Concrete prefabricated stair

A technology for concrete and stairs, applied in stairs, stepped structures, treads, etc., can solve the problems of weakening the strength of stairs, easily generating cracks, slowing down the construction progress on site, etc., to achieve the effect of shortening the construction period and enhancing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

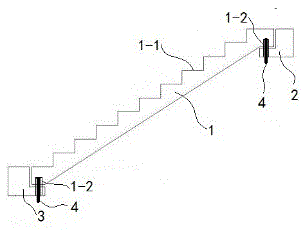

[0012] The present invention will be further explained below in conjunction with the accompanying drawings.

[0013] Such as figure 1 The concrete prefabricated staircase according to the embodiment of the present invention includes a prefabricated staircase 1 and a stepping surface 1-1 of the prefabricated staircase 1, and the stepping surface 1-1 is a water-brushed stone surface. With such a design, the stones on the surface of the step surface are exposed to form a rough surface, and there is no need for manual chiseling and chopping, and post-work such as pasting tiles on the tread surface can be directly done, which greatly shortens the construction period.

[0014] Further, in the above-mentioned concrete prefabricated staircase, the bottoms of both ends of the prefabricated staircase 1 are provided with threaded holes 1-2 for construction and installation. Such as figure 1 As shown, a prefabricated staircase 1 is installed on a supporting platform, which includes an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com