Partition joint device and construction method of prefabricated sandwich insulation dense rib composite exterior wall panel

A composite exterior wall panel and prefabricated technology, which is applied in thermal insulation, building thermal insulation materials, and building material processing, can solve the problems of loose joints, rainwater flowing into gaps, and infiltrating structural layers, so as to avoid cold ( Thermal) bridge effect, improve thermal performance, prevent extrusion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

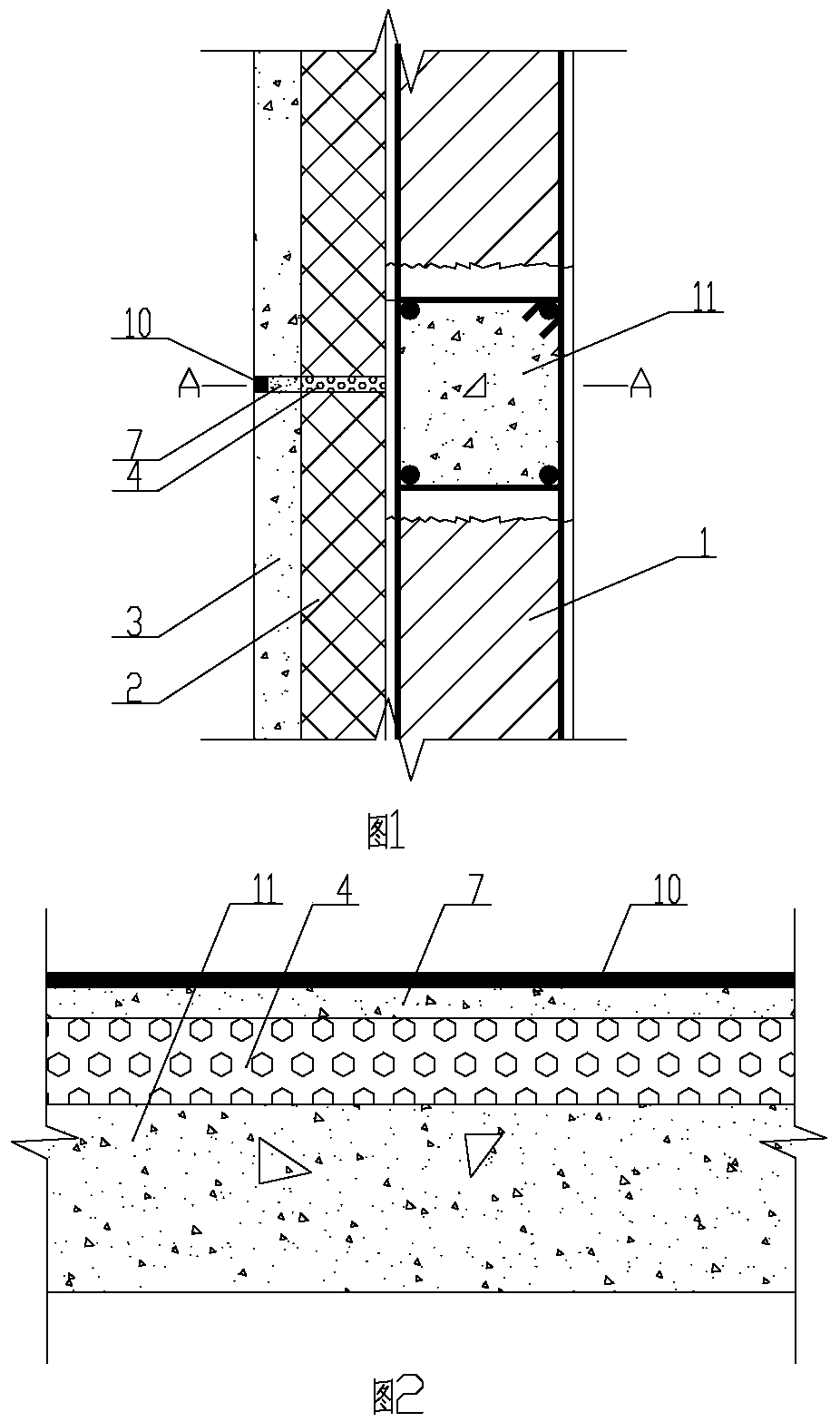

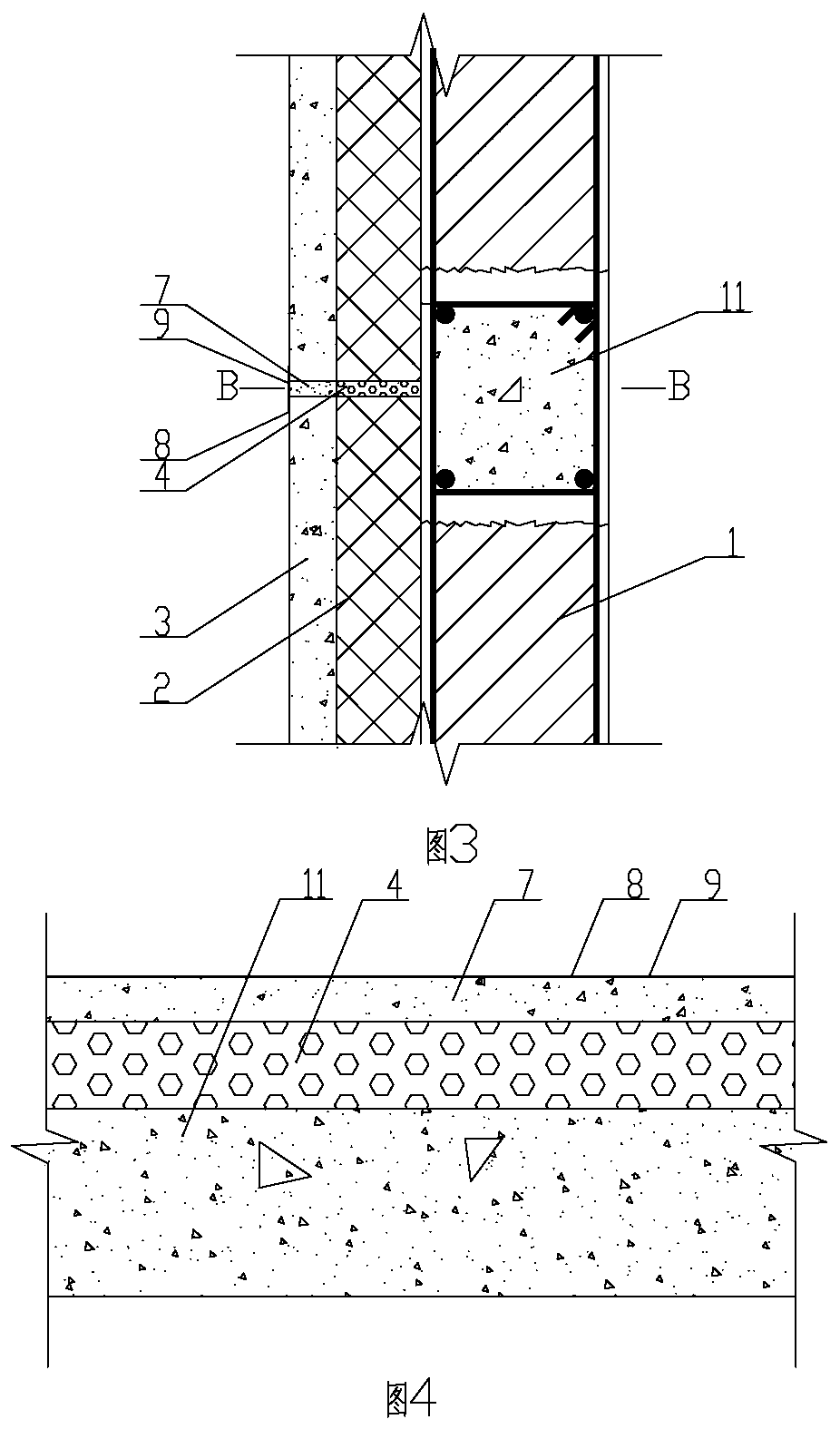

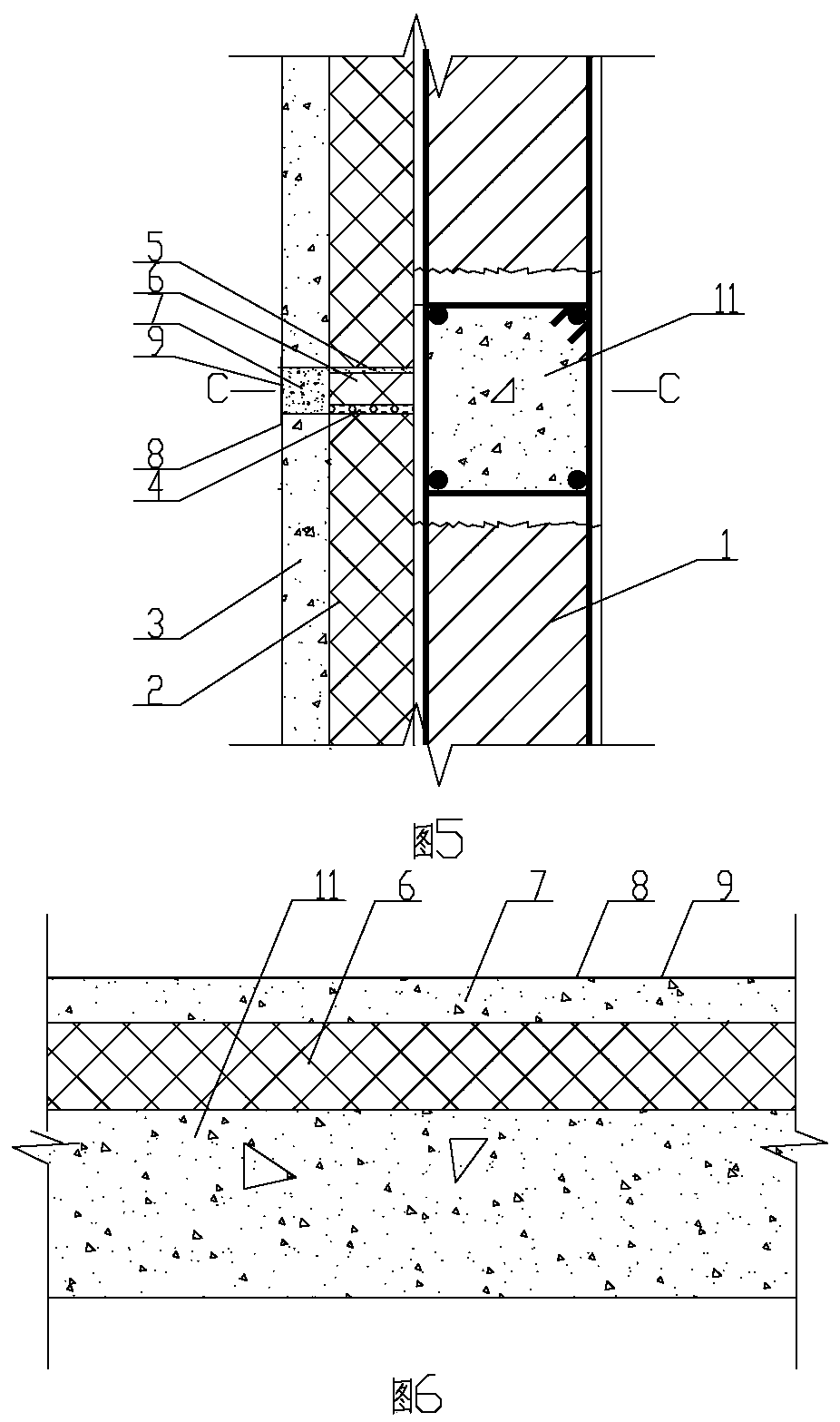

[0030] Embodiment 1, as shown in accompanying drawings 1, 2, 3, 4, 5, 6, 7, and 8, the assembled sandwich thermal insulation rib composite exterior wall panel partition device includes inner filler, outer filler and At least two prefabricated sandwich thermal insulation dense rib composite exterior wall panels; the prefabricated sandwich thermal insulation dense rib composite external wall panels include structural