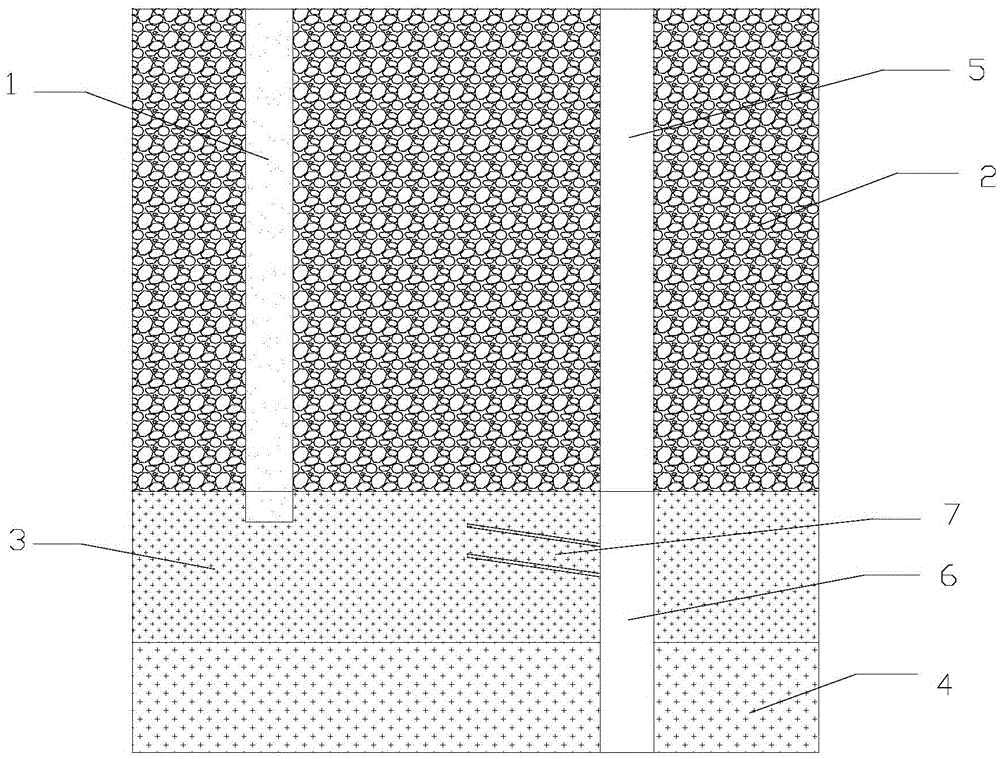

[0022] The isolation treatment method of the present invention combines three methods of "vertical seepage prevention system", "groundwater vertical and horizontal drainage and water level dynamic control system" and "groundwater quality dynamic monitoring system" to achieve the purpose of seepage prevention. Such as figure 1 , 2 As shown in 3, the vertical anti-seepage system 1 can be an underground continuous wall or a grouting curtain, and the depth required to enter the moderately weathered rock 3 is not less than 3m; the "groundwater vertical and horizontal drainage and water level dynamic control system" include: vertical shaft 5 , Horizontal drilling or flat tunnel 7, groundwater level monitoring facilities, automatic drainage facilities, etc.; "groundwater quality dynamic monitoring system" includes indicators, dynamic detection equipment, data transmission equipment.

[0023] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com