Modularized annular unfolding type container house

A container and unfolding technology, applied to photovoltaic modules, photovoltaic module support structures, roofs, etc., can solve the problems of single style, small use area, and poor thermal insulation performance of container houses, so as to improve external thermal insulation performance, structural shockproof, The effect of less manpower and man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

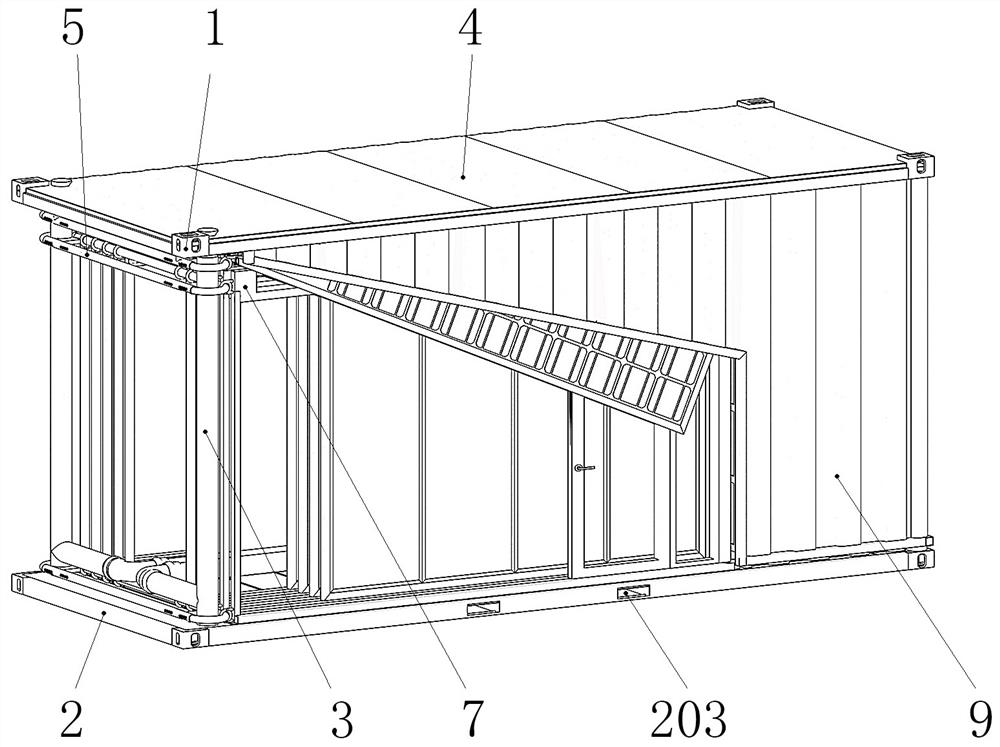

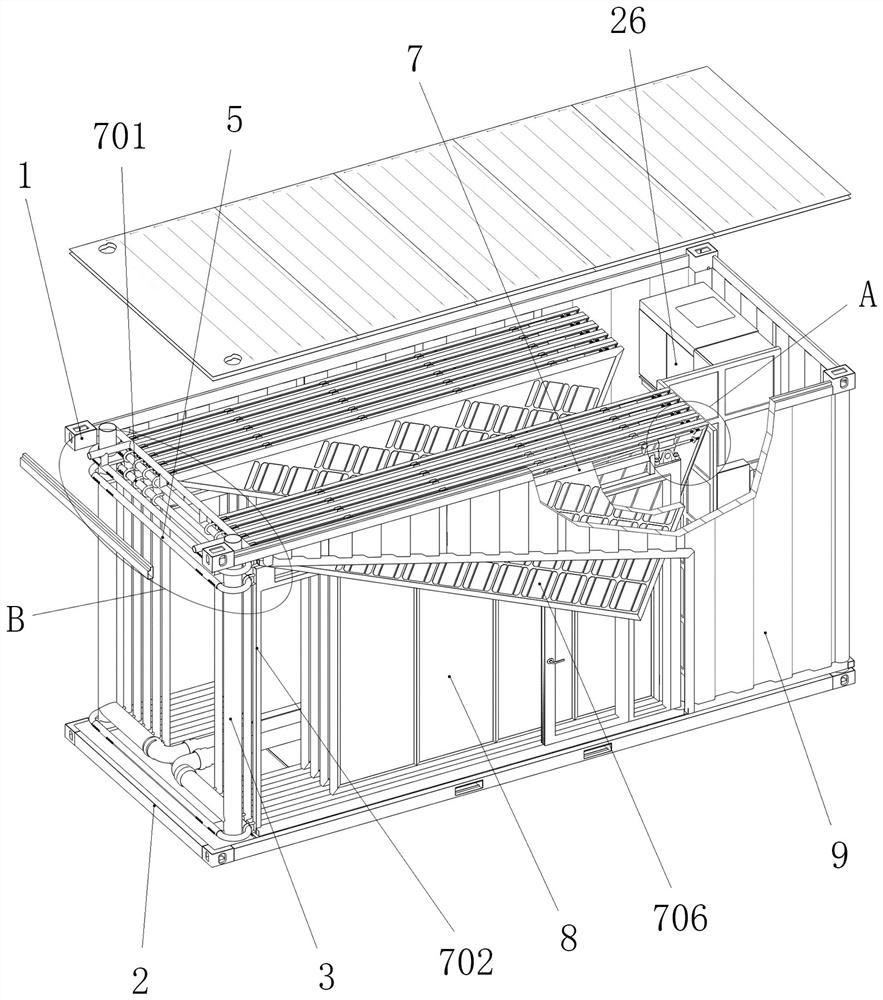

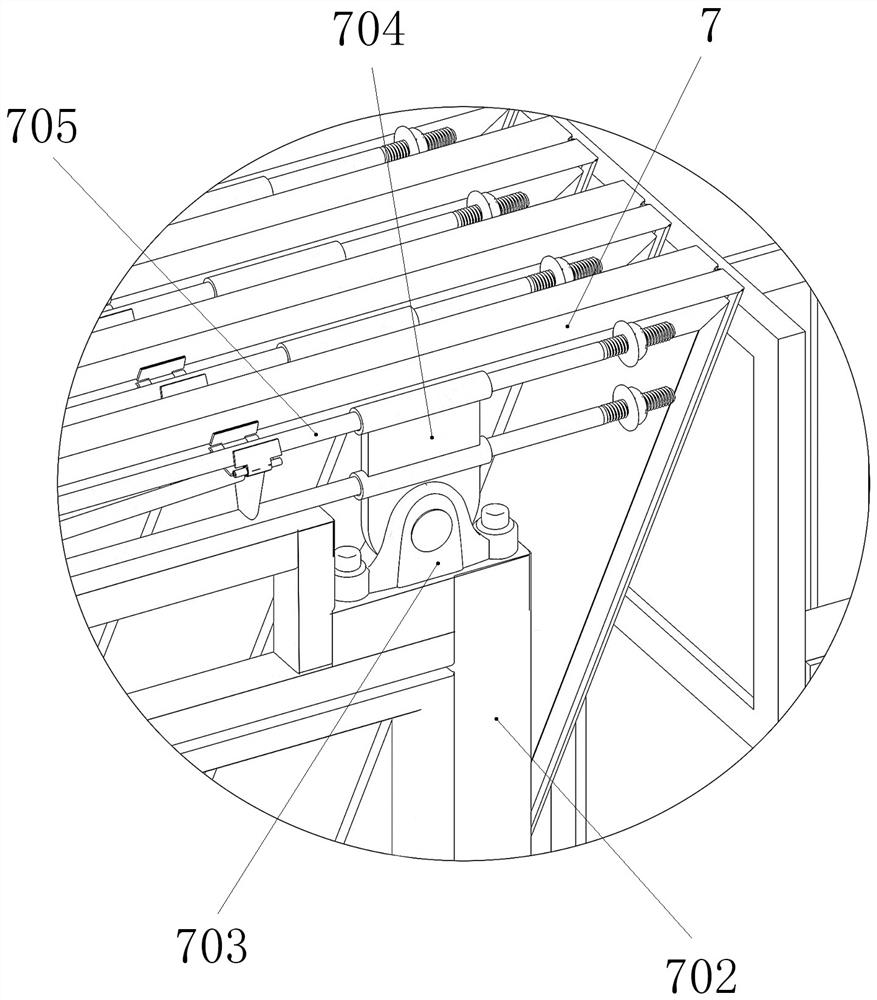

[0046]The modular ring-shaped expandable container house includes a container body and a kitchen and bathroom system. The container body includes an upper frame, corner fittings, corner columns, wall panels, a lower frame, and a forklift port. One end of the container body The two corner columns of the container body are correspondingly arranged on the inner side of the corner piece 1; the four corner columns of the container box are slidingly fitted lifting columns 3, and the lifting columns are composed of an inner tube column and an outer tube set on the inner tube column 301. Composed of column 302, a lifting limit piece is arranged on the lifting column to realize the limit after the container body is raised; an annular pipe fitting 5 is arranged around the periphery of the two lifting columns located inside the corner fittings, and the annular pipe fitting The lower and upper parts of the outer pipe string and the upper part of the inner pipe string are respectively conne...

Embodiment 2

[0052] On the basis of Example 1, in order to improve the thermal insulation requirements of container houses, a multi-layer air bag thermal insulation structure composed of multiple multi-layer modular thermal insulation air bags 15 is also provided on the inside of the installed house body. Each multi-layer module The thermal insulation airbags are equipped with inflation valve 30 and airbag connecting rope; after the multi-layer modular thermal insulation airbags are spliced with each other through the groove structure inserted into each other, they are fixedly connected by the airbag connecting rope; the multilayer airbag insulation structure is also connected by The airbag connecting rope is fixedly connected with multiple positions inside the room body.

[0053] Ground beams, floors, roof panels, waterproof tiles, waterproof rubber strips, waterproof cover panels, roof panels, roof decorative strips, roof decorative corners, kitchen and bathroom systems, rain pads, mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com