layer 1, thermal insulation layer 2 and protective layer 3, and two adjacent assembled sandwich thermal insulation dense ribs The inside of the separation joint formed by the composite exterior wall panels is fixed with an inner filler, and the outer surface of the inner filler is lower than or flush with the outer surface of the thermal insulation layer 2 of the assembled sandwich thermal insulation rib composite outer wall panel; The external filler is fixed on the outside of the separation joint formed by the sandwich thermal insulation dense rib composite externa...

Embodiment 2

[0031] Embodiment 2, as an optimization of the above embodiment, as shown in Figures 1, 2, 3, and 4, when the width of the separation joint formed by two adjacent assembled sandwich insulation dense rib composite exterior wall panels is 5 mm to 15 mm, The inner filler is a polyurethane foaming agent 4; the outer surface of the polyurethane foaming agent 4 is lower than the outer surface of the insulation layer 2. The outer surface of the polyurethane foaming agent 4 is lower than the outer surface of the insulation layer 2 by 5mm to 10mm.

Embodiment 3

[0032] Embodiment 3, as an optimization of the above embodiment, as shown in Figures 5, 6, 7, and 8, when the width of the separation joint formed by two adjacent assembled sandwich insulation dense rib composite exterior wall panels is greater than 15mm to 40mm , the inner filling includes polyurethane foaming agent 4, glass fiber anti-cracking mortar layer 5 and insulation board filling strip 6; the insulation board filling strip 6 is located inside the separation joint formed by two adjacent assembled sandwich insulation dense rib composite exterior wall panels In the middle, one side of the insulation board filling strip 6 is bonded together with the insulation layer 2 through the glass fiber anti-crack mortar layer 5, and polyurethane foaming agent 4 is filled between the other side of the insulation board filling strip 6 and the insulation layer 2 , Polyurethane foaming agent 4, glass fiber anti-cracking mortar layer 5 and insulation board filling strip 6 are flush with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com